Railway

Railway Air Brake Seals - Setting the Course for the Future

Sealing Solutions for Railway

When it comes to sustainable mobility, railways are already moving ahead today. In local transport, the course is set for automation and driverless automatic operation. Effective risk minimization during operation requires a high degree of functional safety. The chassis with its assemblies is playing a supporting role in the double sense of the word. Seals from Freudenberg Sealing Technologies are rarely visible here, and yet are indispensable.

A look into the future: With high-performance batteries and fuel cells from Freudenberg and combinations of both, rail vehicles are on the right track – especially on non-electrified (secondary) routes and in shunting traffic. With a unique depth of added value, we offer trains complete electromobility packages from a single source: from the separator and the cell to the complete battery solution; from the membrane to the stack to the complete fuel cell system.

Quality Creates Safety

Reliability plays a key role in braking – whether in trams or high-speed trains; in the freezing cold of northern Norway or in tropical, sultry latitudes. Seals from Freudenberg Sealing Technologies ensure consistently high braking force and are known for their functional reliability and durability under all climatic conditions. This is based on the unique materials expertise we have acquired over decades. The result is materials that are individually tailored to the intended application and work reliably in braking systems and their auxiliaries all over the world.

Efficiency Reduces Costs

Rail travelers will appreciate the many ways in which Freudenberg seals improve ride comfort in trains. Train operators also pay attention to economic data and facts. Maintenance is a relevant factor here. The longer the maintenance intervals, the lower the costs.

Freudenberg Sealing Technologies scores points in terms of economic efficiency by offering quality and durability. Using modern calculation methods such as FEM, an extensive materials database and material models, Freudenberg experts are able to simulate the behavior of sealing materials. The holistic innovation process – in close cooperation with the customer – provides valuable insights for both material selection and component design. Rounded off by modern testing methods, this ensures efficiency and quality from the first prototype to the final component.

Discover the new Technical Manual

Become a sealing expert! Our new edition offers an in-depth guide to materials and product expertise, offering a holistic view of sealing technology.

Read now!Discover More on Sealing Solutions for Railway

Low Temperature Diaphragms

The safety-critical heart of every compressed air brake is the diaphragm in the brake cylinder. Specially developed elastomers retain their elasticity even under extremely frosty temperature conditions and ensure consistently high braking force. Their fiber-reinforced structure permanently protects the special diaphragms against fractures and cracks.

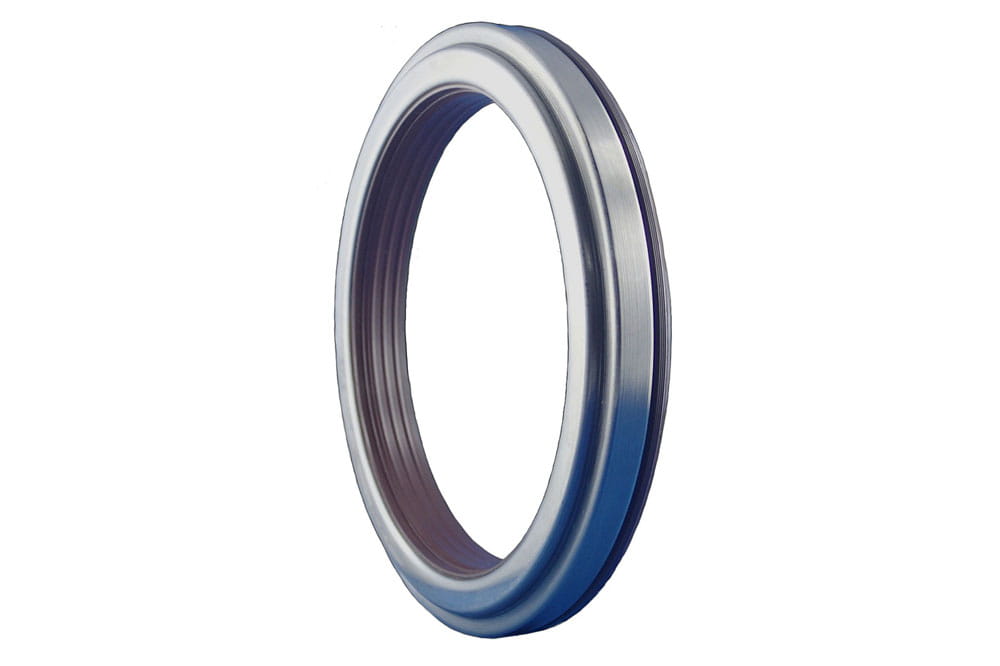

Low Friction TBU Bearing Cassette Seals

Highly robust cassette seals offer bearings the ultimate protection against dirt: in a wide temperature range, with high chemical resistance to greases, oils and additives of high-performance lubricants. Functionality is complemented by efficiency: Low-friction variants improve the CO2 balance, protect against wear and extend maintenance intervals.

High-Precision Valve Components

When tasks are particularly important and standard molded parts are not sufficient, elastomer composite parts come into play – compounds of high-performance elastomers and high-quality metals or plastics. With narrow dimensional tolerances, maximum dimensional accuracy and surface quality, they embody exceptionally filigree precision work so that trains come to a standstill on the shortest possible path when braking.

Join Us!

Experience Freudenberg Sealing Technologies, its products and service offerings in text and videos, network with colleagues and stakeholders, and make valuable business contacts.

Connect on LinkedIn! open_in_new