Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

01.04.2025

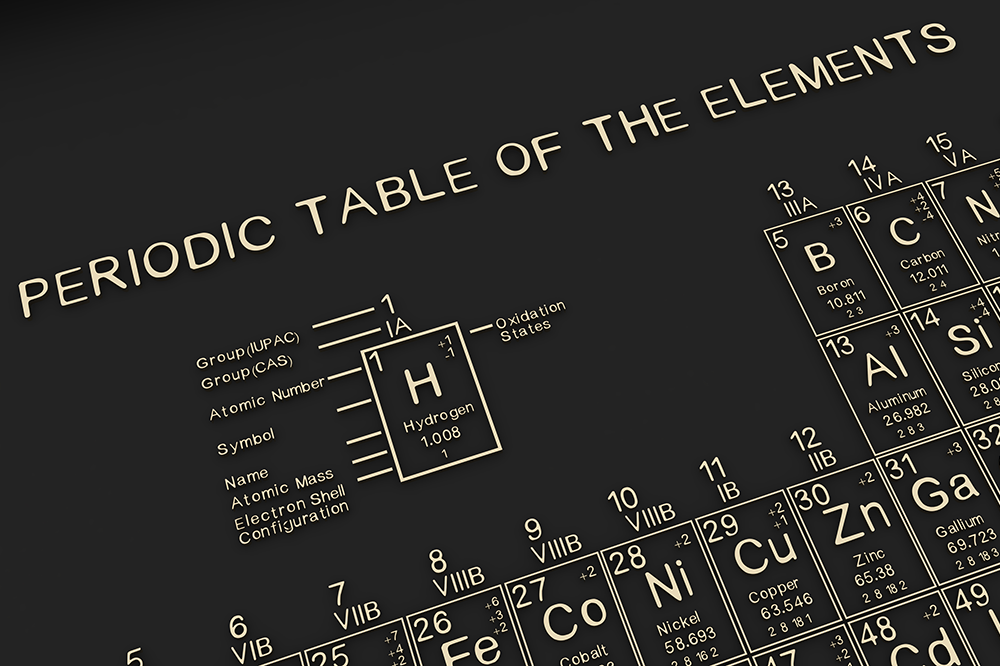

Freudenberg Sealing Technologies: Getting Hydrogen in Shape for the Future

Weinheim. High-performance seals play a central role in the hydrogen value chain – and Freudenberg Sealing Technologies can provide them. It is positioned as a technology partner for industrial companies, among other types of firms. Thanks to its vertically integrated production processes, the Weinheim-based material specialist can develop extraordinary sealing solutions and manufacture them in large volumes efficiently and sustainably. That is especially attractive to customers who want to be able to resize their production volume. Freudenberg Sealing Technologies is also active in standardization efforts to ensure process safety and reliability in the growing hydrogen economy. The company offers sealing processes for electrolysis, hydrogen compression, transport, and applications in fuel cells and hydrogen engines.

Seals for PEM and AEM – the core of the electrolyzer

Electrolysis is the main process for the production of hydrogen. Specific production processes require different sealing materials. For proton exchange membrane electrolysis, seals mainly have to withstand high pressures. In alkaline water electrolysis, a strong chemical and corrosive environment poses special challenges when it comes to selecting the right sealing material. Electrolysis using an anion exchange membrane could prove to be a cost-effective, efficient alternative to both of these processes – although the technology is currently not yet used in large facilities. Today Freudenberg Sealing Technologies is demonstrating its high level of materials expertise by providing seals that have been specially developed for these challenging environments.

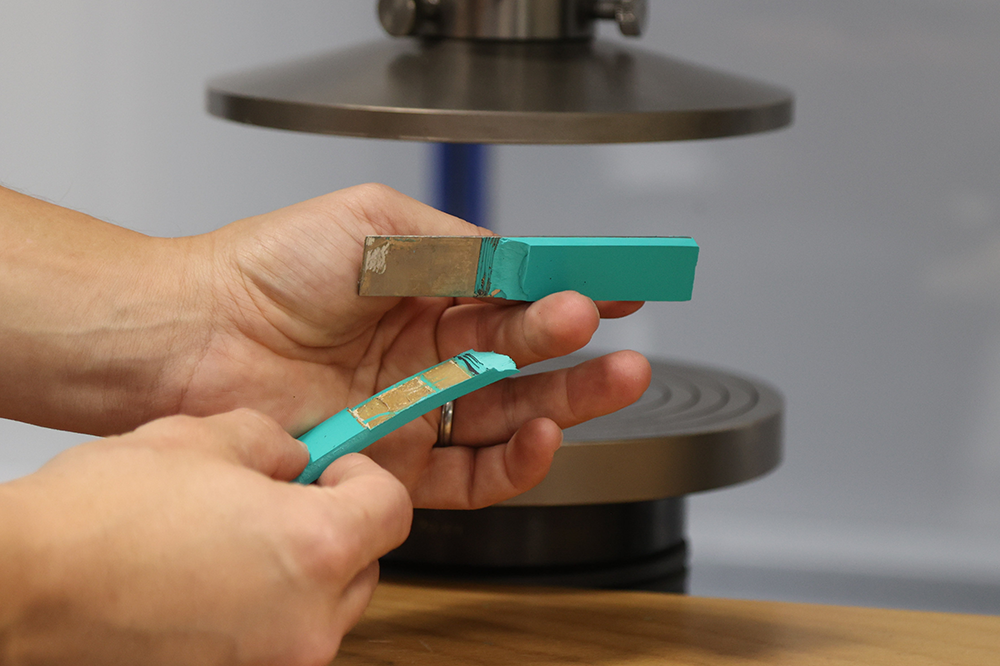

Compressor seals – the drivers for hydrogen compression

Hydrogen compression is a key element of the H2 value chain. Piston compressors are tremendously suited for the safe, efficient compression of hydrogen under high pressure. They have also proven themselves in recent decades. But even something good can be improved – the right combination of materials and design is crucial. Seals are needed that can be employed at high pressures and temperatures, as well as sliding speeds up to 5 meters per second. Freudenberg Sealing Technologies offers the latest compressor seals made of materials developed especially for hydrogen applications, giving the equipment a long operating life: They are wear-resistant, high-performance thermoplastics with special fiber reinforcements.

Hydrogen infrastructure – technically feasible and politically supported

The broad-based expansion of hydrogen infrastructure requires close interaction between industry and the political world. The technical challenges primarily relate to hydrogen's safe transport and storage. High-performance seals play a key role in this area, minimizing losses from diffusion while maximizing safety. Thanks to political subsidies and investments in innovative storage technologies, the hydrogen economy is becoming increasingly competitive. Freudenberg Sealing Technologies is showing which seal materials are suited to the construction of a dedicated hydrogen network, and which materials are available for safe sealing during pressurized and liquid storage. With the help of innovative materials, the entire value chain in the hydrogen economy is being optimized sustainably.

Seals in fuel cells – powertrain technology for heavy-duty transport

Hydrogen fuel cells have established themselves as one of the most important technologies for sustainable mobility. Especially in heavy-duty transport, including trucks and buses, they offer an environmentally friendly and efficient way to reduce CO2 emissions. Sealing solutions pose an important technical challenge to these systems since hydrogen molecules diffuse even through the tiniest pores. Specially developed sealing materials are therefore essential to prevent leaks and guarantee reliable operation over the long term. Specific sealing systems for fuel cells are expanding the performance range for the technology and maximizing the efficiency of hydrogen use.

Seals for hydrogen engines – ready for series production

In addition to fuel cell technologies, the hydrogen engine is becoming increasingly important. It is a promising alternative to conventional internal combustion engines and can help to reduce CO2 emissions. Freudenberg Sealing Technologies is highlighting specially developed seal materials that are market-ready for these technology sectors and that can already be integrated into the series production of hydrogen engines. Thanks to a combination of innovative materials and sustainable production processes, the company is superbly positioned to meet the demands of the hydrogen economy and advance the manufacture of environmentally friendly vehicles.

Technology partner – Freudenberg Sealing Technologie as a key player

Jürgen Emig, Director Product Pre-Development at Freudenberg Sealing Technologies, sums up the opportunities: “During discussions with our customers, we sense a positive mood, which unfortunately is seldom conveyed to the general public. Many companies – especially electrolyzer manufacturers – have promising projects underway, and a forward-looking growth market is emerging as hydrogen is used across sectors. We show how our customers can develop this market. With a combination of materials expertise and an openness to technology, we work closely with our partners and support them in many areas with solutions geared to the future, everything from design drafts to series production.”

Further Articles With These Taggings

First Hand News

Best of all, keep up with the latest developments

with the Freudenberg Sealing Technologies newsletter.