Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

02.08.2016 | News

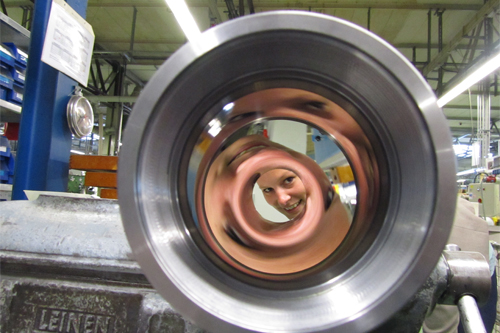

Close to the Customer - Piston Accumulators from Europe for Industrial Applications

REMAGEN. By building a new manufacturing operation for piston accumulators for industrial applications in Remagen, Freudenberg Sealing Technologies (FST) has expanded the opportunities that it initially opened up by acquiring Tobul Accumulator Inc. at Bamberg in the U.S. in mid-2014.

First, some background: Nearly two years ago, FST acquired Tobul, a specialist in large piston and bladder- type accumulators. The Lead Center (LC) Accumulator has primarily used it to pursue three goals: first of all, to round out its range of products and offer customers a complete lineup of hydraulic accumulators – piston, diaphragm and bladder-type accumulators in a range of volumes for all appropriate requirements and applications; second, since it had been focusing on Europe, to position its business more globally; third, to develop other market segments in general industry.

In the U.S., the Lead Center focused its main attention on projects with large piston accumulators as well as bladder-type accumulators for industrial applications and large volumes that often exceed ten liters. The emphasis in America was on a number of market segments: energy, oil and gas, mining, and fluid power. Hydraulic accumulators for blowout preventers are a very important product; they prevent the uncontrolled escape of drilling fluid, petroleum or natural gas in raw material extraction. Large steel presses for heavy industry are another typical application.

At the push of a button, large piston accumulators even get roller coasters moving.

In Europe, FST concentrates on the series production of small accumulators up to 3.5 liters in volume. The diaphragm accumulators produced in Remagen are primarily used in the automotive industry as well as in construction and agricultural machinery, and, to some extent, in wind power facilities. In addition, the company manufactures customer-specific products – for example, special piston accumulators in the low-pressure range for cars – with less than one liter of accumulator volume.

“Right from the start, this ideal supplement to our original situation in Europe and the U.S. offered a great deal of potential for cross-selling and new products on both continents,” said Thomas Fröhlich, CC Manager, Accumulators Industry. To be specific: In Remagen, FST has recently added the expertise to manufacture piston accumulators on a major scale for industrial applications. The basic idea is proximity to the customer, meaning the ability to manufacture locally to meet local needs.

Katinka Schablowski, Business Development Manager, Accumulators Europe, cited a few of the advantages: “This is cost-efficient, allows fast response times and makes it possible to dispense with long transportation routes. Unlike many of our competitors, we do not supply systems. Instead, we are an independent provider of accumulators that combines product expertise with market-specific know-how.”

As a first step in the marketing of its new product group, “industrial piston accumulators,” FST is taking advantage of its existing customer contacts at makers of agricultural and construction machinery as well as wind power facilities.

The company’s local production expertise in Remagen also facilitates joint development partnerships with lead centers based in Europe. In one example, great results have been achieved in a project with the Lead Center Fluid Power Industry in Schwalmstadt: an especially efficient oil/gas seal with a long service life for piston accumulators.

CE-Certified

Numerous region-specific guidelines must be observed in the accumulator business, and many certifications are needed as well. Thanks to the new CE certification of the Lead Center Accumulator, FST’s customers are getting large, U.S.-produced piston accumulators quickly and affordably. “Previously, an expensive, individual certification was necessary for every product before its export to Europe,” Fröhlich said. “That’s no longer the case. The comprehensive CE marking is making it much easier for us to establish our U.S.-built accumulators in Europe.”

More news on the subject General

First Hand News

Best of all, keep up with the latest developments

with the Freudenberg Sealing Technologies newsletter.