Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

26.09.2016 | News

Taking the Wind Sector by Storm

Low pressure areas. Cooler temperatures. Stormy winds. Not everyone is immediately thrilled with the arrival of the darker, colder months. But operators of wind power facilities consider high winds to be the proverbial water for the mill. Their huge rotors are powerfully driven. They rotate quickly and vigorously and produce plenty of “clean” energy in an environmentally friendly way.

After an initial hesitation, the economic winds have long shifted in many countries. Renewable energy is on the rise. Wind power has now become the fastest-growing source of renewable energy worldwide. In view of the decline of fossil fuels, every wind turbine stands a monument to sustainable, resource-conserving energy production.

In the fall and winter, extreme weather events are especially pronounced offshore – where more and more turbines are generating electricity from the raw power of nature. Off the coast on the high seas, wind power facilities are exposed to scorching heat and UV radiation in the summer. And now, during autumn, sharp gusts blow around the rotors. The mix of weather, combined with the moist, ozoniferous salt air, poses extreme challenges to all the components in a turbine.

Resisting Adverse Weather

Maximum functional reliability is crucial for long, trouble-free periods of operation and long maintenance intervals – in the harshest elements. That is because maintenance and repairs are especially difficult and expensive offshore. So seals must stand up to all adverse conditions and effectively protect wind turbines.

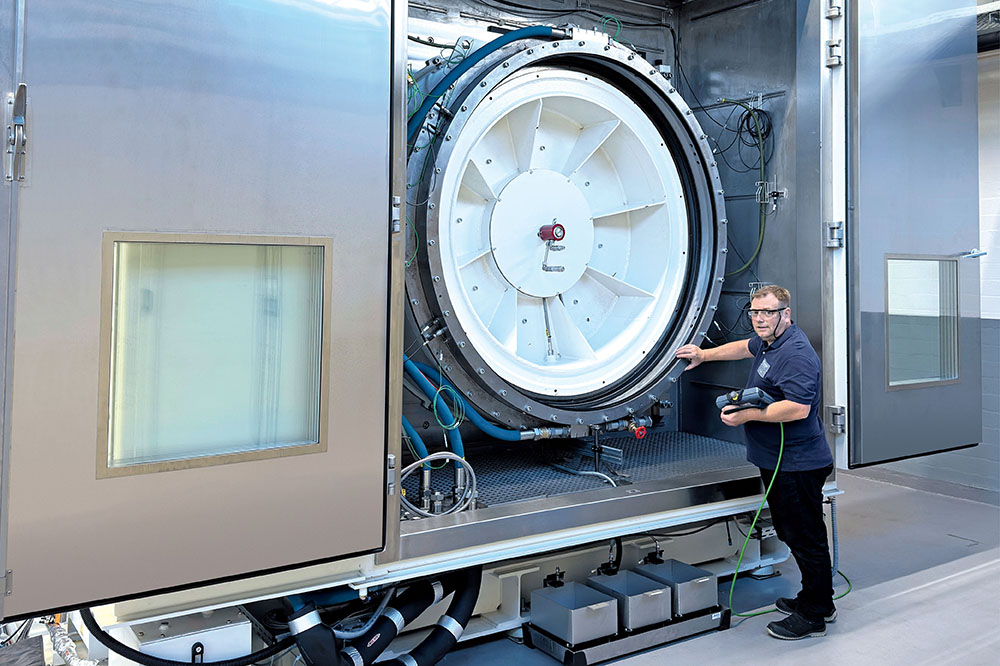

Freudenberg Sealing Technologies (FST) has in-depth material expertise, which is the best possible foundation for these low-friction, robust and especially wear-resistant sealing solutions. The premium materials in the Ventoguard family – which Freudenberg developed – have firmly established themselves in the market as high-performance options. At an early stage, during the development process, computer-supported test processes, which reliably simulate stresses during operation, ensure the dependability of these sealing solutions.

In wind power facilities, FST’s storm-tested sealing solutions are used in blade and yaw bearings as well as main bearings, and as hydraulic seals in pitch cylinders and oil seals in main gearboxes. FST is presenting these sealing solutions as well as its comprehensive portfolio of accumulators, which are certified for the wind power sector in North and South America, Europe and China, at WindEnergy 2016 in Hamburg, September 27-30.

The stand’s highlight is a cutaway prototype of a triple-row ball turning bearing for rotor blade adjusters. In close cooperation with the customer, FST developed a special profile seal that optimally withstands the special pressures in this application, among other benefits. “With this exhibit, we are demonstrating how we use our design and material expertise to develop made-to-order sealing solutions with our customers – and for our customers,” said Michael Littig, Global Segment Director Energy at Freudenberg Sealing Technologies.

More news on the subject Renewable Energies

First Hand News

Best of all, keep up with the latest developments

with the Freudenberg Sealing Technologies newsletter.