Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

Cobots

Cobots – Man and Machine Working Hand-In-Hand

Indoor & Outdoor Automation With Collaborative Robots

Cobots, short for collaborative robots, have become a fundamental aspect of modern industry, marking a new era in industrial automation. Unlike other robot types, they can operate near humans without posing risks. Advanced sensor technology and sophisticated algorithms enable them to detect human presence, ensuring a safe working environment.

Due to their high flexibility and user-friendliness, these machine helpers play a key role in streamlining automation tasks across diverse industries, ranging from automotive production to small-batch manufacturing. With quick setup and intuitive controls, they also pave the way for automated production in small and medium-sized enterprises (SMEs).

Sealing Solutions for Demanding Cobot Applications

The high flexibility of cobots, not only in adapting to changing tasks but especially in diverse working environments, places stringent demands on the seals employed. To guarantee operational reliability and long-term durability, it is crucial to protect the joints from dust, splash water, and other contaminants. Seals play a pivotal role in this context. Freudenberg Sealing Technologies' high-performance sealing solutions not only prevent leaks and potential failures but also enhance the efficiency of robotics applications by ensuring a long service life.

High-Performance Materials for Cobots

Sealing materials in cobots must meet various challenges and requirements to ensure optimal performance and offer a long service life. Some of the key material challenges for seals in cobots are:

- Wear resistance

Materials must exhibit high wear resistance to endure the extended operational time and constant mechanical stress experienced by cobots.Flexibility: Seals should be flexible enough to accommodate movement and deformation without cracking or breaking. - Temperature resistance

Materials need to withstand both high and low operating temperatures, especially in extreme environmental conditions. - Chemical resistance

Sealing materials must resist exposure to various chemicals such as cleaning agents, lubricants, or process media, depending on the specific application. - Low friction

To ensure smooth cobot movement and minimize energy consumption, seals should utilize materials with a low coefficient of friction. - Rapid recovery

Seals need to quickly return to their original shape after deformation to maintain consistent sealing performance. - Resistance to environmental influences

UV, ozone, and weather resistance are essential if cobots are used in exposed or variable environments. - Long-term aging resistance

Materials should exhibit long-term aging resistance to ensure the seal remains effective throughout the cobot's lifespan. - High sealing efficiency

Above all, sealing materials must provide effective seals to prevent the ingress of dirt, dust, and other contaminants.

The careful selection of sealing materials plays a pivotal role in influencing the efficiency, longevity, and reliability of cobots. Therefore, the critical importance of meticulous material selection, coupled with regular maintenance and inspections, cannot be overstated.

Learn More About Materials

Our materials are characterized by properties such as smart/pressure-sensitive skin and high performance.

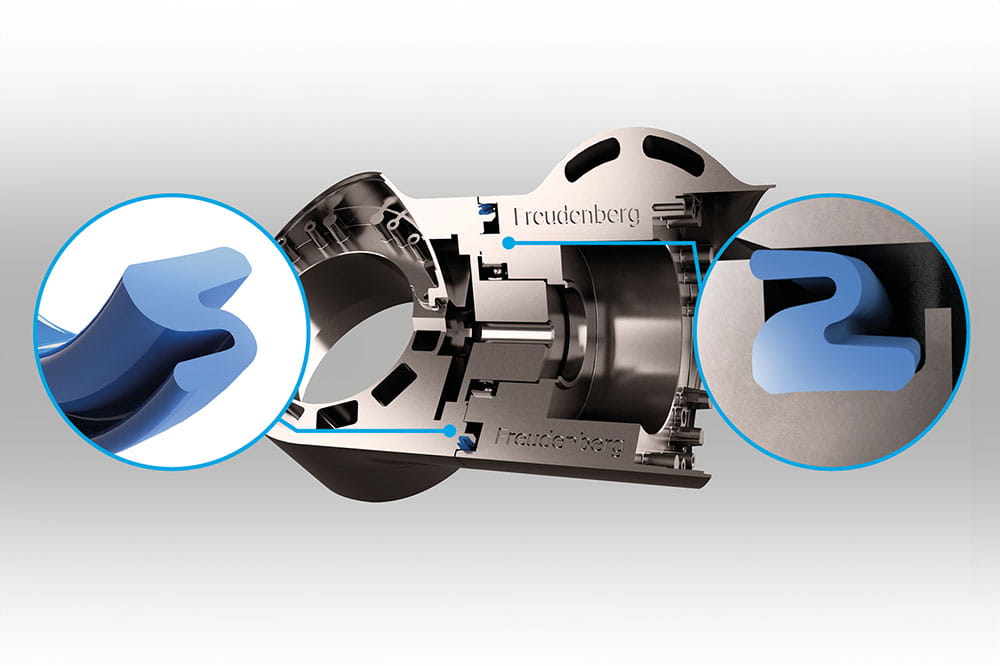

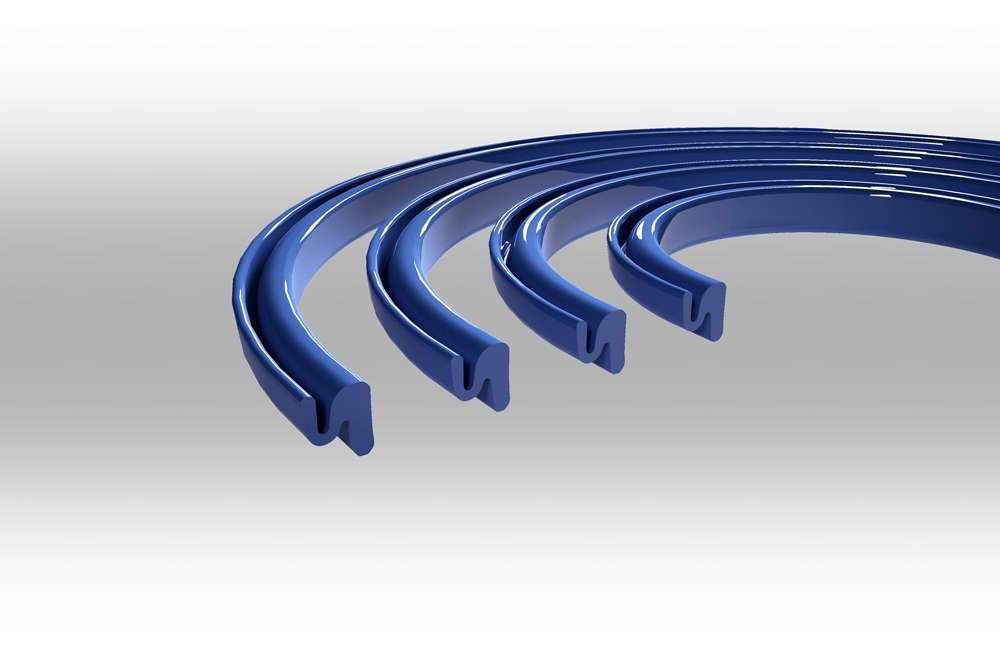

Ingress Protection Seals for Cobots (IPSR)

Collaborative robots are increasingly being used in difficult industrial environments or outdoors where water ingress can take place. In particular, outdoor use is a trend that will continue in the future. Freudenberg Sealing Technologies has developed Ingress Protection Seals for Robots (IPSR) to ensure that AGVs, collaborative robots and humanoid robots’ function reliably under extreme conditions. These seals for demanding robotic applications offer excellent protection against harmful environmental influences with low friction. High-quality, wear-resistant materials and the special surface design ensure a long service life even under poor lubrication conditions.

Safely working outdoors

The challenges in the development of ingress protection (IP) seals for robot arms are diverse: robot arms consist of numerous joints that enable movements in different directions. Within these joints, there is only a very small installation space for the seal, which must be able to compensate for the tangential and axial displacements that occur there. A classic O-ring cannot do this. The sealing lip of the IPSR is designed in such a way that it can optimally adapt to these movements.

Thanks to the IP seals from Freudenberg Sealing Technologies, cobots are therefore optimally protected against harmful environmental influences such as dust and water ingress. Depending on the installation space, surfaces and tolerances, certification up to protection class IP65 can be achieved.

Ingress Protection Ratings(IP Codes)

The degrees of protection (IP codes) are defined by the international standard IEC 60529. The IP ratings consists of two digits:

First rating: Protection against foreign objects and contact

| Rating | Protection Class | Description |

| 0 | No protection | No special protection |

| 1 | Protection against large foreign objects | Protection against the penetration of solid foreign bodies with a diameter greater than 50 mm, such as the palm of a hand |

| 2 | Protection against medium-sized foreign bodies | Protection against the penetration of solid foreign bodies with a diameter greater than 12.5 mm, e.g. a finger |

| 3 | Protection against small foreign bodies | Protection against the penetration of solid foreign bodies with a diameter greater than 2.5 mm, such as tools |

| 4 | Protection against very small foreign objects | Protection against the ingress of solid foreign bodies with a diameter greater than 1 mm, such as fine wires |

| 5 | Dust protection | Ingress of dust in harmful quantities is prevented, but not completely; complete protection against contact |

| 6 | Dust-tight | No ingress of dust; complete protection against contact |

Second rating: Protection against water

| Rating | Protection Class | Description |

| 0 | No protection | No special protection |

| 1 | Protection against dripping water | Protection against vertically falling drops, does not cause any harmful effects |

| 2 | Protection against dripping water when tilted (15°) | Protection against vertically falling drops when the housing is tilted up to 15° |

| 3 | Protection against water spray | Protection against water sprayed up to 60° from the vertical |

| 4 | Protection against splashing water | Protection against water splashing against the housing from any direction |

| 5 | Protection against water jets | Protection against water jets from a nozzle (from any direction) |

| 6 | Protection against strong water jets | Protection against strong water jets and water waves |

| 7 | Protection against temporary submersion | Protection against water when temporarily submerged at a certain depth |

| 8 | Protection against permanent submersion | Protection against water during permanent immersion under specified conditions |

Well Protected With Low Friction

Cobots and humanoid robots work closely with humans without a protective space. To ensure that this is always safe, the robots must stop in good time as soon as they come into contact with a human. Measuring devices built into the robot arm ensure that an emergency stop is triggered as soon as a defined collision force occurs. However, if seals with too much friction are installed in the robot arm, this can become problematic. The high friction means that a safety stop is only triggered at a significantly higher force and therefore much too late. This can be dangerous! The sealing specialists at Freudenberg have therefore developed a special sealing geometry and combined it with low-friction, wear-resistant materials. The result is a reliable IP solution with low and constant friction without stick-slip effect, which safely achieves the required friction torque values.

The added value for your cobot applications:

Our IP seals offer superior performance thanks to the low-friction design and special surface in combination with our high-performance materials:

-

Protection against harmful environmental influences to fulfill IP class requirements

-

Low and constant friction without stick-slip effect to achieve the required friction torque values

-

Long service life even under poor lubrication conditions

-

Extremely flexible dynamic lip without spring, which compensates for large installation space tolerances

-

Firm static fit in the groove, which prevents relative movements

-

Good dissipation of frictional heat

-

Simple assembly

Maximum Cobot Performance, Minimum Risk

At the core of modern industry are cobots that seamlessly and safely interact with humans. Their reliable and error-free operation is not only critical for productivity but also for ensuring workplace safety. Any malfunction or downtime can lead to production delays and potential safety risks for employees. Freudenberg Sealing Technologies ensures the efficient and safe operation of cobots through its world-class sealing solutions and comprehensive services. Our services provide added value that extends beyond the product itself, supporting the seamless operation of cobots in any industry.

News & Stories on Robotics

Join Us!

Experience Freudenberg Sealing Technologies, its products and service offerings in text and videos, network with colleagues and stakeholders, and make valuable business contacts.

Connect on LinkedIn! open_in_new