Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

EPDM

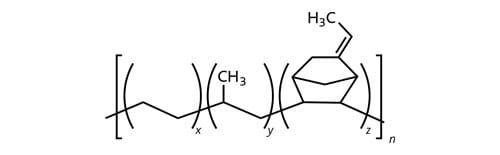

EPDM – Ethylene Propylene Diene Rubber Monomer

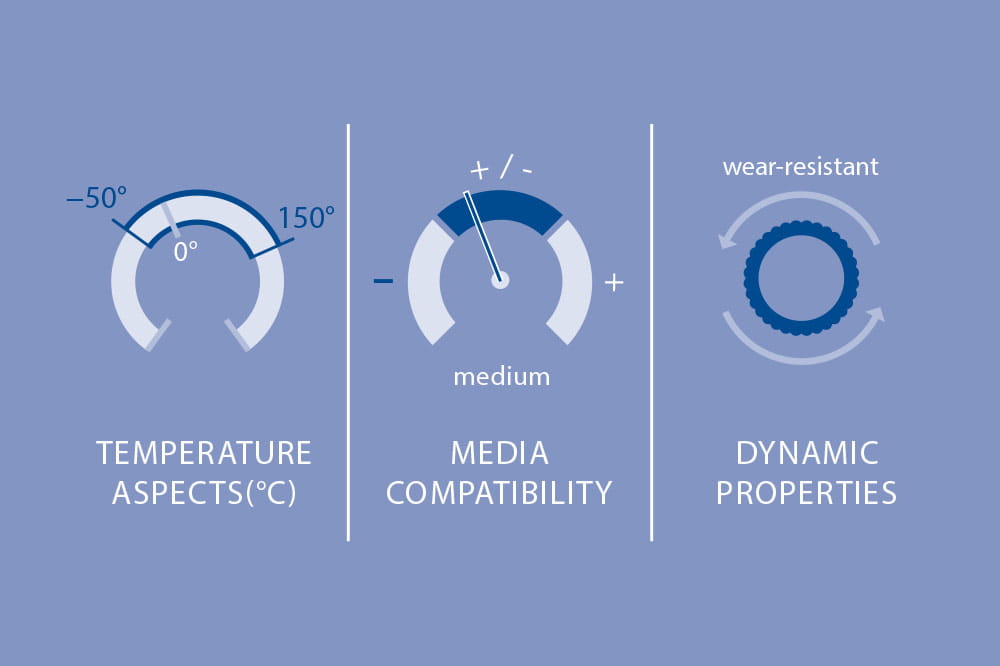

EPDM enjoys high acceptance in the food and pharmaceutical industries. Freudenberg Sealing Technologies has numerous approvals for this material¹. EPDM is indispensable for CIP (clean in place) or SIP (sterilization in place) cleaning processes. However, the fat content of the media may not exceed certain limits. EPDM is a polymerization made of ethylene, propylene and a diene monomer².

It displays high media resistance to brake fluids, acids and lyes, the flame-resistant hydraulic fluids HFC and HFD, hot water and steam. But it is not stable in petroleum-based oils and fats or in gasoline and hydrocarbons. In turn, this material is inexpensive and can be used almost universally – although not with oils.

The special material variations EPDM 291 (black) and EPDM 253815 (white) were developed for the process industry. All exhibit excellent resistance in CIP/SIP media. Freudenberg Sealing Technologies’s white EPDM 25813 is superbly suited to the pharmaceutical industry due to its lack of softening agents, which validates an appropriate extractables benchmark. But the fat content of the media must not exceed certain limits. EPDM also pushes against its limits in contact with flavors. In these cases, the universal material Fluoroprene® XP is the preferred solution for the process industry.

¹ For example, FDA 21 CFR 177.2600, 3-A Sanitary Standards Class II, EG (Reg.) 1935/2004, USP Ch. 87 and Ch. 88 – Class VI, ADI-free

² Dienes are organic compounds that contain two carbon-carbon double bonds, such as dicyclopentadiene

Discover the new Technical Manual

Become a sealing expert! Our new edition offers an in-depth guide to materials and product expertise, offering a holistic view of sealing technology.

Read now!

Join Us!

Experience Freudenberg Sealing Technologies, its products and service offerings in text and videos, network with colleagues and stakeholders, and make valuable business contacts.

Connect on LinkedIn! open_in_new