Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

On the Trail of Industrie 4.0

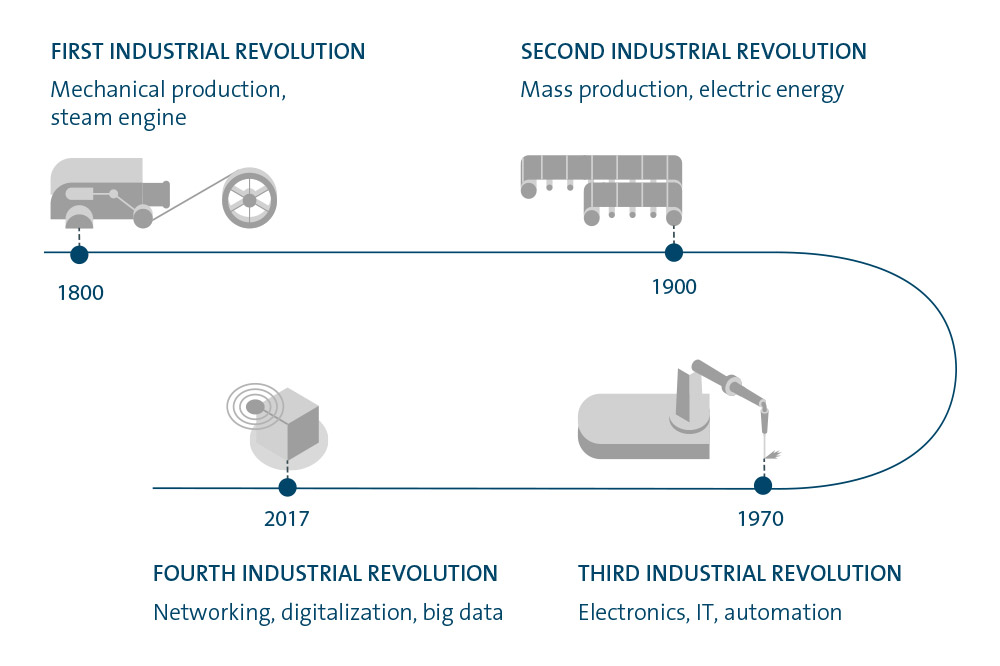

A lot has happened since the term Industrie 4.0 was first coined in 2011. Some visions were realized rather quickly. At the same time, however, there are still companies that are skeptical about the term, or experts who are calling for an even faster route to Industrie 4.0. But what is actually behind this term?

A lot has happened since the term Industrie 4.0 was first coined in 2011. Some visions were realized rather quickly. At the same time, however, there are still companies that are skeptical about the term, or experts who are calling for an even faster route to Industrie 4.0. But what is actually behind this term?

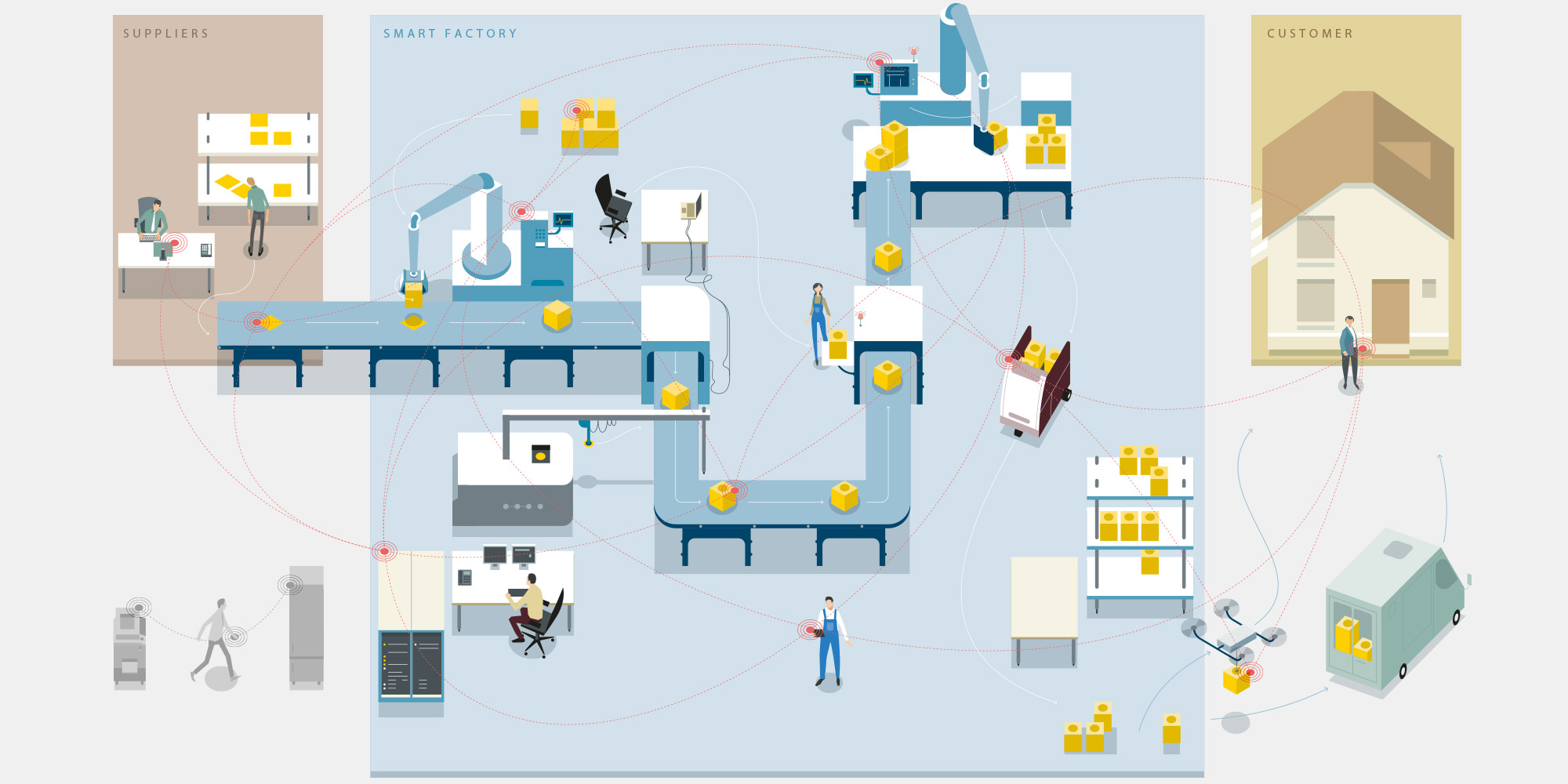

Industrie 4.0 is comprised of many different facets. This makes it somewhat diffuse. The factory is undoubtedly at the center of the next industrial revolution. However, unlike many past innovations, it is not so much the technology itself that triggers the decisive thrust, but rather the possibility of completely reorganizing processes. In the future, individual work steps will be even better coordinated thanks to comprehensive networking. Sensors in machines and products will ensure the necessary interaction and automated processes. And factory employees will be able to draw the right conclusions from data exchange in real time. All of this means that products can be manufactured and marketed more efficiently.

Even the customer will play an active role in production in the future. Whereas he can keep an eye on the current status of his deliveries already today, he will be able to trigger orders from home by directly controlling machines in the factory in the future. Industrie 4.0 will thus break down existing boundaries. The customer will be able to trigger production processes and help determine them. Lot size 1, i.e. the manufacture of individualized products, is no longer a utopia.

Flexibility and dynamics increase

Industrie 4.0 therefore introduces new dynamics to the factory. Networked vehicles are already core components in logistics today. Autonomous vehicles will also support the production process in the future. Robots will no longer be restricted to one location but can be deployed flexibly within the factory at different locations.

Networked and ever more flexible production will increase this speed. In addition, sensors in products and machines will avoid costly downtime due to unforeseen maintenance. They will signal the need for replacement even before the wear limit is reached or malfunctions occur. The production process will not come to a standstill; everything will be able to continue smoothly.

The most important components of Industrie 4.0 are illustrated at a glance in our infographic.

Where is digitization heading, what is it doing with us and what is behind this phenomenon? In our latest round of topics entitled “Digitalization,” we deal with these questions in depth and condense the topic in the next issue of our customer magazine ESSENTIAL, which will be published in May. Please also read our interviews with our COO Dieter Schäfer and our CFO Ludger Neuwinger-Heimes.

More Stories About Digitalization

Join Us!

Experience Freudenberg Sealing Technologies, its products and service offerings in text and videos, network with colleagues and stakeholders, and make valuable business contacts.

Connect on LinkedIn! open_in_new