Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

19.12.2023 | News

Don’t Let Flavor Retention Cost You Money

Downtime due to transfer retention can be costly, see how Fluoroprene XP saved a manufacturer almost 50% less downtime.

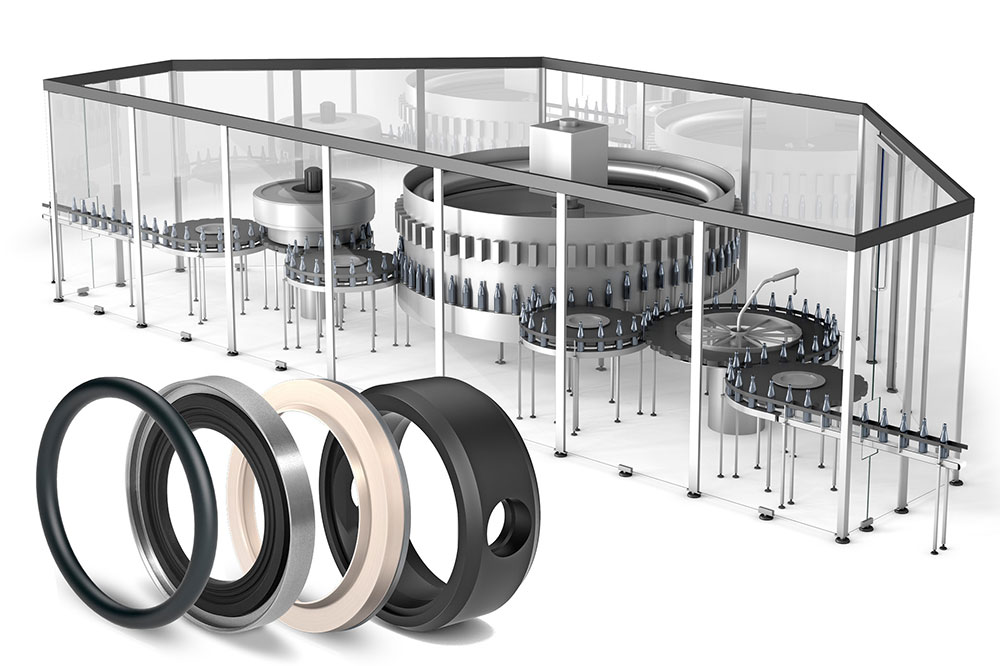

Often times people think that a seal is just a seal or that the materials don't matter, but this is far from the truth. No two sealing materials are exactly the same and have their own unique characteristics that make one material perfect for a specific application while another could completely fail. Materials are truly the foundation of every seal and can't be overlooked when you are considering what kind of seal to use. When you are working in the food and beverage industry and are exposed to challenging conditions and extremely strict purity standards the materials become even more significant. When you are working with a specialized application like a bottling line you want your seal manufacturer to be a true expert, this is where Freudenberg Sealing Technologies' long history of developing highly specialized materials sets us apart.

Flavor Retention Causes a Major Headache for Manufacture

A large beverage manufacturer in the United States regularly noticed they were having issues with flavor transfers affecting the quality of their products. At first, they tried to take more care with their changeovers between products by more deeply cleaning the lines and adjusting the cleaners they utilized. After taking these steps, they were disappointed to find the issue persisted and decided to increase the frequency they replaced the seals. Even with taking both of these steps they still were experiencing flavor transfers outside of their acceptable ranges set by quality control. Their facility is responsible for bottling a variety of products and experience almost 2,000 changeovers every year this created a lot of downtime and extra cost with labor, cleaning supplies, and seal replacement.

With the costs mounting and quality still not meeting their expectations, they reached out to one of our distributors who immediately contacted our team for assistance to solve this challenge.

How Specialized Materials Solved Flavor Retention

After reviewing the situation, our experts suggested switching the EPDM seals they were using and switching to the Freudenberg brand Fluoroprene XP. This material has proven to prevent significantly less flavor retention and transfer than an EPDM or FKM seal. Once the manufacturer changed to Fluoroprene XP they no longer had any issues with flavor transfers ensuring the quality of their products. Additionally, they have greatly improved their productivity as their changes take 50% less time all while saving a great amount in replacement seals, water, and cleaners compared to the EPDM seals they were previously using.

What is Fluoroprene XP

Fluoroprene XP is a premium allrounder material as it provides tremendous quality with the advantages of elastomers such as being a cost-effective solution. Its excellent performance in steam, hot water, and many alkaline solutions and acids makes it the preferred elastomer when used in CIP/SIP cleaning media and fatty as well as nonpolar media. FDA conformity, as well as branch-specific approvals like EG (Reg.) 1935/2004, NSF 51, and USP Chapters 87 and 88 (Class VI), stand for suitability for usage in the process industry. The material variant Fluoroprene XP 41 can be used for various seals: from O-rings, Clamp seals, and diaphragms to precision molded parts like pigs and butterfly valve seals.

Benefits at a Glance for Fluoroprene XP

-

No Flavor retention or transfer

-

Incredibly high media compatibility

-

Each compound meets a wide range of unique regulations

-

Performs from 5˚F to 392 ˚F ( -15˚C to 200˚C)

-

Reduces the number of changeovers required

-

Significant reduction in clean time, water, and cleaners needed during changeovers

-

For use in a wide range of types of seals

More news on the subject Material Expertise

First Hand News

Best of all, keep up with the latest developments

with the Freudenberg Sealing Technologies newsletter.