Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

21.03.2016

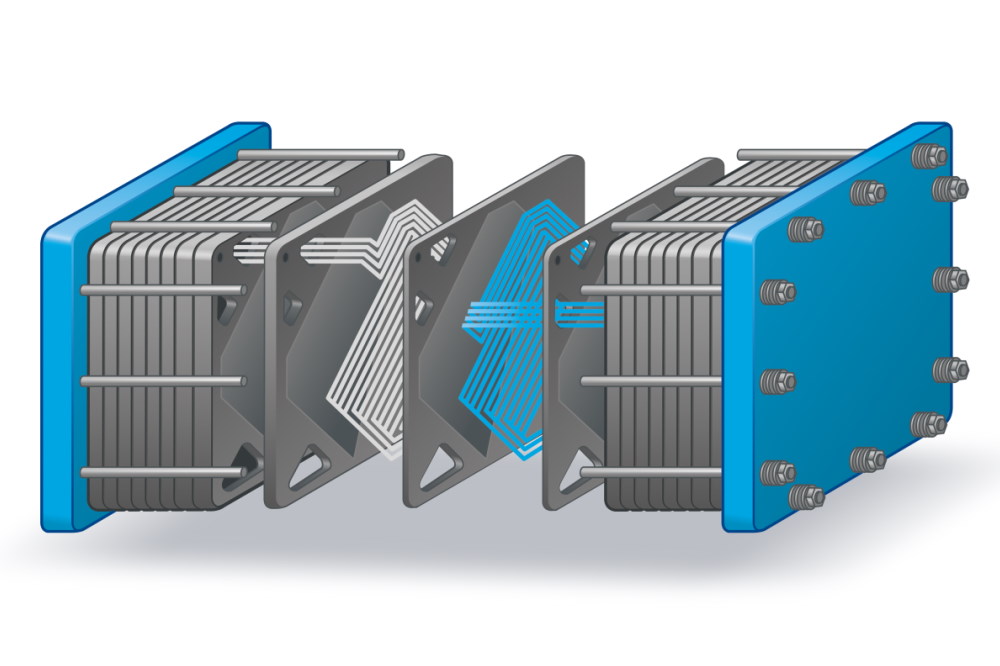

One tool – Three butterfly valve seals

A tool concept that saves hard cash: As a formed part, a butterfly valve seal unfortunately requires the manufacture of a customer-specific tool. To minimize the cost to you, Freudenberg is now offering a tool concept that works with all three seal materials. Just one tool instead of three is required when butterfly valve seals made of several materials are in demand – which is often the case.

Together, EPDM, HNBR and Fluoroprene® XP are the perfect trio for the food and pharmaceutical industries. While EPDM is superbly suited for aqueous systems, HNBR offers outstanding values for wear and stability. Fluoroprene® XP is used if the media resistance of EPDM and HNBR falls short. Fluoroprene® XP is the best choice for contact with flavorings as well as polar, nonpolar and aggressive media.

The three material variants together cover all conceivable requirements in the processing industry. The joint use of single tool concept for all three helps to reduce your purchasing costs.

Further Articles With These Taggings

First Hand News

Best of all, keep up with the latest developments

with the Freudenberg Sealing Technologies newsletter.