Hydrogen

The Future Is Hydrogen

Sealing Solutions for Hydrogen Applications

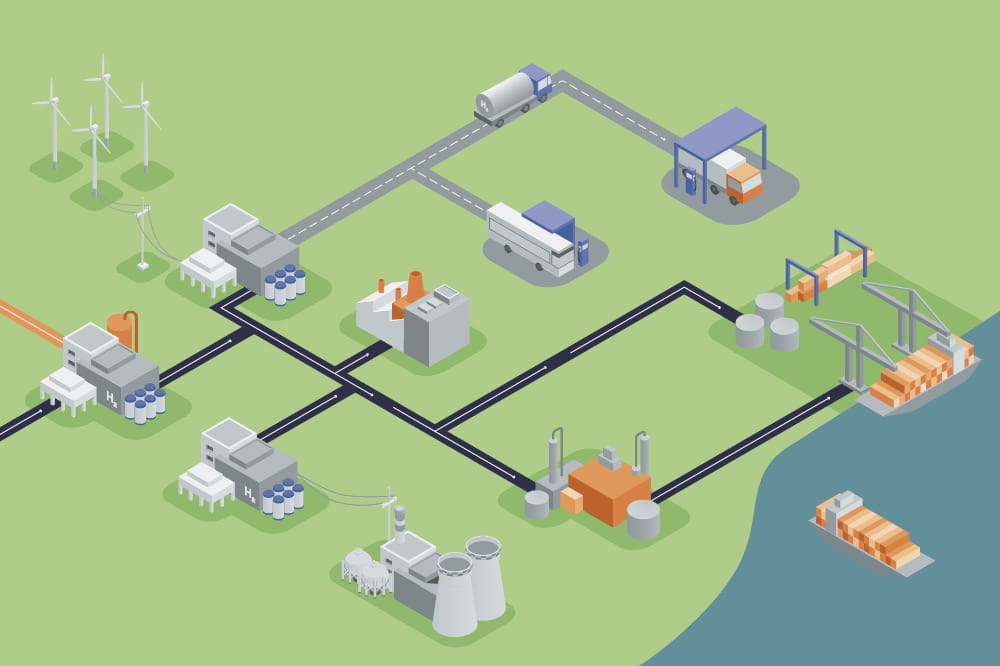

The time has come to tap into green hydrogen’s potential contribution to a sustainable energy system. In the transition towards a hydrogen economy, sealing technology plays a pivotal yet challenging role. As hydrogen becomes increasingly utilized in various sectors such as transportation, energy storage, and industrial processes, the demand for effective seals escalates. One of the primary challenges lies in the unique properties of hydrogen itself, including its small molecular size and high diffusivity, which can lead to leakage over time if not properly contained. Additionally, the compatibility of seal materials with hydrogen and its potential embrittlement effects present formidable hurdles. Moreover, the diverse range of applications within the hydrogen value chain, from high-pressure tanks to intricate fuel cell systems, necessitates versatile sealing solutions capable of withstanding extreme conditions while maintaining long-term reliability. Addressing these challenges requires interdisciplinary collaboration, innovative materials research, and meticulous engineering to ensure the safety, efficiency, and sustainability of the burgeoning hydrogen economy.

H2 Solutions: Dive Deeper

From H₂ Production to Usage: Comprehensive Insights on Production, Distribution, Storage, and Future Applications with Solutions

Explore full spectrum in our webspecial open_in_newNews & Stories on Hydrogen

Discover the new Technical Manual

Become a sealing expert! Our new edition offers an in-depth guide to materials and product expertise, offering a holistic view of sealing technology.

Read now!Discover More on Sealing Solutions for Hydrogen Applications

One Stop Solution: Design and Development Expertise from Freudenberg Sealing Technologies along the Hydrogen Value Chain

With full-service in-house engineering design teams and a network of experienced manufacturing locations worldwide, we can support the design and development of sealing solutions along the hydrogen value chain from production to end use.

Design

Our design teams worldwide are looking forward to bringing their know-how and experience to develop the best sealing solution for you. If you are a developer of fuel cells or electrolyzers, you might be looking for stack sealing solutions that can compensate for manufacturing tolerances, distributes all linear loads evenly across the cell area and facilitates automated mass production. Let us work with you from an early in the development process to help ensure best interplay of all stack components for an economic solution. However, also for advanced design stages, we offer solution for seamless integration and maximum sealing performance and durability.

With our strong background in the automotive and the chemical industry, we offer custom designs for a wide range of static and dynamic seals for valves, compressors, pumps, and engines in the hydrogen and power-to-x applications.

Materials

As the basis for application-specific elastomer development, we can draw on more than 1,500 material formulations. Our expertise in materials and processes makes us a valued partner to help our customers at critical points in the development and meet extended durability targets.

For hydrogen applications, we have developed a series of low-permeation elastomers to ensure the highest efficiency across all use-cases. In many high-pressure applications, rapid gas decompression can jeopardize long-term durability of elastomeric seals. Our compounds are thus tested and optimized to withstand these harsh conditions for maximum seal lifetime.

Specifically for electrochemical energy converters, chemical resistance is a challenge we can overcome with our high-performance elastomers that resist high temperatures, pressures, compressive deformation and even the harsh electrolysis environment. Besides their chemical resistance, these compounds meet high cleanliness requirements and are designed to prevent leaching of any catalyst poisons that could hamper the long-term performance of electrochemical cells.

Testing

At Freudenberg Sealing Technologies, material testing and evaluating conditions relevant to various applications is part of our DNA as operator of the largest Simmering testing facility world-wide. With extensive in-house knowledge, we specialize in assessing application-relevant conditions across all stages of the hydrogen value chain. Our expertise covers everything from production and processing to distribution and storage all the way to utilization, ensuring that materials and components meet stringent standards for performance and safety.

Our company excels in testing static seals to determine leakage under relevant operational conditions, ensuring reliability and safety. We specialize in accelerated aging of materials in application-relevant media, spanning a wide temperature and pressure range. Additionally, we determine empirical parameters for our materials in-house, providing accurate data to feed simulation models. All these services are delivered seamlessly, offering comprehensive solutions from a single source.

On top of that, we are continuously expanding our testing capabilities to stay at the forefront of innovation, enabling us to provide comprehensive solutions tailored to the evolving needs of the hydrogen industry. This commitment to excellence ensures reliable and efficient performance in all hydrogen applications.

Join Us!

Experience Freudenberg Sealing Technologies, its products and service offerings in text and videos, network with colleagues and stakeholders, and make valuable business contacts.

Connect on LinkedIn! open_in_new