Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

Success Is in the Details: Seals Blazing the Trail for Humanoid Robots

Humanoid robots are an important growth market, not least of all due to their many expected uses. These two-legged machines are not only likely to work in factories and warehouses but in mining and caregiving as well. Freudenberg Sealing Technologies is supplying a manufacturer of these sophisticated robots with sealing solutions made of high performance materials and with special designs.

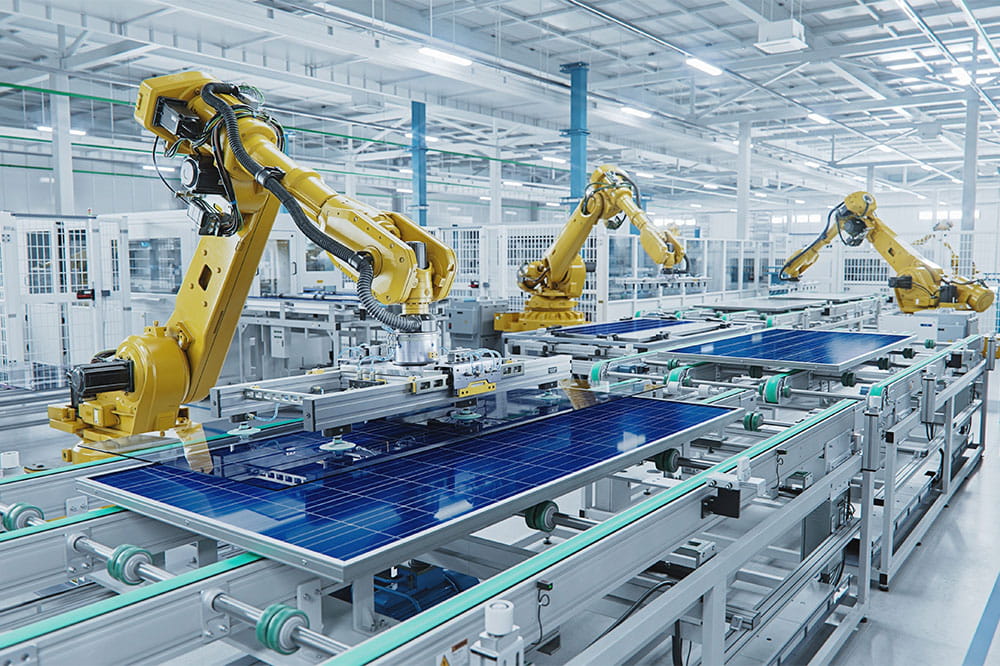

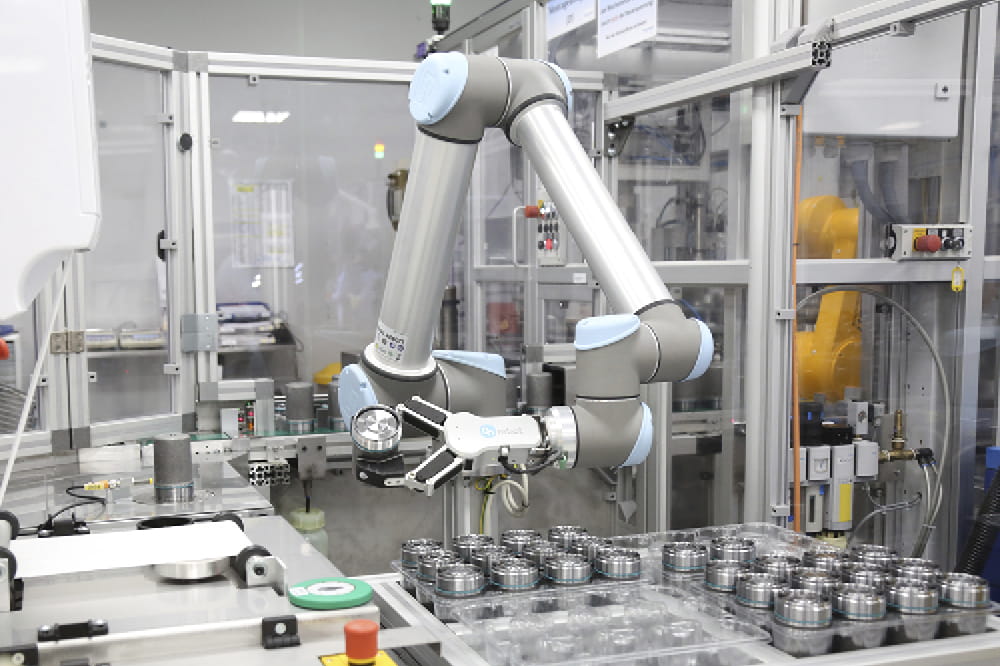

Today there is no way around the use of industrial robots in manufacturing. They work diligently, precisely and quickly. Some of them can even move enormous loads. In these ways, they are helping to accelerate and automate production processes. Or they are making a contribution to warehouse logistics. In the future, a new form of robot could begin making inroads in industry and even beyond it: humanoid robots.

Our expertise in the development of made-to-order solutions for classic industrial robots makes it easier for us to provide seals for humanoid robots that satisfy the machine’s requirements all the way to its finger joints.

Gregg Goings, Global Segment Manager at Freudenberg-NOK Sealing Technologies.

Practical Tests in a Promising Market

In 2024, BMW made a splash when it used some of these human-like robots in a factory in the United States. The two-legged figures, roughly 1.7 meters (5’7”) tall, were used in the body construction and in sheet metal processing. Amazon has also tested the use of humanoid helpers in its U.S, warehouses. The two examples show that different industries are already dealing with applications for humanoid robots and weighing their advantages for their particular business models.

In any case, the market for humanoids is likely to steadily expand. According to a study from Fortune Business Insights, the global market for this type of robot was about US $2.43 billion in 2023. Asia accounted for the largest share, it said. By 2032, the market is expected to grow to a whopping US $66 billion US. That would be more than the entire current market volume for robots, which today stands at about US $46 billion worldwide.

Proven Sealing Solutions from Industrial Robotics

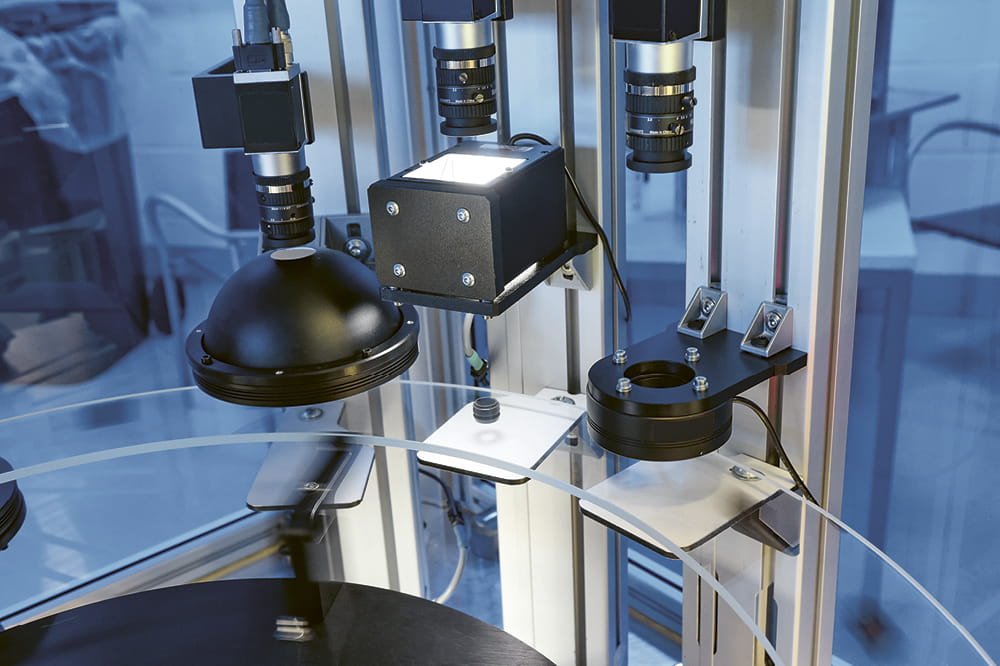

Freudenberg Sealing Technologies considers humanoid robots to be a young but not unfamiliar field. “Our expertise in the development of made-to-order solutions for classic industrial robots makes it easier for us to provide seals for humanoid robots that satisfy the machine’s requirements all the way to its finger joints,” said Gregg Goings, Global Segment Manager for New Business at Freudenberg–NOK Sealing Technologies. Seals play a key role, especially in the built-in actuators that initiate the robots’ movements. They must be extremely robust and long-lasting. Low-friction seal materials are also in demand. “Our IPSR seal has these attributes,” Goings said. “Due to its characteristics, including its wear-resistant material, it provides outstanding protection against harmful environmental influences such as dust or the penetration of water.” It also performs well in very small installation spaces and can compensate for both axial and tangential displacements. The IPSR seal is already being built into humanoids by a well-known international robot manufacturer.

Humanoid Robots

Well known: Freudenberg Sealing Technologies develops customized solutions for industrial robots and benefits from this knowledge when it comes to seals for humanoids.

They are human-like machines, the first of which are being used in factories, hospitals and in the service sector. They have a head, rump, two arms, and usually two legs. They are driven by electric, hydraulic or pneumatic actuators – the robot’s “muscles.” Sensors deliver information on the environment and positioning. Artificial intelligence and pre-programmed algorithms control their actions.

The PSS seal from Freudenberg Sealing Technologies is also an option for humanoid robots. “Thanks to its remarkable qualities, it has long proven itself in the motors and gearboxes of industrial robots,” Goings said. With its unique design, it seals reliably both externally and internally, preventing contamination. Due to its low friction, this long-lasting seal ensures that less of the robots’ performance is lost over time. PTFE wafer seals from Freudenberg Sealing Technologies also exhibit outstanding results for friction reduction. In addition, these disk seals made of high-performance PTFE plastic are water-repellent and in demand in various industries.

Materials for Battery and Heat Management

Miniaturized solutions are a wide-ranging trend in the industry. In the case of humanoid robots, it relates to the batteries that provide the machines with power and that are mostly installed in the robot’s thorax. But the batteries are not just expected to be more compact today – they should offer higher performance as well. But that tends to generate more heat, which is why the materials surrounding the batteries must be heat-resistant. Once again, thanks to its extensive material expertise, Freudenberg Sealing Technologies has the right solutions in its portfolio. The company has recently developed a thermoplastic – Quantix® ULTRA – that can withstand temperatures as high as 1200°C (2192°F). This material is suitable for use in close proximity to electric-vehicle batteries since it meets the flame-retardant requirements for these environments. In the case of electric powertrains, the material is an option for the encasement of important electrically conductive rails known as busbars. They are also in demand for humanoid robots, although on a smaller scale. Freudenberg could offer package solutions in the battery area to help with heat management in these sensitive robots.

“We have now visited several makers of humanoid robots and shared information with many of them at trade fairs,” said Hunter Cheng, Global Segment Manager, with a focus on robotics, at Freudenberg Sealing Technologies. “When we talk to them, we continue to see just how much these manufacturers are interested in our expertise in developing materials and designs.” Freudenberg Sealing Technologies has a wide-ranging portfolio of products and designs that are a good fit for any application. “When sealing products have to be tailor-made, we can do it,” Cheng said. “We’ve shown that often enough. Whether in the field of robotics or the manufacture of machinery and automobiles.” The success of Freudenberg Sealing Technologies is based on in-depth material research and development. In combination with its in-house test facilities, it is able to create solutions that are highly performing and innovative in equal measure.

When we talk to them, we continue to see just how much these manufacturers are interested in our expertise in developing materials and designs.

Hunter Cheng, Global Segment Manager, with a focus on robotics, at Freudenberg Sealing Technologies.

Robust and long-lasting: A manufacturer of humanoid robots relies on IPSR seals. Their characteristics provide reliable protection against harmful environmental influences such as dust and the penetration of water.

Equipping Humanoids for Use in a Demanding Environment

What makers of humanoid robots also have been looking for are seals that have a damping effect. They should reliably keep moisture out as well. “Both are the preconditions for the new class of robot to develop new areas of application,” Cheng said. “The humanoids are not expected to work solely in factories and warehouses but in caregiving and outdoors in harsh weather and working conditions too.” That means the seals in the highly sensitive joints, in particular, must be especially resistant to dirt and the penetration of moisture. In the future, it is conceivable that humanoid robots could be used in potentially hazardous environments such as mines. In that case, the seals themselves and the materials will have to be extraordinarily robust and durable.

When it comes to boosting the potential of humanoid robots, it will be important to teach them quickly. So far this still is a tedious process. Cheng is convinced that machine learning can be accelerated with the use of electromagnetic rubber compounds for muscular movement, neural signal and even brainwave transmission. These have been widely applied in Asia for life science applications. If they were applied to the hands of the humanoids, they then could relay haptic signals that the robot could process. The signals then culminate in the right movement. With its material expertise, Freudenberg Sealing Technologies could provide valuable support in not only remote control but also an alternative way of machine learning which could be more intuitive and efficient than traditional programming and video shadowing. Cheng is confident about the opportunities. “These are still ideas. But we have such an extensive knowledge of materials that we could certainly move in the direction of electromagnetic materials,” he said.

With its already existing solutions such as ISPR, PSS, busbars and PTFE wafer shields, Freudenberg Sealing Technologies is laying the foundation to expand humanoid robots’ range of applications while increasing their safety, longevity and range of functions.

Explore Our Advanced Robotics Solutions

Visit our robotics solutions page to learn about our innovative materials and technologies that support a wide range of robotic applications, including future advancements in humanoid robots.

Explore Robotics SolutionsMore Stories About Technology

Join Us!

Experience Freudenberg Sealing Technologies, its products and service offerings in text and videos, network with colleagues and stakeholders, and make valuable business contacts.

Connect on LinkedIn! open_in_new