Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

18.10.2022 | Story

Transporting Electricity – The Environmentally-Friendly Way

In the future, massive quantities of electricity will have to be transported over long distances. But a gas 22,800 times as harmful to the climate as CO₂ is used as an insulator in the switching systems of local distributor and transformer stations. Now engineers are testing alternatives – using gases that put especially high demands on seals.

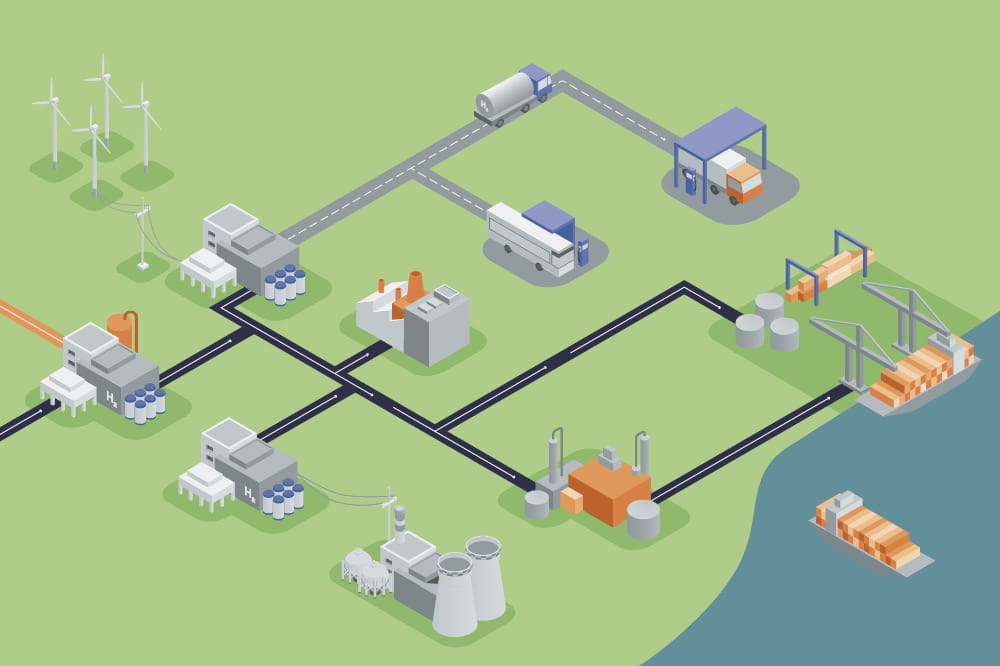

At first glance, the plan for a climate-neutral future seems simple. But electricity from wind turbines, solar facilities and hydropower cannot always be generated near consumers. So it is transported via high-performance grids and becomes an energy source for the transportation and heating sectors. To keep energy losses low, the electric current must flow through the grid at the highest possible voltage, which has to be transformed several times in the process. Electrical circuits in the switching system are switched on and off to control the grid.

Protective Gas Avoids Flashover

With the grid’s expansion, the number of these facilities is growing in urban areas that have little space available. To make the switching systems in the local distributor and transformer stations as compact as possible, the switches for high and medium voltages are encapsulated in a gas-tight arrangement. When a switch opens up and the metal contacts move apart, a special gas inside the switch ensures that the charge separation occurs quickly and that there is no flashover in the form of an arc. And if a flashover were to occur, the gas would extinguish the arc so the switch could function safely.

Sulfur hexafluoride (SF6) is one protective gas that meets these requirements well. It is fed into the switch at high pressure and features a very high dielectric strength when used as an insulation material – as a compressed gas, it can separate one electric charge from another reliably even under high voltage. It also extinguishes any potential electric arc immediately. An SF6 molecule consists of one sulfur atom and six fluorine atoms and is relatively large. Even that is an advantage since the molecule is not inclined to migrate through rubber – and therefore through the O-rings and special seals that, for example, seal the passage of the power lines through a switch housing. Freudenberg Sealing Technologies has developed seals that coexist with the protective gas in switches for many years. It is only when the gas pressure in the switch falls below a certain level that the SF6 has to be replenished during maintenance.

But this protective gas has a major disadvantage. It is more damaging to the climate than CO2 by a factor of 22,800. Experts call this capacity to damage the environment the global warming potential (GWP). Even if the gas takes a while to migrate through the sealing material, it will arrive in the atmosphere sooner or later. In 2014, in legislation to reduce fluorinated greenhouse gases, the EU began gradually limiting the available quantities of gases such as SF6, encouraging the search for alternatives. Meanwhile, a handful of potential materials have been identified that are all based on CO2 and, in some cases, are enriched with other ingredients. They are far more climate-friendly but have a major disadvantage: They migrate much more easily through sealing materials. “It is like a balloon,” said Dr. Robert Rotzoll, material developer at Freudenberg Sealing Technologies. “At first, it is filled to bursting, but over time the air or the helium escapes through the rubber surface.” Permeation is the process by which a gas penetrates or migrates through a solid body. And it is much greater for small CO2 molecules than it is for SF6.

It is like a balloon. At first, it is filled to bursting, but over time the air or the helium escapes through the rubber surface.

Dr. Robert Rotzoll, material developer at Freudenberg Sealing Technologies

Climate-Friendly Alternative Gases Pose New Challenges for Sealings

That defined the job for Freudenberg Sealing Technologies’ material developers. “The trick was to design a material did a balancing act among all the requirements,” Rotzoll said. In this case, it mainly involved the least possible permeation within a maximum temperature window range, from -50°C to more than 100°C. That was because the switching systems were supposed to be suited for cold regions such as Scandinavia and Siberia as well as warmer ones. In addition, the sealing material had to have a long lifespan and be resistant to aggressive media such as oxygen and ozone that act on the seal from its exterior.

After several years of development work, Rotzoll and his colleagues have now identified two materials that meet the higher standards for permeation, without having to accept declines in temperature resistance. One material was based on EPDM, and the second is synthetic rubber based on chlorobutyl (CIIR), which stands out for its low permeability to gases and liquids and is used in the tire industry and other sectors. “The development of the new O-rings for climate-friendly alternative gases is complete, and we have already installed seals based on chlorobutyl in prototype switches,” Rotzoll said. “Now it is a matter of jointly testing them with our customers.” If the tests succeed, it will be possible to transport electricity from renewable sources in an even more climate-friendly way.

O-Rings: Statically and dynamically sealing at the highest quality level. Find out more on our website.

Note: This article first appeared in Freudenberg Sealing Technologies’ ESSENTIAL Magazine in May 2018.

More news on the subject Sustainability

Join Us!

Experience Freudenberg Sealing Technologies, its products and service offerings in text and videos, network with colleagues and stakeholders, and make valuable business contacts.

Connect on LinkedIn! open_in_new