Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

07.06.2022 | Story

“To Us, Handprints Are Important and Integral”

Sustainability is the key. More and more companies are understanding this. But what’s the most sensible way to achieve carbon neutrality? We talked with Dr. Bilguun Bayarmagnai, Head of Corporate Sustainability, about the resolute course the Freudenberg Group has charted.

Dr. Bayarmagnai, what do you personally associate with sustainability?

Dr. Bayarmagnai: Living responsibly. It is a matter of a conscious, well-thought-out approach to our resources. Especially as a father, it is important to me to be fair to the coming generations. That also means doing without.

What are you thinking about here?

Turning more to seasonal foods. Eating less meat. But also repairing instead of discarding. My children’s clothing is handed down from their cousins. We borrow books at the library. You don’t have to own everything. You don’t have to buy everything new. If something is manufactured, we should get the maximum use out of it.

As a chemist, how do you deal with sustainability?

I am fascinated by it. I associate it with innovation and efficiency. In my PhD thesis, I dealt with the development of sustainable methods to produce substrates resembling active agents. I worked with a hydrofluorocarbon gas. It is a waste product generated during the production of Teflon. It is difficult to discard. It is 14,000 times more harmful to the climate than CO2. So how do you deal with a byproduct of this kind in a constructive way? By binding the gas and transforming it, a waste product harmful to the climate is transformed into a valuable active substance.

Dr. Bilguun Bayarmagnai

Dr. Bilguun Bayarmagnai, who holds a PhD in chemistry, was born in Mongolia in 1988. When he was a young child, he accompanied his mother on her relocation to Germany for her studies and found a new home there.

He joined Freudenberg after earning his doctorate and completing a research assignment at CaRLa – Catalysis Research Laboratory – in Heidelberg. Since 2020, Bayarmagnai has been Head of Corporate Sustainability for the Freudenberg Group and, as a strategic guide, coordinates a project called “Sustainability Drives Climate Action” on behalf of all 11 Business Groups.

What role do science and engineering play in the effort to achieve resource efficiency and climate-related goals?

In my view, we are unable to achieve CO2 neutrality without technical innovations. Science must generate knowledge which experts in the corporate sector can turn into innovative products. The interplay of science and engineering is crucial to meeting the challenges of the future.

What challenges are you referring to?

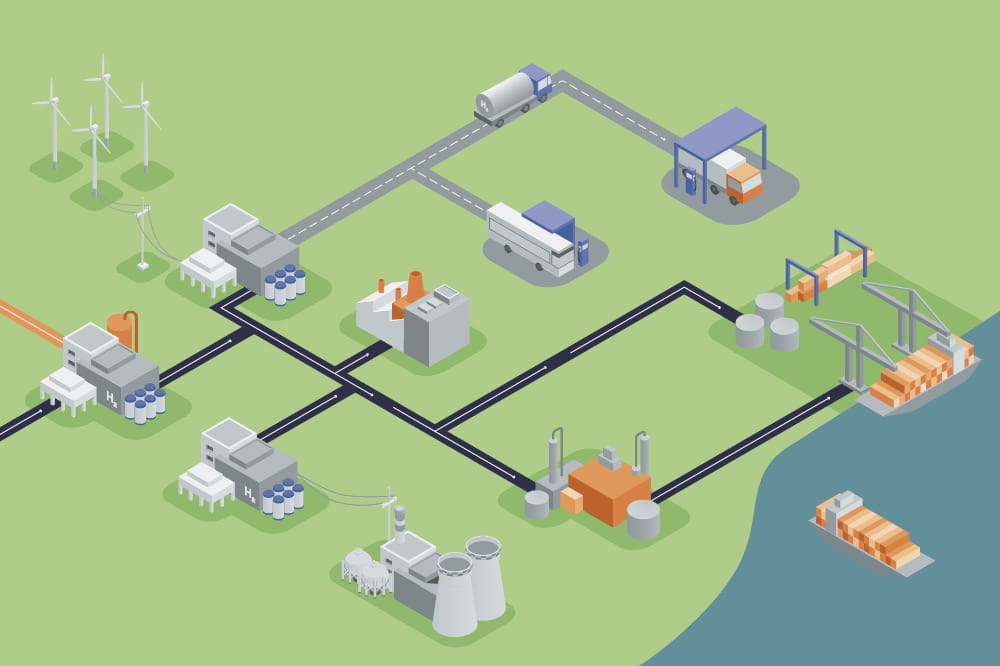

The reduction of CO2 and methane emissions in farming. The even more efficient generation of electricity from solar, wind and water power. Green hydrogen and electromobility as well. In the transportation sector, cars account for 47 percent of CO2 emissions, trucks for 30 percent. Electric vehicles will have a positive impact even when they use fuel cells, assuming that the electricity and hydrogen are generated with renewable energy. The technologies are ready. We must resolutely adopt them. We cannot wait until better ones are available. Considering the well-documented evidence of climate change, that would be a risk for our planet.

Resource efficiency: When Freudenberg talks about sustainability, the focus is on resource efficiency in energy and materials.

Sustainability found its way into the economy a long time ago. Wasn’t it always a driver for companies or do you see a new aspect today?

I assume that most companies act responsibly. But I actually have the impression that sustainability has become even more important in recent years. The planet is heating up. Climate change is becoming more urgent. The public has a greater expectation of climate-friendly behavior. People are confronting companies directly.

Why is sustainability so important to Freudenberg?

Because it has always been important. Even if the term is new, sustainability is an integral component of our activities. Our guiding principles and values emphasize the importance of assuming responsibility for society.

What does Freudenberg specifically mean by sustainability?

Resource efficiency in energy and materials. Our idea of sustainability is strongly influenced by the UN’s Brundlandt Report from 1987. It is a matter of being fair to future generations in our handling of resources. On this basis, we forged a common understanding of sustainability among all our business groups in 2015. There are two main dimensions in our strategy: First of all, minimizing our use of resources, our footprint. Secondly, using our products to maximize our customers’ resource efficiency, that is, optimizing the handprint.

The technologies are ready. We must resolutely adopt them. We cannot wait until better ones are available.

What does the Freudenberg group’s road to CO2 neutrality look like?

By 2025, we want to reduce our CO2 emissions by 25 percent based on revenue. In 2045, we want the entire Freudenberg Group to be carbon neutral. To achieve this, we have looked at and analyzed various levers over the last two years and set our course. Our program, “Sustainability Drives Climate Action,” consists of four steps: reduction, electrification, green electricity, and climate offsets.

What exactly does this mean?

We first reduce our energy consumption and our CO2 emissions by boosting our efficiency. We also want to electrify our technologies, minimizing our dependence on fossil-based energy, whenever possible, using green electricity that we either produce ourselves or purchase. We turn to offsets to cover everything that we still lack to achieve carbon neutrality. At present, we are focusing on the first three steps, since they are in our own hands.

Green electricity: Electrification of its technologies is a key lever for Freudenberg to reduce CO2 emissions. Preferably with green electricity, of course.

How has Freudenberg managed to become more energy-efficient?

With “Bee,” our “Be Energy Efficient” project. As part of “Bee,” teams analyze our facilities holistically. In the process, they continually ask themselves: What is the maximum level of energy efficiency that the site can achieve? The analysis results in a “to do” list of measures to take so we can reach this level. For example, we achieve very rapid results with heat recapture and the management of machine shutoffs. The same is true when we use our many air compressors more efficiently or acquire more efficient equipment that better fits our current requirements. With “Bee,” our facilities are scrutinizing their use of machines and energy consumption. We see potential savings averaging 25 percent in this area.

How is the electrification going?

We are checking to see which technologies use fossil fuels in our manufacturing operations and examining whether there are electric alternatives for them. Here electrification only makes sense if green electricity is available. It’s very difficult to electrify processes involving flames in production facilities. So we have to find alternatives.

What would those be?

Sticking with the technology, but using the most efficient equipment. Or optimizing processes. Consider the thermal afterburner as an example. At the end of a process, it incinerates chemical solvents and their gases. If we develop the process to the point where we don’t use solvents, we won’t need an afterburner.

There is still green electricity.

We have a team that is keeping an eye on its availability in individual markets and makes proposals on what we should do. One tried-and-tested approach involves bilateral long-term contracts with green electricity providers. By guaranteeing the volumes we are willing to buy, they can invest in their expansion.

Are all Freudenberg’s business groups on the same path to carbon neutrality?

The four-point plan applies to everybody. All are obligated to minimize the use of fossil fuels in manufacturing and to use green energy. But the forms and volumes of energy that are used vary considerably from group to group, since they depend on different production processes. So we leave it to them to choose a path and set the pace.

Green electricity is not available to the same degree everywhere. There isn’t even a price for CO2 everywhere. We consider this in our strategy. We have to reshape the situation.

Politicians are not setting the same standards and incentives for climate measures everywhere. How is Freudenberg taking countermeasures in light of its more than 200 production sites worldwide?

Green electricity is not available to the same degree everywhere. There isn’t even a price for CO2 everywhere. We consider this in our strategy. We have a way to reshape the situation. How? Wherever there is no CO2 price, we internally calculate 25 euros per ton of CO2 output. This allows the energy savings to more quickly amortize the investment. Sustainable investments thus pay off for our facilities in situations where no price has been set for CO2.

Goals are one thing. Showing that they have been attained is another matter. How is Freudenberg proceeding in this area?

It is important to measure our progress verifiably and make it transparent. This is important for our credibility and helps us with our internal controls. It is the only way to see whether we are moving at the right pace and are keeping an eye on our goal. Our facilities will become more efficient with these measures, and we want to show this. This year we started using a new tool for sustainability reporting to allow external auditors to check and confirm our key figures.

What do customers expect from Freudenberg’s business groups when it comes to sustainability?

Customer requirements have risen quantitatively and qualitatively in the last few years. This is reflected by the bidding processes. You are only considered if you have met certain sustainability criteria. For this reason alone, it is important to have a special strategy and reporting tool with verifiable data. We sometimes have very specific requirements. They range from the purchase of renewable energy and the proportion of recycled materials to the reduction of scrap. The amount of CO2 that our products release “baggage” over their entire lifespan is also of interest. In the end, the standards vary from customer to customer and from market to market. You find the most specifications and inquiries where customers have the highest expectations.

How does Freudenberg affect its customers’ handprints?

First of all, handprints are an important and integral component of product development. For each product, we ask ourselves how we can maximize its handprint. We make sure that we look at sustainability comprehensively and especially from the standpoint of the customer. This can be seen in the sealing and compressor solutions that one of our groups develops. They make it possible to significantly reduce methane emissions. The savings potential is the equivalent of several million tons of CO2. Another Freudenberg group recycles several billion PET bottles per year, keeping about 150 kilotons of CO2 out of the atmosphere. Freudenberg Sealing Technologies is setting a very good example by focusing on the reduction of friction, CO2, size and weight. Our customers appreciate this.

More news on the subject Sustainability

Join Us!

Experience Freudenberg Sealing Technologies, its products and service offerings in text and videos, network with colleagues and stakeholders, and make valuable business contacts.

Connect on LinkedIn! open_in_new