Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

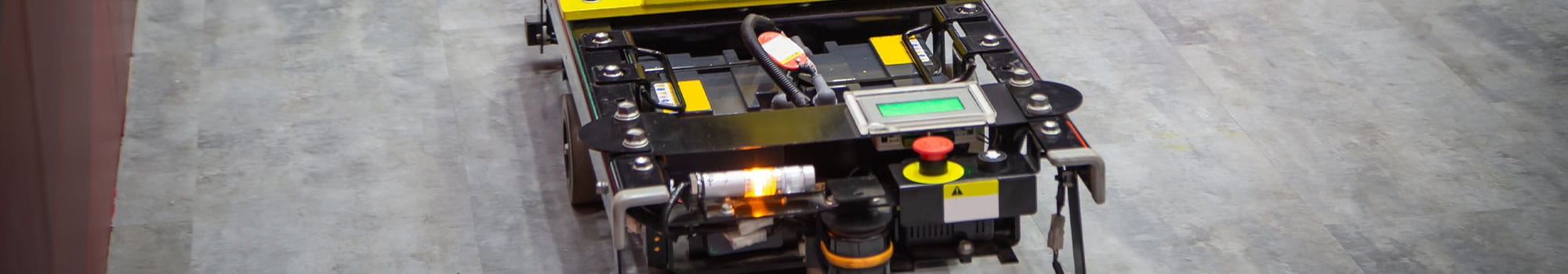

AGVs

AGVs – Automated Helpers in Networked Logistics and Manufacturing Processes

Sealing Solutions for Automated Guided Vehicles

AGVs (Automated Guided Vehicles) have become essential in the core of contemporary logistics and manufacturing. These intelligent, self-driving vehicles are transforming the transportation of materials and products across various industries. From simple tasks like moving goods in warehouses to complex operations in manufacturing automation, AGVs offer a flexible, efficient, and cost-effective robotic solution. Their advanced navigation technology and seamless integration with existing systems makes them a vital component of modern business operations. Our high-quality seals contribute to the efficient and reliable utilization of AGVs, playing a critical role, albeit often unseen, in an automated and connected future.

During cleaning in place (CIP) and sterilization in place (SIP), seals in the food and beverage industry need to be able to withstand increasingly aggressive cleaning media at high temperatures. Aggressive media such as solvent-based coatings also pose enormous challenges for sealing technology in paint shops. Freudenberg Sealing Technologies meets them with high-tech materials such as the chemically highly resistant perfluoro rubber Simriz® (FFKM) developed and manufactured in-house.

High Demands on AGVs Used in Industry

At Freudenberg Sealing Technologies, we comprehend the unique challenges confronting AGVs within modern industry. Our specialized sealing solutions are meticulously engineered to enhance the efficiency and dependability of Automated Guided Vehicles. Our seals designed for AGVs boast the following key features:

-

Abrasion resistance

AGVs often function in demanding industrial settings, necessitating seals with high abrasion resistance. Our seals ensure optimal performance and durability, even under the harshest conditions. -

Chemical resistance

Specially formulated seals for chemical resistance in AGVs offer protection when in contact with lubricants, cleaning agents or other industrial chemicals. -

Temperature and pressure resistance

Our AGV sealing solutions can withstand extreme temperatures and high pressures. They are designed to work effectively in a wide range of operating environments, guaranteeing effective operation in diverse environments, from freezing cold to extreme heat. -

Durability and Low Maintenance

Engineered for longevity and minimal maintenance, our robotic seals for AGVs not only deliver efficiency but also reduce downtimes and overall operating costs.

High-Performance Materials for Automated Guided Vehicles

The selection of the right materials plays a critical role in ensuring the efficiency and durability of seals in AGVs (Automated Guided Vehicles). These self-propelled robots operate across a spectrum of industrial and commercial settings, subjecting them to a myriad of stresses ranging from mechanical abrasion and chemical exposures to extreme temperature fluctuations.

In warehouses and production facilities, AGVs contend with challenges such as dust, dirt, and mechanical wear. Conversely, in sensitive sectors like the food and pharmaceutical industries, maintaining hygiene and preventing contamination are paramount. The seals chosen must not only endure these demanding operational conditions but also contribute to the seamless and safe operation of AGVs, reducing downtime and maximizing overall operational efficiency.

Materials for AGV seals must adhere to specific criteria based on their intended applications:

-

Chemical Resistance

Ensuring resilience against lubricants, cleaning agents, and diverse industrial chemicals. -

Temperature Resilience

Capable of withstanding extreme temperature variations. -

Abrasion and Wear Resistance

Ability to withstand mechanical abrasion and wear in operational environments. -

High Ageing Resistance and Long Service Life

Maintaining durability and longevity under prolonged usage.

Moreover, these seals often necessitate compliance with industry-specific standards and certifications, such as FDA conformity in the food and pharmaceutical sectors. Adhering to these requirements assures the efficient and safe functioning of AGVs across a wide spectrum of operating conditions.

Learn More About Materials

Our materials are characterized by properties such as high performance.

Services for Greater Efficiency of Your AGV Fleet

Automated Guided Vehicles (AGVs) have become indispensable within modern logistics and production operations. They excel in transporting goods, autonomously navigating complex environments, and executing various tasks such as material handling and order picking. All these functions are aimed at optimizing efficiency and reducing downtime.

To meet the rigorous performance demands of AGVs, Freudenberg Sealing Technologies not only offers advanced sealing solutions and high-quality materials but also provides a comprehensive range of services.

News & Stories on Robotics

Join Us!

Experience Freudenberg Sealing Technologies, its products and service offerings in text and videos, network with colleagues and stakeholders, and make valuable business contacts.

Connect on LinkedIn! open_in_new