Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

6-Axis

6-Axis Robot: The Highest Precision and Speed

Sealing Solutions for Six-Axis Robots

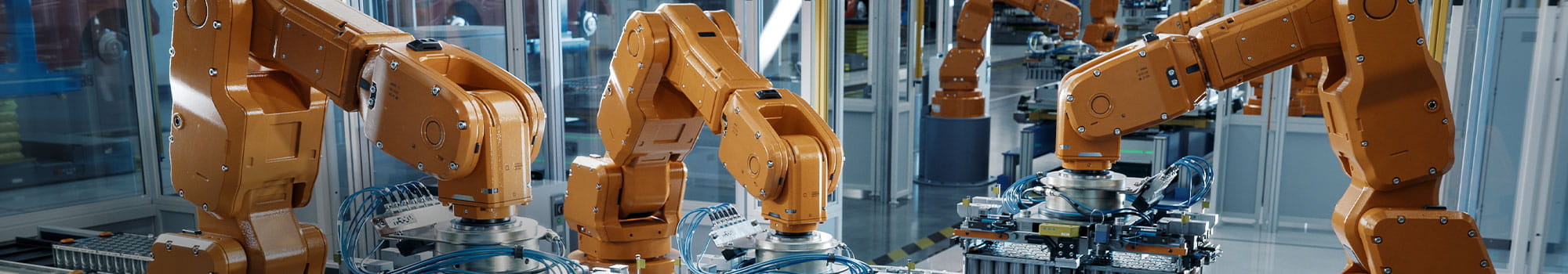

Modern manufacturing processes rely heavily on versatile 6-axis robots. These robots are the backbone of automation in numerous industrial processes. With their exceptional properties, such as high precision, repeatability, and speed, along with the ability to cover large work areas (depending on the design), it's no surprise that 6-axis robots are used extensively across a wide range of industries. These industries include demanding applications in automotive, electronics manufacturing, food and beverage, and pharmaceuticals. For the long-term functional reliability of robotics and automation solutions, it is essential to have top-quality seals that prevent leaks and production line stoppages. With high-performance seals from Freudenberg Sealing Technologies, you can enjoy a longer service life, lower maintenance costs, and improved performance.

High-Performance Seals for Robotics Applications

High reliability and long service life – these are the main requirements for seals used in robotics applications. They are intended to increase efficiency and contribute to occupational safety. At the same time, current market and product trends are increasingly creating further challenges for robotic seals:

- Smaller installation spaces and less weight due to the trend towards smaller robots

- Conformity to current and future industry-specific specifications for sealing materials (the food and beverage industry, the pharmaceutical industry, medical technology)

- Resistance to aggressive media (CIP/Cleaning-in-Place)

- Lower friction to save energy

- Less wear for a longer service life

- User-friendly design for RSS assembly in production

- More innovative seals for faster maintenance processes

High-Performance Materials for 6-Axis Robots

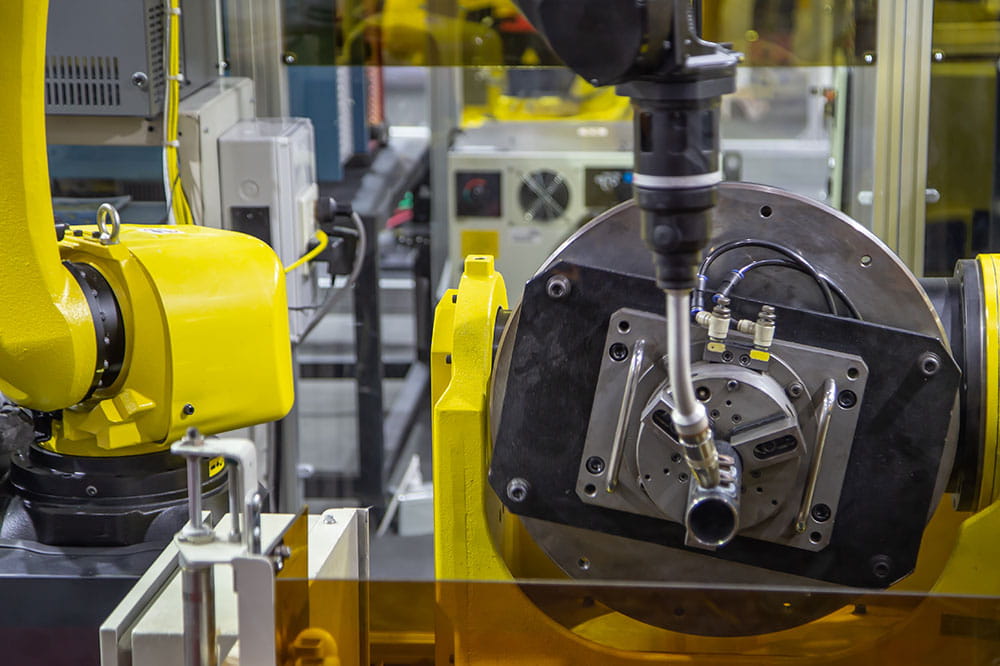

Selecting the appropriate material is critical to ensure the reliability and durability of seals for robotics applications. With the diverse range of applications for 6-axis robots across various industries, which have highly varied environmental conditions and requirement profiles, the seals must meet the most stringent demands. In the construction industry, for example, dust and dirt are commonplace. In foundries, high temperatures pose another challenge. For six-arm robots in washing cabins, they must withstand significant amounts of water, acids, and alkalis during high-pressure cleaning. Conversely, sectors such as chemicals, pharmaceuticals, medical technology, and food and beverage demand impeccable hygiene and cleanliness in all process stages. Furthermore, there are numerous industry-specific standards and certifications that must be met, such as those of the North American Food and Drug Administration (FDA).

Depending on the application, materials for robot seals must meet the following requirements:

- Chemical resistance to lubricants, cleaning agents, hydraulic fluids and other chemicals

- Temperature resistance in different operating temperatures

- Resistance to abrasion and wear

- High aging resistance and a long service life

Learn More About Materials

Our materials are characterized by properties such as smart/pressure-sensitive skin and high performance.

Sealing Challenges for 6-Axis Robots

The 6-axis serial kinematic robot is the most common type of robot today. It is in use around the clock and welds, glues, assembles, packs or palletizes reliably and precisely and with the lowest possible downtime. To ensure this, Freudenberg Sealing Technologies offers comprehensive services for robotics applications in addition to high-performance sealing solutions and high-quality sealing materials:

News & Stories on Robotics

Join Us!

Experience Freudenberg Sealing Technologies, its products and service offerings in text and videos, network with colleagues and stakeholders, and make valuable business contacts.

Connect on LinkedIn! open_in_new