Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

Detecting Leaks in Just 120 Seconds

Leaks are a headache for any industrial company. They are costly, they can lead to subsequent damage to equipment, and, in the worst case, they put people in danger. In 2021, Freudenberg Sealing Technologies brought out a system that is just as flexible as it is simple. It reliably detects leaks and triggers an alert within just two minutes.

Production facilities in the process industry often have pumps, tanks, valves, pipes and lines in their systems. Leakage can result if components are installed incorrectly, weld seams are flawed, or seals have reached the end of their life cycle. Liquids such as water, oils and chemicals can then escape or spill over. Operators are only too happy to avoid these scenarios. Ultimately, the escape of fluids can prove costly and even pose a risk to employees and equipment.

Compact and smart: sensor technology and special nonwovens by Freudenberg ensure that leakages do not go undetected with the sensors of the Leakage Control System (LeaCo).

A Brilliant Idea Ahead of Its Time

So how wonderful would it be for the operator of an industrial installation to have a flexible, affordable monitoring system that detects and immediately reports leaks? Guido Brüggemann has given much thought to the idea. About twenty years ago, the managing director of the Freudenberg Sealing Technologies‘ Zürich Service Center took part in the development of this type of system. It was a “wired” version, and it did actually detect leaks as planned, but its application turned out to be largely impractical. “It was ultimately important from a customer’s standpoint for the system be as flexible and standardized as possible and operate without wires,” the Swiss manager recalled. “What I had in mind was something easy to install and suitable for the retrofitting of existing equipment," Brüggemann said. In 2005, he documented his idea for a wire-free monitoring system and had it patented. But there was a problem: The technology was not there yet, but time was on Brüggemann’s side. So were advances in technology: “In the last few years, the necessary technology was ready. It enabled us, for example, to control sensor operation as we wished and achieve the right radio intervals.”

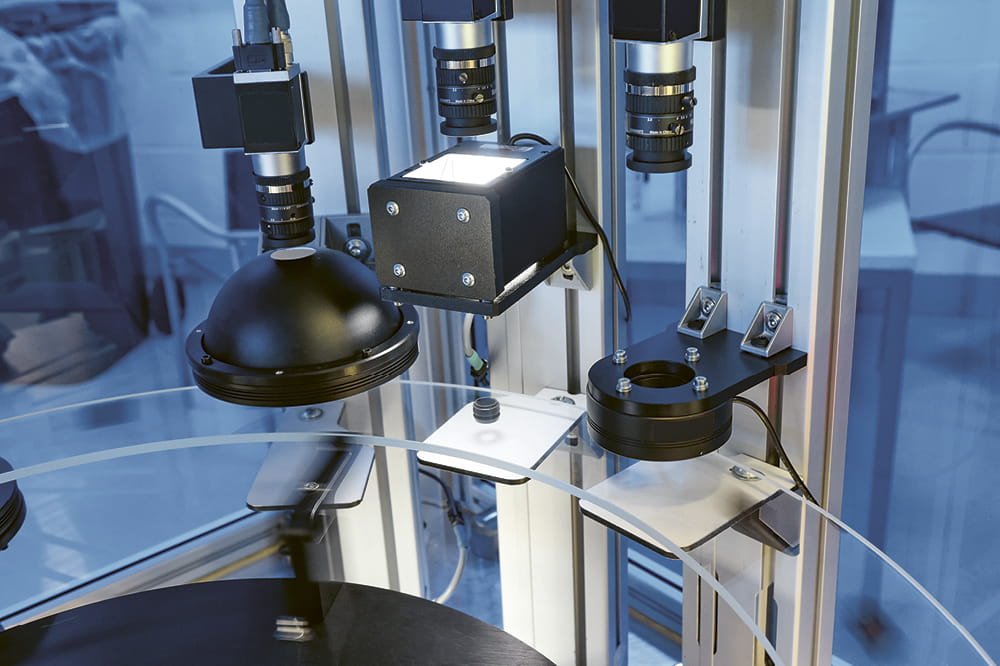

By 2021, the patent had finally become a wireless, market-ready product. The Leakage Control System (LeaCo) from Freudenberg Sealing Technologies consists of a display within the receiver module, along with one or multiple small sensors that detect leaks. When necessary, the radio signal between the sensors and the display can be boosted with one or several repeaters. The LeaCo case contains everything that the sensors, which are about 5 centimeters (2 inches) high and 4 centimeters (1.6 inches) wide, need to detect an area susceptible to leakage: a battery, a processor, a light source and a piece of a special Freudenberg nonwoven. The interplay of these elements ensures that checks are run every two minutes; they detect whether the nonwoven has absorbed a fluid. If so, the sensor sounds the alarm. LeaCo thus will detect the escape of liquid media in 120 seconds at most. The alert is communicated to the display module, which, if desired, sends a short message to the smartphone of the employee who is responsible for the equipment. The automated process allows him to respond to the leak even when he is off-site.

Self-sufficient System Relies on Radio Technology, Special Nonwovens

Both the sensor technology and the special nonwoven are Freudenberg developments. “The capillary action of a nonwoven worked in the material’s favor,” said Application Engineer und Co-developer Wulf Geiselhart. “If a liquid reaches the sensor, the nonwoven soaks it up like blotting paper and distributes it evenly.” The type of liquid doesn’t matter – it can be chemicals, water, oils or even the beverages that are produced and bottled in large processing facilities. The processor recognizes whether the nonwoven has absorbed any liquid via an optical unit that it controls. If the refractive behavior of the light changes, the processor then concludes that the nonwoven is no longer dry and there has been a leak. The operator is alerted and is immediately in a position to take steps to stop it.

It was important from a customer’s standpoint for the system be as flexible and standardized as possible and operate without wires.

LeaCo operates completely self-sufficiently. One key element is the transmission of reports via radio technology based on 868 megahertz. "That means the monitoring system is not based on WLAN or Bluetooth. It also does without a PC connection or platforms from other manufacturers,” Geiselhart said. The use of button batteries as an energy source underscores the system’s self-sufficient nature. The batteries are designed to have a life cycle of five years. When the output of a sensor battery is no longer sufficient, the operators of the equipment are notified.

A Fail-safe System

The operators decide where the sensors should be mounted on the equipment. With LeaCo, they get the maximum flexibility to deploy the monitoring system wherever leaks might occur – at tanks, lines, pumps, valves and pipes, for example. The sensor can be screwed on below the point of interest or attached with a magnetic or adhesive film. Up to 40 different locations can be equipped with sensors and connected to a single display module, which serves as the monitor. An alarm is triggered if a sensor ever loses contact with the display (the connection is checked automatically every 30 minutes). If the display module ever has too little energy due to a power failure, the responsible party receives a text message on his smartphone. In this way, LeaCo ensures that the failure of a sensor or the display will be discovered – and that leaks will not go unnoticed.

Freudenberg Sealing Technologies has also developed repeaters to facilitate the transmission of the radio signal to the display. They are especially recommended for labyrinthine or multistory buildings. “The signal from the sensors reaches up to 400 meters (437 yards) outdoors,” Geiselhart said. “Since we recommend LeaCo for use in enclosed spaces, building materials and a facility’s architecture may have a significant impact on the quality of the radio connection. The repeaters then ensure that the radio signal is forwarded reliably.” One repeater comes with the LeaCo starter kit, along with one display module and three sensors. The system can also be retrofitted with up to 40 sensors.

Ready to Use in Just a Few Minutes

This self-sufficient, flexible monitoring system was greeted with a positive response at its introduction in 2021. Test customers had already confirmed that the system has reliably detected and reported leaks during simulations. They also stressed its convenient handling. Even beginners can get LeaCo up and running in just a few minutes. Once it is clear where the sensors are to be attached, they can be installed and connected to the display with just a few manual steps. Furthermore, the sensors can be renamed in the display, which makes it easy to assign locations.

Liquids of all kinds: LeaCo sensors detect the leakage of any liquid. From water to oils and chemicals to beverages, such as those produced and bottled in breweries.

LeaCo is certainly not the first monitoring system on the market, Brüggemann noted. "In fact, there are many systems. But none of them offers as many unique selling points as LeaCo does. There currently aren't any that are as multifaceted, straightforward, affordable and flexible," he said. Its wireless monitoring offers limitless opportunities for its use. LeaCo gives the owners of existing installations a priceless opportunity: integrating the system is child's play, and no new construction is required. The sensor has deliberately been kept small and compact so it can even be mounted below rotating shafts and valves. One final advantage: LeaCo stands out for its price. The cost of a starter kit has been deliberately kept to a minimum. This simplifies the purchasing process at many companies, as there are usually no investment requests to submit.

More Applications Are Possible

Even though LeaCo was first conceived for use in industrial facilities, an expansion into other areas is a real possibility. For example, it could exploit its strengths in private households, perhaps sending out alerts when washbasins or bathtubs overflow. “We are already considering how LeaCo could be used as a carrier for temperature, noise or vibration sensors,” Brüggemann added. “That would help companies monitor the condition of gearboxes and bearings.” Freudenberg Sealing Technologies also wants to look at another option: how LeaCo could be integrated into existing monitoring systems. That would give customers attracted to the concept the best possible tool to identify leaks. LeaCo will ensure that they won't be missed any longer.

More Stories About Technology

Join Us!

Experience Freudenberg Sealing Technologies, its products and service offerings in text and videos, network with colleagues and stakeholders, and make valuable business contacts.

Connect on LinkedIn! open_in_new