Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

On the Line

Building overhead lines for freeways and equipping trucks with pantographs – it sounds like science fiction. But if it works, the idea could contribute to a reduction in the rising CO2 emissions coming from freight transport on roads. It is now being tested on a heavily traveled autobahn in Germany.

A truck goes by every nine seconds, and the interval between two cars is less than a second. South of Frankfurt, the A 5 is one of the most heavily traveled stretches of autobahn in Germany. It goes through southern Hesse with four lanes in each direction. That makes it the ideal test lab for Gerd Riegelhuth, President of Hessen Mobil. A civil engineer, he is directing a project that is supposed to revolutionize freight transport on roads. If he proves successful, CO2 emissions from this form of transportation could fall dramatically. The need is urgent, since truck traffic is steadily increasing. Calculations by the German Federal Environment Agency found that, even if two-and-one-half times as much freight were transported by rail, truck transport in Germany would grow about 60 percent by 2050. The situation looks even more bleak worldwide. Without countermeasures, rising prosperity will lead to a doubling of CO2 emissions from road-based freight transport to 2.4 gigatons by 2050, according to the International Transport Form.

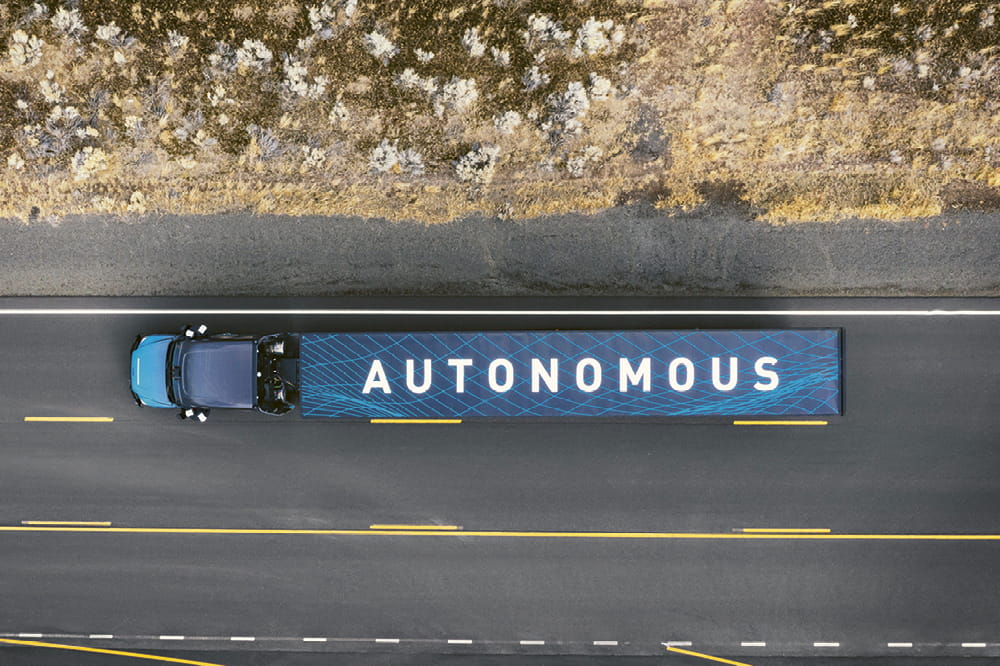

Long line: The test track on the A5 between Darmstadt and Frankfurt runs for several kilometers along the right-hand lane.

Toughest Field Test Yet

To prevent this scenario, the truck of the future must run on renewable energy, especially on solar and wind energy. This is not a trivial proposition. Experts estimate that a 40-ton truck would have to carry a 7 to 10-ton battery to even approach the range of today’s diesel truck. To deal with this issue, a consortium including Siemens, Scania and some other participants have been working on a truck that would use overhead wires. After thorough tests at a former military airport in Brandenburg, the German Federal Institute for Highways proclaimed the technology to be basically suitable for use. The first tests on public roads have been underway in Sweden and southern California since 2017, but on fairly short, less-traveled stretches. The technology still needs to pass the toughest field test. Under Riegelhuth’s direction, it starts in May 2019 on a 5-kilometer (3 mi) segment of the A 5.

Preparatory Measures

Electrification of the stretch of road has been completed since late 2018, after just a year and a half of construction. The right driving lane in both directions was equipped with an overhead line, supported by a total of 231 masts. The electric current will be fed to the system by two substations, one for each driving direction. They obtain their electric current from a medium-voltage network and convert it from 10,000 volts to 670 volts. The current also has to be rectified; while the grid operates with alternating current, direct current is required for the contact wires. The electric infrastructure basically corresponds to the systems familiar to users of trolley buses – from Switzerland, for example. The system lacks rails for electrical grounding; this is what mainly differentiates it from normal rail technology. Two contact wires are installed — a positive pole and a negative pole. They not only deliver the current – they also can be used to feed the energy produced on board (from braking, for example) back to the grid.

The four-lane A5 south of Frankfurt is the ideal test laboratory.

Gerd Riegelhuth, President „Hessen mobil“

Pantographs for Trucks

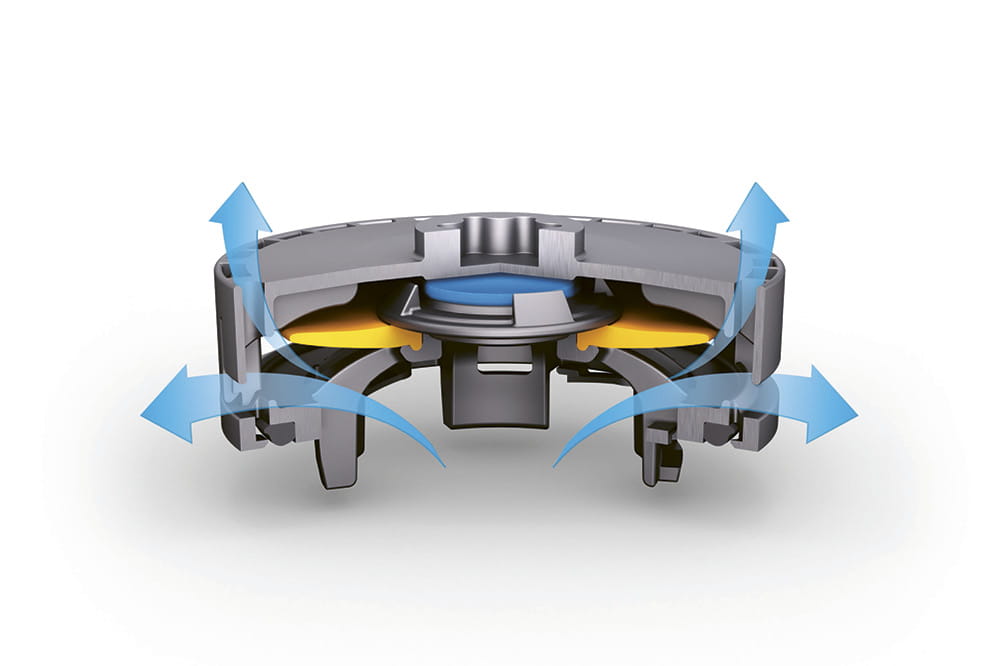

The truck itself is the greatest technical challenge. It needs a current receptor, called a pantograph, that takes up as little space as possible. It also has to extend out and withdraw safely at full speed. Otherwise, it wouldn’t be possible for a truck using overhead wires to overtake a slower vehicle or continue on its route if a lane were blocked. The researchers now seem to have found a solution after numerous tests. The pantograph lies on the roof of the cab and a two-part swivel arm guides it to the overhead line. The arm sits on an electric control center that is housed right behind the cab. This takes up a half meter (1.6 ft) of cargo space, but it was three times as large when engineers first began to experiment with its design. A dozen sensors, including a laser scanner, monitor the position of the pantograph, not just as the receptor is pressed against the overhead line, but during the entire trip.

Hybrid Solutions in Demand

The greatest advantage of trucks compared to freight trains is their flexibility – in theory, they can access any public street at any time. It is clear to advocates of pantograph-equipped, electrically-powered trucks that these vehicles must preserve this capability. Otherwise, they won’t get access to logistics companies. As a solution to the problem, all Scania trucks are designed as hybrid vehicles; they have an economical diesel engine that takes over whenever the vehicle travels on a non-electrified route. That is almost always the case after it exits a freeway. It also does not make sense to electrify every stretch of autobahn. A study by the German Federal Ministry of Transport found that 80 percent of the heavy-duty trucks registered in Germany could use the technology if just 30 percent – or about 4,000 kilometers (2485 mi) – were outfitted with overhead wires. So far, there are no comparable figures for global merchandise transport, but the transportation of goods is concentrated in major economic centers. The 94 large cities that have joined the C40 climate protection initiative represent one quarter of the world’s economic output.

Climate-Neutral Alternatives

Trucks can still operate in a climate-neutral mode when there are no overhead wires available – by not using fossil fuel in their diesel engines. Instead, they could burn a synthetic energy carrier produced with green electricity. Or the diesel engine could be replaced by a fuel cell that runs on hydrogen, provided that the gas is produced in a climate friendly way. Freudenberg Sealing Technologies is now arming itself with both technologies. For example, investigations at the company’s material labs are finding that the seals used in today’s fuel systems are also suited for substitute diesel fuels – if they are designed correctly. In parallel, Freudenberg Sealing Technologies is not just working on components of fuel cells – in the future, it also intends to provide the technology as a complete system for niche markets.

The results of the practical test on the A5 are available in 2022.

Test Phase until 2022

In 2022, it will become clear whether pantograph-equipped trucks will at least be a partial solution for climate-neutral freight transport. At that point, researchers will have the results of the field test on the A5, which started out with five vehicles. They have to prove themselves under real-life conditions at five mainly small- and medium-size companies. During the project, researchers from the Technical University Darmstadt are collecting the large amounts of data that would be needed if a fairly extensive infrastructure were ever to be built. For example, they are interested in knowing how much electricity the trucks will use and what the network loads will be. Riegelhuth is excited about learning the results, but he notes soberly: “There is no global formula for climate-neutral transportation.” Instead of lamenting that fact, he says: “We should always ask ourselves: What can we contribute?”

More Stories About E-Mobility