Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

05.09.2017 | Story

Simpler, Faster, Integrated: Sealing Systems for Hydraulic Cylinders

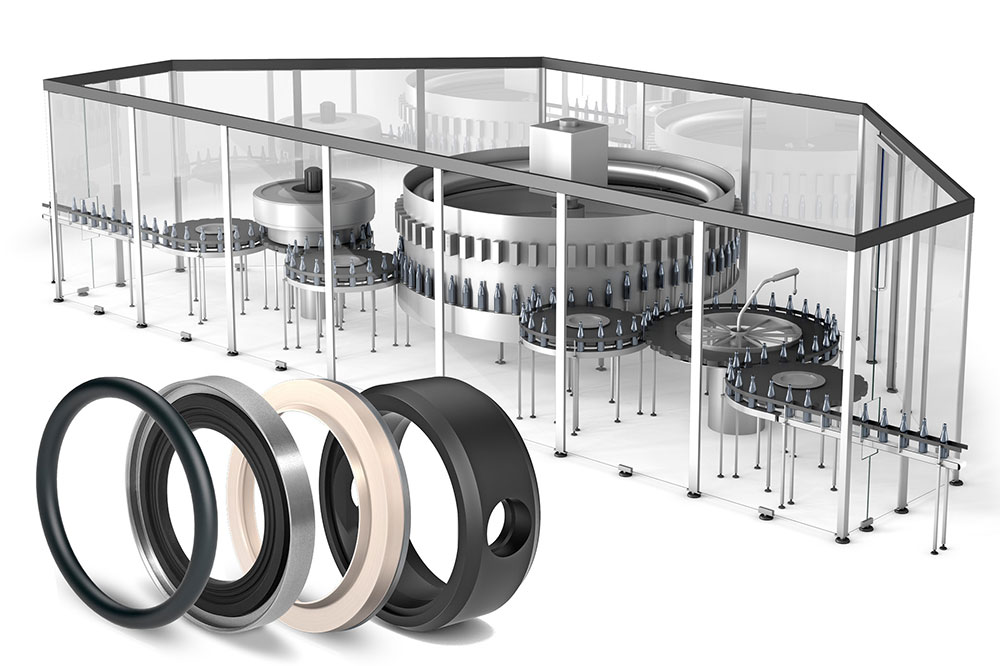

The right mixture does the trick – even for seals used in hydraulic cylinders. But the optimal interplay of the individual seals is a delicate matter. To save its customers a great deal of time and effort, Freudenberg Sealing Technologies (FST) has developed five preassembled sealing systems. They contain all the components needed for specific customer applications.

An Entire Solution in a Single Package

Freudenberg takes the customer out of the complex, tedious process of selection, adjustment and modification, providing integral sealing systems. The company has developed so-called ‘application cards’ that specific dedicated sealing systems for selected market segments and their applications. Here FST has gone beyond what is normal among its competitors. It doesn’t merely provide a fraction of all the components needed for hydraulic cylinders – it delivers all of them, from piston guides and seals, to primary and secondary rod seals, all the way to rod guides and wipers – and considers all their interactions in the process. As a result, a specialized knowledge of individual sealing elements is no longer needed.

Customer-specific, Controlled Quality

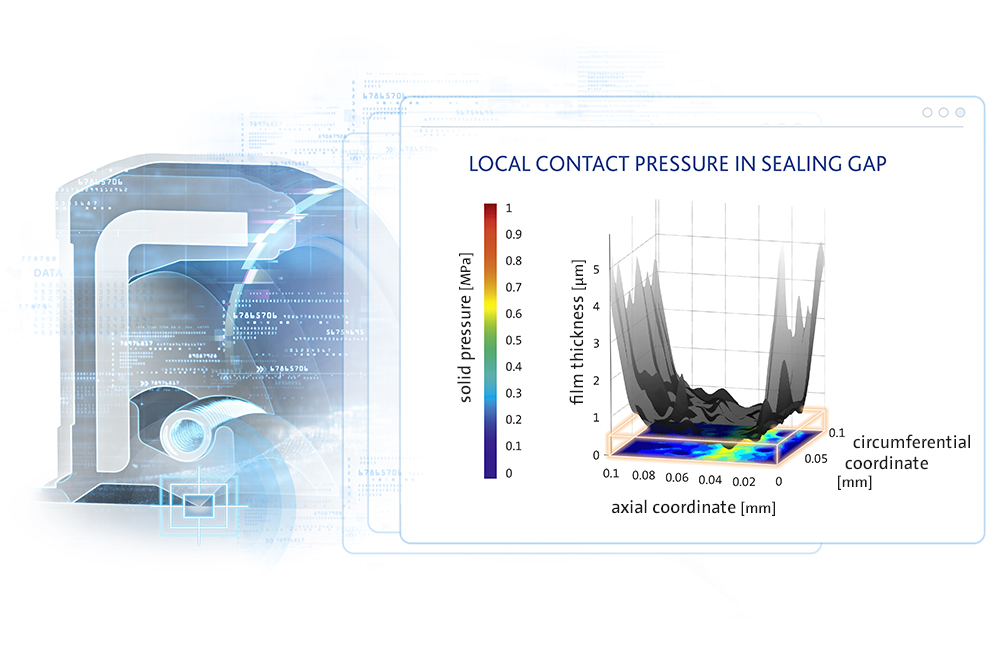

The highlight: Until now, the customer’s analysis was the sole foundation for the sealing system. Now Freudenberg is going a step further and gearing its approach directly to the customer’s specific application and the operating parameters that apply to it. Pressure, temperature, medium, frictional behavior, impermeability and dirt accumulation, along with the expected load, stroke and service life – they are all factors in the selection of the right seals. FST specialists have taken all this into account. The advantage: From the very first stage of development, the customer benefits from Freudenberg’s expertise. And he can draw on solutions whose effectiveness has been reliably confirmed in tests.

Five Concrete Versions of Sealing Systems

1) Very high load-bearing capacity with a long service life: Sealing of the rod shared by primary seal (pressure reduction; very low friction when combined with oil film) and secondary seal (reduces outbound oil film thickness; determines the impermeability of the system); thanks to low pressurization, very favorable friction and wear behavior. Suited for operating pressures up to 400 bar (pressure peaks of 600 bar) and temperatures up to 110°C, with very good media resistance and leak-tightness at the rod. Example of an application: cylinders for heavy construction machinery.

2) High load-bearing capacity with a long service life but reduced pressure: primary and secondary seals at the rod as well, but designed for 320 to 400 bar and 80 or 100°C. Very high impermeability at the rod and very good drift behavior for the piston seal. Example of an application: cylinders for medium-duty construction machinery.

3) High load-bearing capacity with a long service life, optimized for friction: improved frictional behavior due to special materials (less inclination to produce stick-slip effect), simultaneous with good impermeability at the rod. Example of application: suspension and lifting cylinders.

4) For high load-bearing capacity with medium or short service lives: high impermeability thanks to the single rod seal; at the same time, economical due to the lack of the upstream seal. In addition, very good drift behavior due to the piston seal. Example of application: cylinders for truck loading cranes.

5) Economical for low-to-medium load-bearing capacities: very good impermeability and outstanding drift behavior with a single rod seal at 260 to 400 bar and 80 to 100°C. Example of application: cylinders for agricultural equipment or mini-excavators.

Imposing Order on the Sealing Jumble

Sealing systems from Freudenberg Sealing Technologies are integral solutions for hydraulic cylinders. The individual components are adapted to one another and the particular application. Customers benefit doubly: in both design and in the development of the latest materials – and they find order in the sealing jumble quickly and easily.

More news on the subject Material Expertise

First Hand News

Best of all, keep up with the latest developments

with the Freudenberg Sealing Technologies newsletter.