Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

17.02.2017

Freudenberg Sealing Technologies gives Batteries Air

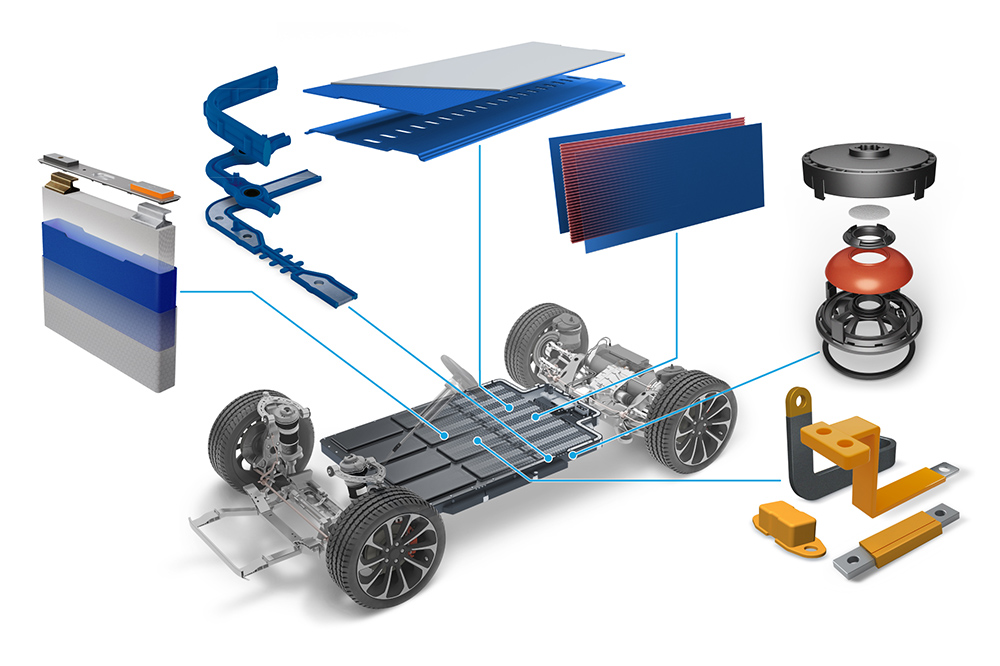

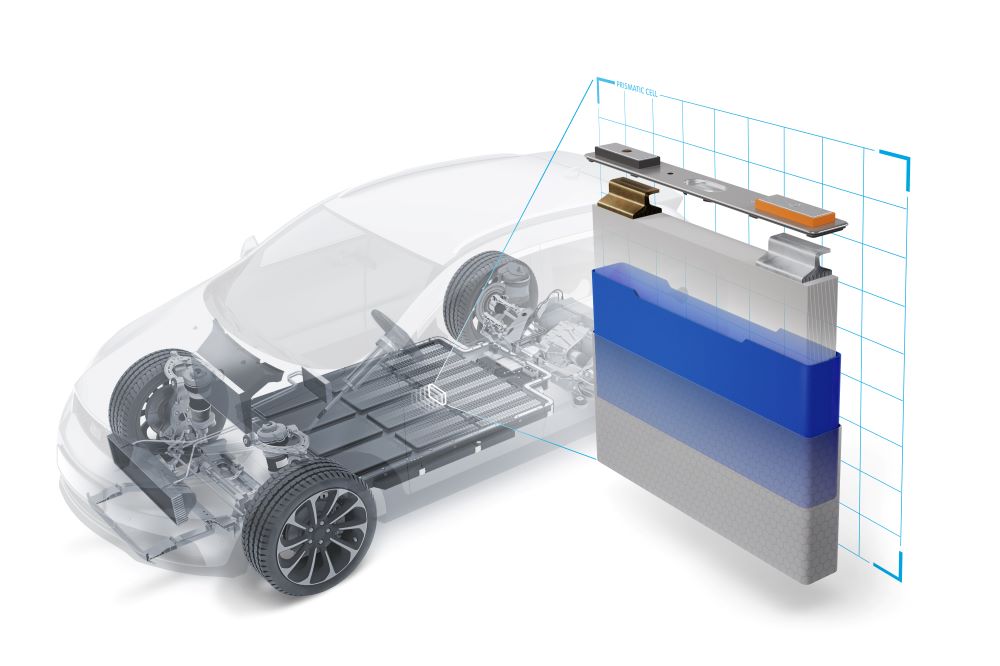

Enormously high-performing – and indeed distant – relatives of the voltaic pile are propelling electric cars today. But the next generation of lithium ion batteries is already in the starting blocks and will be on the road this year. Their advantage: double the energy in the same amount of space. These high-tech batteries can be charged up more quickly and give vehicles greater range. But Dr. Peter Kritzer, Innovation Leader at Freudenberg Sealing Technologies (FST), is also aware of problems associated with them: “If the components of previous battery systems are simply adopted for the new generation of batteries, safety-relevant issues may arise.”

Over the past 50 years, FST has acquired great expertise in the safety and thermal management of batteries. For example, its sealing experts have conceived of a new housing seal that perfectly establishes the crucial pressure equalization needed for electric mobility. Dr. Kritzer presented additional ideas at the 7th European Advanced Automotive Battery Conference (AABC) in Mainz early this year. One example: a special nonwoven fabric that combines the required water impermeability with increased air permeability while offering still more added value as a degassing element. The improved ventilation prevents battery heating. With this and other concepts, he struck a nerve with representatives of the auto industry. The presentation showed that FST has identified an industry need early and can be a valuable development partner. FST recently bundled its electric mobility know-how in a newly formed organizational unit. “Our general approach is to think a step ahead with our customers,” Kritzer said. “We have a great many ideas in reserve and many of them are already patented.” In this way, Freudenberg can team up with automakers to develop complete modules and systems. “We see ourselves as a partner in cooling and safety,” Kritzer stressed.

Further Articles With These Taggings

First Hand News

Best of all, keep up with the latest developments

with the Freudenberg Sealing Technologies newsletter.