Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

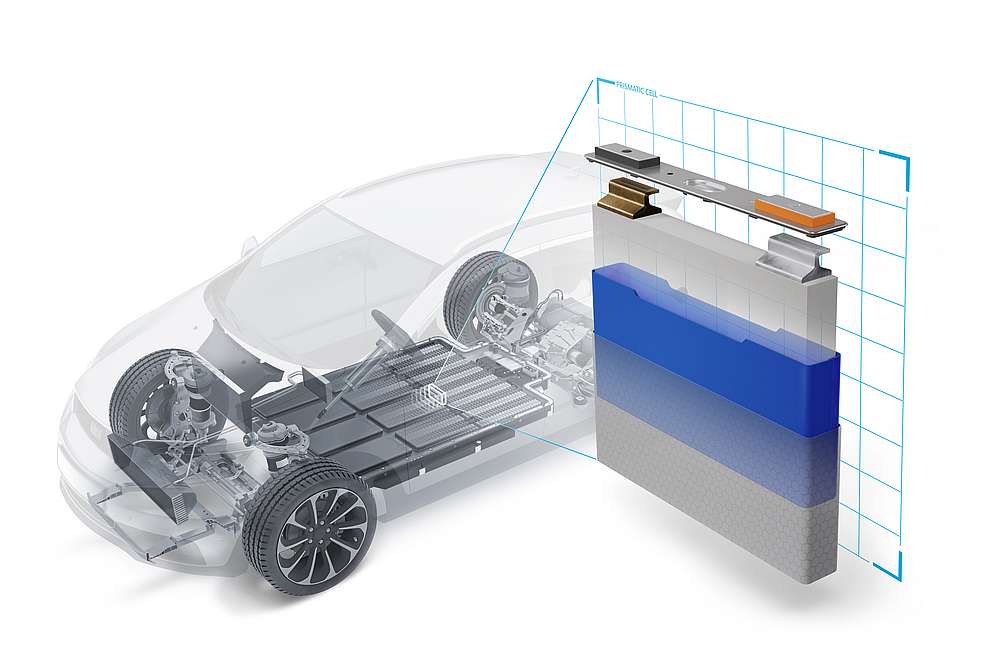

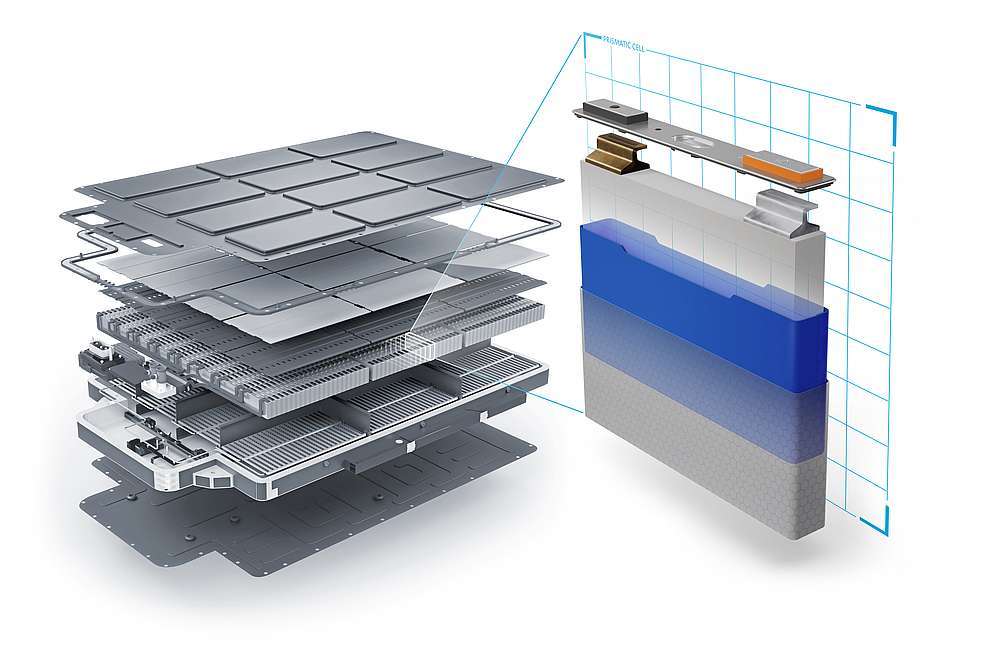

Prismatic Cell Caps and Envelopes

Advanced Battery Cell Caps and Envelopes

FST is introducing two new products in the battery product family

In the rapidly advancing field of E-Mobility, prismatic battery cells are at the forefront of innovation. FST is introducing two new products in the battery product family: advanced battery cell caps and envelopes which offer high energy density, superior thermal management, and robust performance. The structural integrity and protection of these cells are paramount. The Prismatic Cell Caps and Envelopes have been meticulously engineered to meet these needs, ensuring safety, durability, and optimal performance for prismatic battery cells.

Battery Cell Caps Advantages (BCC)

-

Materials Integrity and Compatibility:

The materials used for our battery cell caps are carefully developed and selected to ensure compatibility with a diverse range of electrolytes, guaranteeing no contamination that could disrupt the battery's chemistry. -

Safety Standards:

Materials are certified according to UL 94 V0, which is one of the most stringent flammability standards. -

Sustainability:

The battery cell caps' PFAS-free nature affirms the product's sustainability, aiming to meet long-term environmental goals. This ensures compliance with regulatory requirements and demonstrates FST's continuous commitment to sustainability. -

Material Development – Innovation and Performance:

A specific EPDM has been engineered to meet superior compatibility performance with electrolytes over FKM. -

Sealing and Mechanical Durability:

The sealing component is designed to ensure perfect tightness and robust compression to withstand variable operating conditions, thereby enhancing the overall reliability of the cell. -

Enhanced structural integrity:

Reliable welding solutions are tested under severe conditions to assess their mechanical resistance to peak and fatigue loads, ensuring the durability of the cell.

Battery Cell Envelopes Advantages (BCE)

-

Material Integrity and Compatibility:

All materials in contact with the electrolyte are battery-proven and comply with strict cleanliness requirements, preventing contamination from compromising battery chemistry and functionality. -

Improves Thermal Management Capabilities:

Porous, nonwoven materials facilitate electrolyte flow and improve thermal transfer rates, which helps to keep cells within optimal temperature ranges even during demanding usage scenarios. -

Material Performance:

Nonwoven material is robust and tear-resistant, keeping the cell stack safe during installation. The material’s porous, capillary nature helps to keep the cell stack wetted during the life of the cell with electrolyte. -

More Consistent Cell Manufacturing:

Wettable nonwoven materials do not trap gas bubbles during the filling and formation process which can help to speed up filling times. -

Increased Energy Density:

Free electrolyte flow allows the elimination of certain components, such as shims, streamlining the cell design and production processes making more room for active electrode material. -

Electrolyte Reservoir:

Porous nonwovens can release additional electrolyte when compressed. -

In-Cell Swelling Compensation:

Thick layers of nonwovens enable cell manufacturers to compensate the cell stack growth within the battery cell, eliminating or reducing the need for compensation measures between the cells.

Commitment to Innovation and Quality in Battery Technology

Incorporating these details, FST’s cell products not only advances battery cell manufacturing but also ensures that every aspect, from safety to sustainability, is addressed, reinforcing FST’s commitment to innovation and quality in battery technology.

Download our Prismatic Cell Cap and Envelope Solutions Sheet to learn more about each of their unique characteristics and the benefits they provide.

The Bundled Expertise

of everything you need to know about Prismatic Cell Cap and Envelope

Request Free Solution Sheet