Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

01.09.2016 | News

Care-free Vacation Days on the High Seas

Cruise Ships Take Freudenberg Seals Along on Their Voyages

Cruise ships have been riding a wave of success for years. This segment of the travel industry is booming. These floating hotels are offering more and more vacationers a home during the most beautiful time of the year – the summer months that we are enjoying right now.

Luxury liners are promising their guests, who usually number a few thousand, a fascinating holiday from bow to stern: sports and wellness services, casinos, and now even ice rinks or full park facilities. Another trend: While the dream ships were once reserved for the wealthy, shipping companies have been pursuing the middle class with comfortable sea voyages for years. As a result, more new dream ships are being launched for different target groups.

Media reports have regularly covered the huge expenditures for staff and logistics behind the scenes in the cruise business. There are also technical features that keep passengers and crew safe and free from care, but they largely escape the public's gaze. As in many other applications, seals from Freudenberg Sealing Technology take over important tasks on cruise ships. They are often invisible but always essential.

Imagine a cruise ship not being able to head out to sea due to a technical defect. The financial damage would be immense. That is why the highest possible functional reliability and long maintenance intervals are especially a must in the shipping industry.

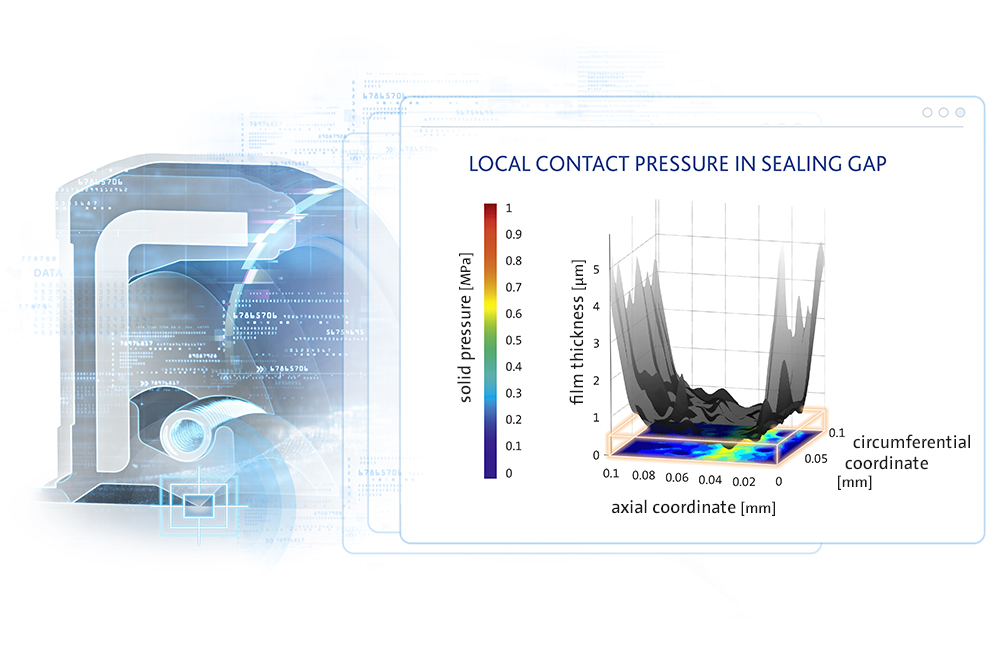

Seals must prevent oil leaks over the long haul: on stormy seas, with constant exposure to salt water and salt air, in arctic cold and tropical heat. Their reliability not only benefits and reassures operators, vacationers and crew. They are vital for marine life. Leakfree seals protect the ocean’s flora and fauna.

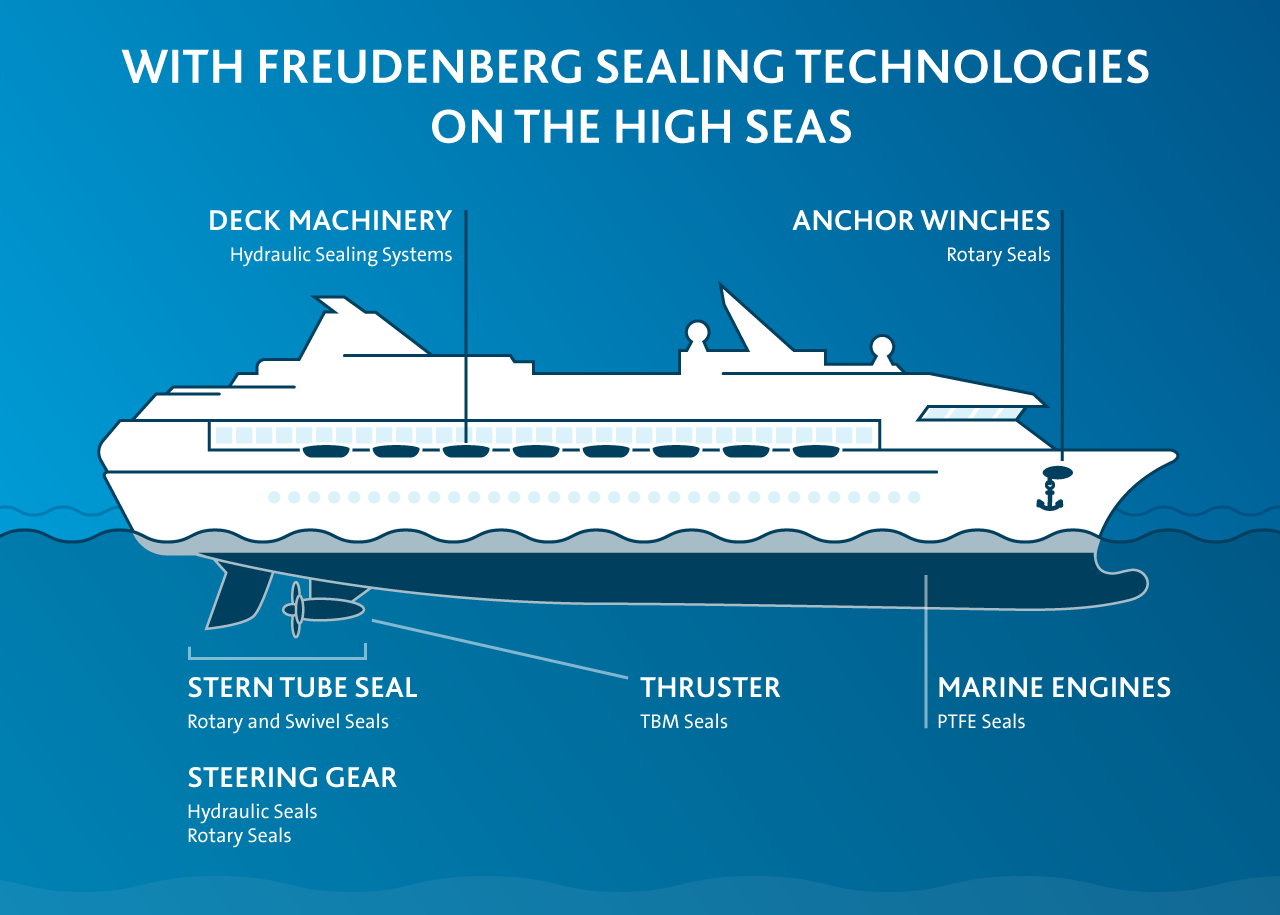

For decades, cruise ships with sealing solutions from Freudenberg Sealing Technologies have moored in ports throughout the world and put out to sea from them. They include PTFE seals in the ship's engine or – further in the direction of the propeller – the sterntube seal. Freudenberg hydraulic seal systems are used on deck or at the rudder. And rotary seals help to put the ship on the right course, just as TBM seals in the thruster improve its maneuvering. And when the cruise ship is moored in a harbor, Freudenberg seals are brought to bear in its winches as well.

More news on the subject Material Expertise

First Hand News

Best of all, keep up with the latest developments

with the Freudenberg Sealing Technologies newsletter.