Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

Enormous and Advanced

At least since Tesla conquered the roads with its electric vehicles, everyone has known that electric mobility can be elegant and fast. But there is also a massive amount of power in this promising variety of powertrain, as an example from Switzerland shows.

If you’ve ever stood next to a heavy-duty dump truck, you know the respect that the huge construction vehicle can produce in you. In mining, it is the vehicle of choice to carry off tons of material. The operator of a cement plant in western Switzerland relies on 45-ton giants in his quarry. They are capable of being loaded with 65 tons of material. The vehicles are powered by conventional diesel engines. But in recent months, the owner had one of his heavy-duty vehicles undergo an elaborate conversion. Starting in the spring of 2018, the truck will do its work with a purely electric powertrain. The first test drives proved to be successful.

Energy Recuperation an Advantage

The powertrain of the world’s largest electric vehicle consists of no less than 1,440 nickel-manganese-cobalt cells, packed into two batteries. They weigh a full 4.5 tons. The storage capacity totals 700 kWh, or nine times what Tesla’s Model S has. The real highlight of the conversion is related to vehicle’s constant uphill and downhill driving. When the heavyweight vehicle drives downhill to the plant from a quarry at a higher elevation with a full load, the battery is charged by the braking energy. The calculations envision that a little less energy will be consumed during the uphill trip with an empty truck than is recuperated going downhill. The excess energy can even be fed into the local grid. As a result, the so-called eDumper would never have to be charged. Over the next ten years, it expected to transport 300,000 tons, while saving 500,000 liters of diesel. Impressive figures, especially in times when the goal is to reduce CO2 emissions. In the meantime, the operator is planning to convert another dump truck to the technology.

Heavy-duty Haulers with a Diesel-Electric Locomotive Approach

The use of electric motors in huge construction vehicles is nonetheless not new. A Belarus manufacturer of heavy-duty dump trucks has turned to hybrid technology, among other systems, since 2014. When it comes to performance capacity, the Eastern Europeans' showpiece is clearly ahead of its Swiss counterpart. It is capable of handling up to 500 tons of material, and is powered by four electric motors generating – believe it or not – 6,500 horsepower. In theory, the massive vehicle functions like a diesel-electric locomotive, since two diesel motors each drive an alternating current generator, which ultimately feeds the four electric motors.

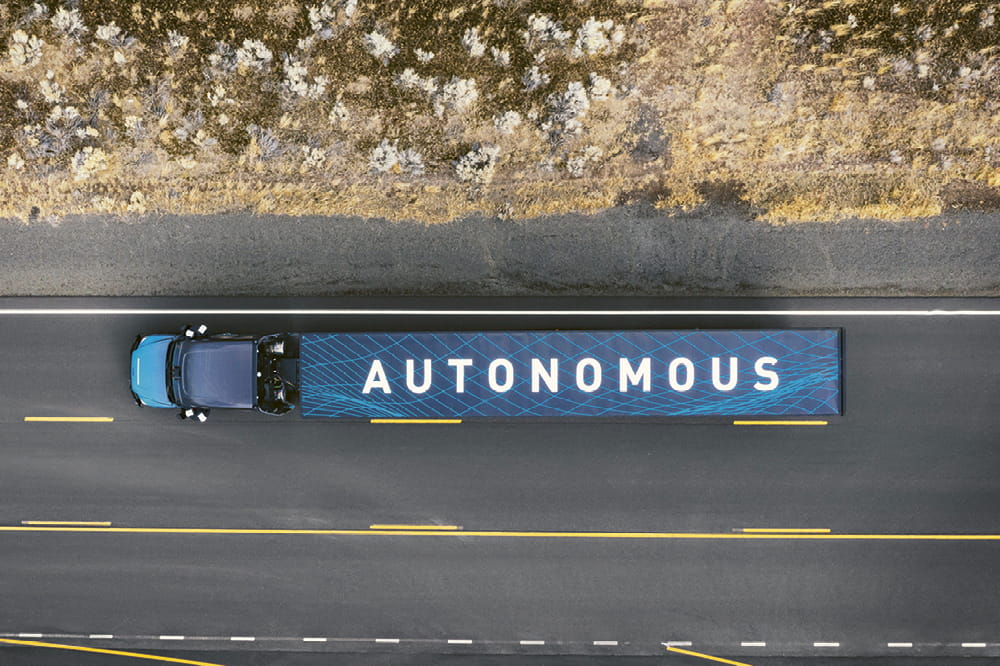

Autonomous Driving Long in Operation

Heavy-duty construction vehicles are not just proving themselves in alternative powertrain technologies. In Australia, certain dump trucks have been running quite progressively since 2015. Since then, a fleet of 69 vehicles has operated completely autonomously in two iron ore mines. To do this, the facilities in question were precisely mapped and measured so that the dump trucks could navigate without difficulty. A deployment center 1,200 km away monitors the sites to ensure proper driving operations. The mine operator is looking forward to more efficient and safer operations in the very remote mines of Western Australia with autonomous heavy-duty trucks.

Dump Trucks Totally without Cabs

In late 2016, a Japanese manufacturer presented a self-driving dump truck that totally dispenses with the driver’s cab. It is capable of driving in two directions and, in the end, doesn’t make a distinction between forward and backward. It looks like a huge trough on four wheels, which have a diameter of four meters. In light of these dimensions, it is an advantage that the new product can do without extensive maneuvering and instead change directions in one lane. The heavy-duty industry is showing that autonomous driving and alternative powertrain technologies are relevant to it as well. All the more because the emissions savings potential is substantial.

More Stories About E-Mobility