Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

05.10.2021 | Story

No More Sparks in E-Motors

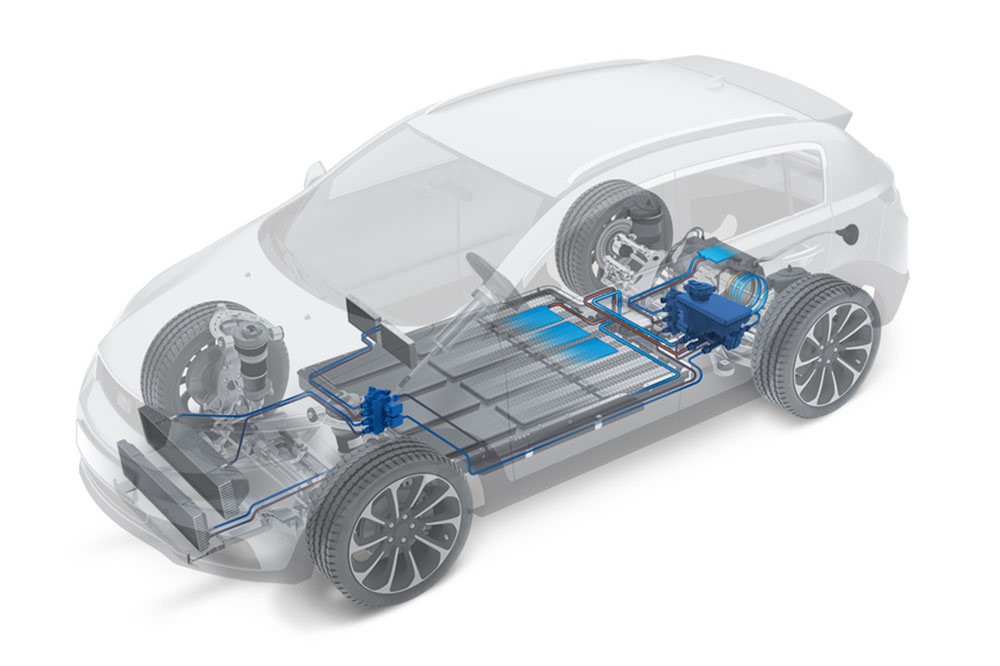

All the signs are pointing to electric mobility. That was the takeaway from the EU Commission’s announcement that no new internal combustion engines would be registered as of 2030. Many vehicle manufacturers have now announced they are concentrating on electric car production. Yet electric powertrains still have some technical weaknesses, including a propensity for bearing damage due to electric erosion. Freudenberg Sealing Technologies has addressed the problem – and solved it with a product known as eCON.

Imagine you have driven an electric car for years and suddenly the first problems appear while you are on a trip. The vehicle is vibrating noticeably and generating loud noises. “The source of the phenomenon is in the electric motor,” said Stefan Morgenstern, Advanced Developer at Freudenberg Sealing Technologies. “If the driver is aware of the vibrations and noise, then the bearings in the motor are already damaged. This is the result of electric erosion.” But how does this happen? Voltage builds up during driving and then discharges in the bearings, creating minuscule sparks that roll over the balls in the bearings and onto the rolling surfaces. The bearing surfaces are progressively damaged. “The surfaces are no longer smooth at that point. They are furrowed, which creates vibrations that can be felt and heard,” said Prof. Dr.-Ing. Eberhard Bock, Vice President, Technology & Innovation at Freudenberg Sealing Technologies. The consequences can be serious. “A damaged bearing of this kind has to be replaced. In the worst case, the motor breaks down if this is not handled promptly,” said Bock, who is also a university professor.

One Clear Solution with a Range of Benefits

Freudenberg Sealing Technologies learned of the problem of electric erosion early on. The company has long had close, trusting relationships with makers of electric vehicles. “In 2015, a French company informed us of the first damage to bearings that had occurred over a period of time. Since the manufacturer had confidence in our seals, we were asked whether we could tackle the problem,” Morgenstern said. The challenge was to drain off the built-up voltage to prevent sparking. Radial shaft seals offered a suitable starting point. After all, they create direct contact between the motor housing and the rotor shaft. “It would not have been enough to make changes in the seal’s elastomer,” Bock said. “So we turned to an electrically conductive nonwoven applied to the actual seal. It reliably directs the electric current past the bearings.” The solution, named eCON, proved to be the key to success. “eCON went into regular production back in 2015, and even today we haven’t heard of any field returns,” Morgenstern said. That’s one indication that the solution has proven itself in operation and has prevented bearing damage.

We see great potential for wide-ranging use in the many industries that rely on electric motors

Prof. Dr.-Ing. Eberhard Bock, Vice President, Technology & Innovation at Freudenberg Sealing Technologies

The system’s unbeatable advantage is that it is still the only integrated solution on the market. The nonwoven is simply glued onto the seal and takes up hardly any installation space. That’s an invaluable asset in a very compactly built motor. This is especially the case for companies who worked long and hard on the design of their electric powertrains and then ran into electric erosion at a late stage. With eCON, they don’t need a costly, time-consuming redesign – they can easily turn to the innovation and its benefits. Another asset: The use of nonwovens does not increase the assembly’s weight. Even other industries are taking notice, as electric erosion can be found in conveyor systems and many other applications. Morgenstern expects “the damage to increase in the general-industry segment with the growing use of frequency inverters.” eCON makes it possible to come to grips with bearing problems in this area. “We see great potential for wide-ranging use in the many industries that rely on electric motors,” Bock said.

Testing Method Expected to Become the Recognized Standard

To develop eCON and then demonstrate its performance, Freudenberg Sealing Technologies had to build a special test stand and find the proper measurement methods. It was pioneering work since the problem was new at the time. Morgenstern and a small team took up the issue and created a reliable measurement device. Other manufacturers with different solutions have come into the market, but each has a different approach to measurement. This leads to confusion among customers. There is no uniform standard. Bock spelled out Freudenberg’s goal: “We intend to develop our testing device into the generally accepted industrial standard.” Morgenstern added: “That means the more acceptance we have from customers, the more our test processes are considered the benchmark. This works because customers see that we understand and can describe everything from the problem to the methods of measurement, all the way to the product.”

In the meantime, eCONEVO has made it through the test phase successfully. The latest eCON development is the response to ever-higher-performing electric motors. It offers even greater electrical conductivity while preventing the emission of electromagnetic waves. “This is a crucial capability, especially for the U.S. market. This prevents the disruption of radio reception in the vehicle,” Morgenstern said. In the United States, radio stations broadcast on AM as well as FM frequencies. Electromagnetic radiation from the engine disrupts the listening experience on AM wavelengths. Sealing experts are already busy with the next project: wet-running eCON seals. Manufacturers are inquiring about versions cooled with lubricating oil. Since the nonwoven comes into contact with oil, a special system must be developed that does not neglect its main function: draining away electricity.

Impressive Presentation at the Vienna Motor Symposium

The renowned Vienna Motor Symposium during the spring of 2021 made it clear that Freudenberg Sealing Technologies is hitting the right note with eCON. Due to the corona pandemic, organizers of the venerable industry gathering extended invitations to a virtual event. In a fifteen-minute video, Morgenstern outlined the problem of electric erosion in electric powertrains and presented eCON as an impressive solution. “Just the fact that the organizers accepted us and our proposed topic was a very good sign,” Morgenstern said. “The feedback afterward confirmed our impressions. About one-third of all the participants viewed our video in the virtual space. Given the abundance of topics and videos, that was a very positive result. Our colleagues also reported a rise in customer inquiries about eCON.” This shows that the auto industry’s crème de la crème is increasingly turning to electric mobility, Bock said. “The Vienna Motor Symposium has been around for forty years and has fully established itself in the auto industry. This is where the very highest levels of the auto industry meet, and they used to have high-octane fuel in their blood. That has noticeably changed over the last few years. Electric mobility is breaking through.”

I thought it was important to give our young colleagues at Freudenberg the opportunity to direct projects and develop products.

Prof. Dr.-Ing. Eberhard Bock, Vice President, Technology & Innovation at Freudenberg Sealing Technologies

Bock is proud that an up-and-coming talent like Morgenstern was able to present eCON at the symposium. “There were definitely voices saying that we couldn’t do that at an important gathering,” he said. But he saw things differently. “I thought that anyone who had done such good work, as Stefan Morgenstern did, ought to be allowed to present eCON in all its impressive facets. In the process, he gained valuable experience, which helped him to grow.” The approach is an example of what Bock believes is the real issue: trusting the next generation of talent and promoting it to the best of the company’s abilities. The foundation is the acquisition of talent. Bock is a member of the scientific advisory panel of the Research Association for Powertrain Engineering (FVA). When it grants research contracts to institutes, its young experts lay the groundwork for companies in FVA and demonstrate their expertise. In this way, Freudenberg Sealing Technologies is always alert to talent and can attract people to the company.

Freedom to Demonstrate Their Abilities

“I thought it was important to give our young colleagues at Freudenberg the opportunity to direct projects and develop products,” Bock said. “After all, when they successfully handle assignments, their motivation not only increases – their visibility at senior management levels grows as well.“ That’s the way Morgenstern sees it as well. “Other junior staff have also been given the chance to take on responsibilities and gain experience at an early stage. We are given a great deal of freedom. This helps us and keeps us at the company. The Freudenberg company culture makes it very easy for us. It opens doors automatically as soon as you demonstrate your abilities.”

It is also important to Bock and Freudenberg that new and veteran employees work together. That allows different capabilities and approaches to flow into the work, stimulating the team and the search for solutions. “Learning from one another is standard practice,” Bock said. “Give and take in both directions is the rule,” Morgenstern added. That was shown in the above-mentioned testing process for eCON. Longtime employees contributed their process know-how, for example, while Morgenstern was able to exploit his strengths in the evaluation of the results. “Thanks to digitalization, we can now collect much more data than we could previously. My views were in demand in deriving the right conclusions from this massive volume of data.” This will continue to be the case. The development of high-performance eCON seals is continuing. The technology has piqued the interest of the auto industry, and Morgenstern wants to see the innovation contribute to electric mobility’s success. Best of all, without generating vibration or noise.

More news on the subject Automotive & Transportation

Join Us!

Experience Freudenberg Sealing Technologies, its products and service offerings in text and videos, network with colleagues and stakeholders, and make valuable business contacts.

Connect on LinkedIn! open_in_new