Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

26.11.2024 | Story

On the Way to a Hydrogen Infrastructure

The demand for green hydrogen is rising steadily. But how does it arrive where it is needed? Dr. Britta Mayerhöfer, Application Specialist, Hydrogen, Freudenberg Sealing Technologies, highlights the challenges and opportunities that a comprehensive hydrogen infrastructure poses.

Hydrogen is no longer considered merely an energy carrier of the future – and it hasn’t been for some time. It is seen as an important and established raw material in the chemical industry. Glassworks, steel mills and chemical plants – they all need hydrogen, whether for the production of ammonia and methanol or for the decarbonization of individual process steps. Green hydrogen is needed for the latter. “But it can often be produced more affordably, elsewhere,” said Dr. Britta Mayerhöfer, Application Specialist Hydrogen, Freudenberg Sealing Technologies. “This is why it is so important to create a good hydrogen infrastructure. The focus will first be on industry. This is where a large share of emissions can be avoided by using green hydrogen,” she said. Aviation and heavy-duty transport are next. “As soon as we have ample amounts of green hydrogen available, we can gradually use it for cars and even for heating.”

Planning certainty and support are needed to expand the supply of green hydrogen in the future.

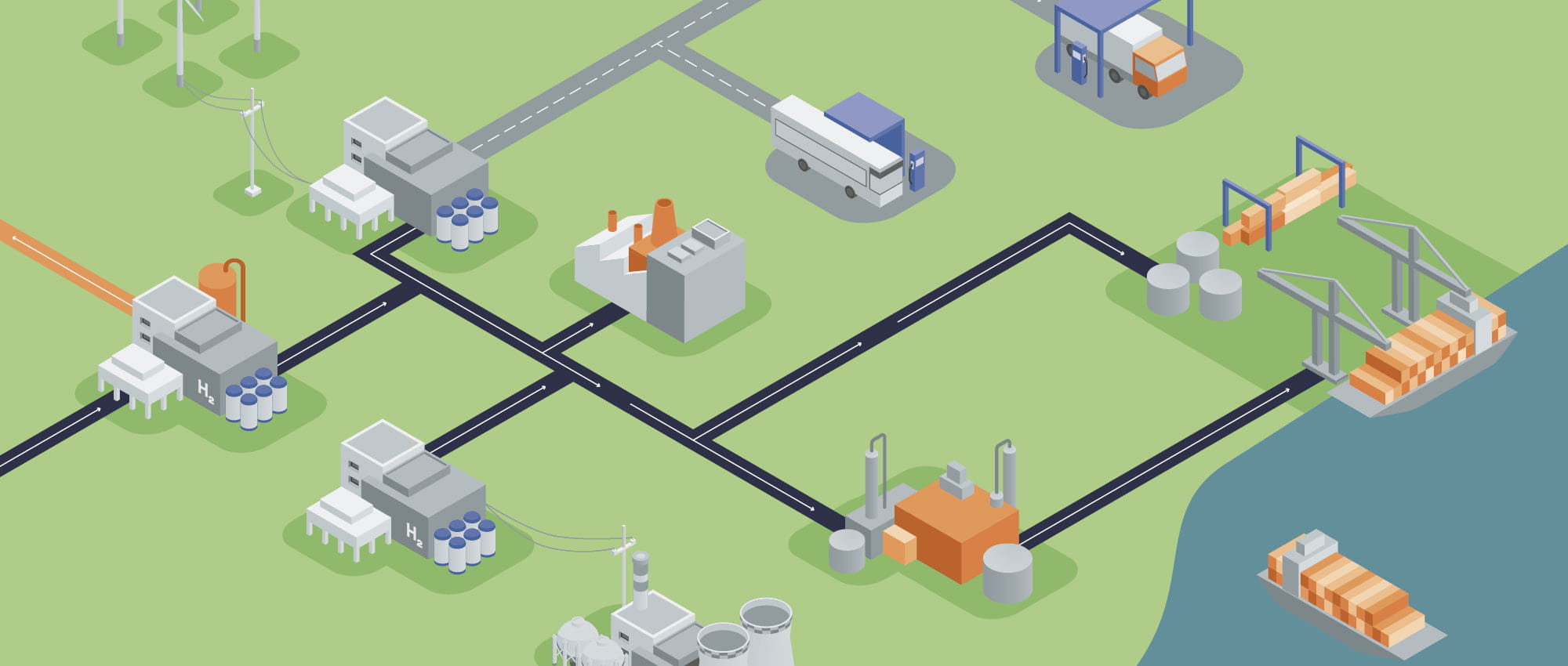

Imports via Shipping

The first task is to connect industrial sites to the ports. Especially in Europe, many countries will be dependent on the import of green hydrogen, long-term. It often comes from North Africa, South America and Australia – by ship. In gaseous form, hydrogen is too voluminous for this method of transport, which is why it is either liquefied or chemically transformed into ammonia, methanol or methane. The liquefaction of hydrogen is extremely energy-intensive. The gas 38 Hydrogen Transport Hydrogen Transport 39 has to be cooled to -253°C (-423.4°F) and maintained at that temperature. This approach is not commonly used for large volumes.

Before transport, nitrogen or carbon is added to the hydrogen to turn it into ammonia or methanol. Ammonia can be transported at a temperature of just -33°C (-27.4°F). Methanol does not need to be cooled at all. “The chemical industry needs both substances as precursor materials,” Mayerhöfer said. “If I can produce them with a green process, that is obviously an advantage.” The chemical industry has a great deal of experience with the transport of ammonia and methanol. But new challenges are proposed by the transport of the huge quantities that will be needed to cover Europe’s needs in the future. “For that, we would need sufficient intermediate storage or similar options. And not every port has suitable import terminals for loading and unloading ammonia or methanol,” Mayerhöfer admitted. These chemicals are a threat to bodies of water and subject to specific transport rules. If they escape, they are toxic to aquatic life.

Uniform European Infrastructure

Once the green hydrogen arrives on the mainland, it can be further transported by train, truck or pipeline. “As part of the Green Deal, people are striving for a uniform domestic market so that the hydrogen can be easily transported across national boundaries within the European Union,” Mayerhöfer said. But that’s easier said than done. “In Europe, a great deal of coordination is needed before a joint hydrogen network can be launched. That takes time,” she said. The situation is different in the United States, for example. “Here hydrogen hubs – that is, model regions – with a strong local focus are being set up. They cover almost every aspect of the value chain, from production to transport, all the way to the end-user.”

Dr. Britta Mayerhöfer

Dr. Britta Mayerhöfer is an Application Specialist on Hydrogen at Freudenberg Sealing Technologies. During her doctoral studies, she focused on electrolysis and electrochemistry and then worked on the development of proton exchange membrane electrolyzers and electrolysis components. At Freudenberg Sealing Technologies, she is responsible for business development in the hydrogen sector worldwide. “We are looking at the entire hydrogen value chain and are investigating applications for their potential and their relevance for different global regions.”

New Materials for Compressors

Hydrogen can be transported via pipeline wherever the networks of the future extend over the mainland. The advantage: neither liquefaction nor transformation is required. In some cases, even existing natural gas pipelines can be used, Mayerhöfer said. “As long as we are transporting natural gas as an admixture with 5-to-10% hydrogen content, the existing infrastructure can continue to be used for the most part.” But for pure hydrogen to go through the lines, a change in the equipment would be necessary. The seals along the pipelines would have to be checked for compatibility with the much more volatile hydrogen. Mayerhöfer sees compressors as the main problem. “The turbo compressors used in natural gas networks are not well-suited to create the required pressure for hydrogen. Yet compressors are critical to guarantee that hydrogen flows through the pipeline at the right pressure. “That’s why Freudenberg Sealing Technologies is focusing on the seals for piston compressors,” she said. “We are optimizing our materials precisely for the operating requirements of the compressors.”

Energy supply: LNG-Terminals könnten in Zukunft auch dafür genutzt werden, importierten Wasserstoff zwischenzulagern und weiterzuverteilen. © AdobeStock/Yellow Boat

A Lack of Certainty

So Freudenberg will be ready when the pipeline network is expanded. But the core hydrogen network is currently under construction and is not expected to be finished until 2032. And a crucial ingredient – the hydrogen – is still lacking. “That’s a basic problem. There is not yet enough green hydrogen for large investments in a comprehensive infrastructure to be worthwhile. On the other hand, it is hard to make a strong business case for hydrogen when the required infrastructure for transport and distribution is lacking,” she said. Unlike renewable energy, such as solar facilities, operating costs come into play, and not just investment costs. “Green hydrogen is still significantly more expensive than the gray variety, and companies have few incentives to invest in green hydrogen.”

Political leaders would have to create them. “Expanding the supply of green hydrogen will take planning certainty for both producers and consumers,” Mayerhöfer said. Since it is still under development, the regulatory regime is another reason for delays in the expansion of the hydrogen infrastructure. “At the moment, there are many ideas on the form of hydrogen and what route it will take from the production site to the end user. We are taking many directions in our research and development at once,” she said. But a clear framework is needed to ramp up hydrogen production and expand the infrastructure for it as quickly as possible. “Together with our customers, we have found solutions on a small scale for many of the challenges. As soon as we know where we are headed, we can start scaling them up.”

The Future Is Hydrogen

From H₂ Production to Usage: Comprehensive Insights on Production, Distribution, Storage, and Future Applications with Solutions. Explore full spectrum in our webspecial!

Hydrogen Webspecial open_in_newMore news on the subject Sustainability

Join Us!

Experience Freudenberg Sealing Technologies, its products and service offerings in text and videos, network with colleagues and stakeholders, and make valuable business contacts.

Connect on LinkedIn! open_in_new