Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

04.08.2016

Coveted Certification Earned in China - Changchun Facility Passes ISO/TS 16949 Audit

But automakers not only require their suppliers to set up a production facility in the country – they must guarantee globally valid quality levels as well. That is why the ISO/TS 16949 certification, which has been implemented across Europe, is also required in China.

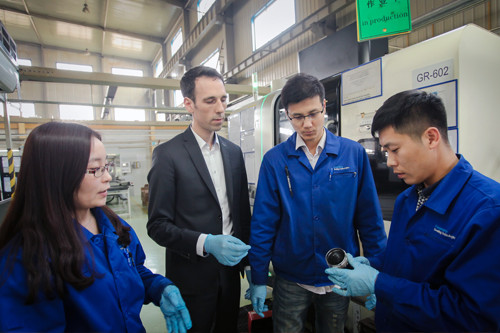

With this in mind, the starting shot was fired in late 2014 for a project that launched the so-called “Corporate Scheme” – a globally valid quality management system – in China. The project team included Ralph Schmidt, Vice President, Corporate Quality Management Europe; Klaus Guntermann, former Quality Manager and now BU Manager in the Lead Center Accumulator in Remagen; Gregory Dauteuil, Changchun General Manager; and Wang Hang, former Quality Manager and current Sales Manager.

Schmidt visited the Changchun plant in the spring of 2015. “For us, it was important to train the people and explain the system,” he said. The Chinese employees then carried out everything that was required.

In September, an internal pre-audit initially took place in Changchun. “It was like a dress rehearsal for all of us,” Schmidt said. By November, the effort reached this point: Working with DQS, Freudenberg’s global certification partner, the facility was closely scrutinized and then certified. “All in all, we did very well. The auditor praised the employees in Changchun because they accomplished a great deal in a short time,” Schmidt said. After remedying some fairly small deviations, Changchun received the coveted certificate in January.

“The ‘corporate scheme’ offers us many advantages,” he said. They relate to a uniform system that requires the same procedures, processes and documents worldwide. This specific case involved the transfer of Remagen’s production processes on a one-to-one basis to the accumulator production area in Changchun. “The auditing expense is also greatly reduced due to our global foundation and standards.” The audit management and planning with DQS were handled centrally. “The approach yielded additional savings in time and money. Similarly, it relieved the facilities of administrative expenses,” said Karl-Heinz Westhoff, Senior Vice President, Corporate Quality. In concrete terms, the man-days that FST required fell forty percent. That worked out to savings in the tens of thousands of euros – a considerable sum.

Further Articles With These Taggings

First Hand News

Best of all, keep up with the latest developments

with the Freudenberg Sealing Technologies newsletter.