Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

18.07.2017 | Press release

Following Shaft Runout

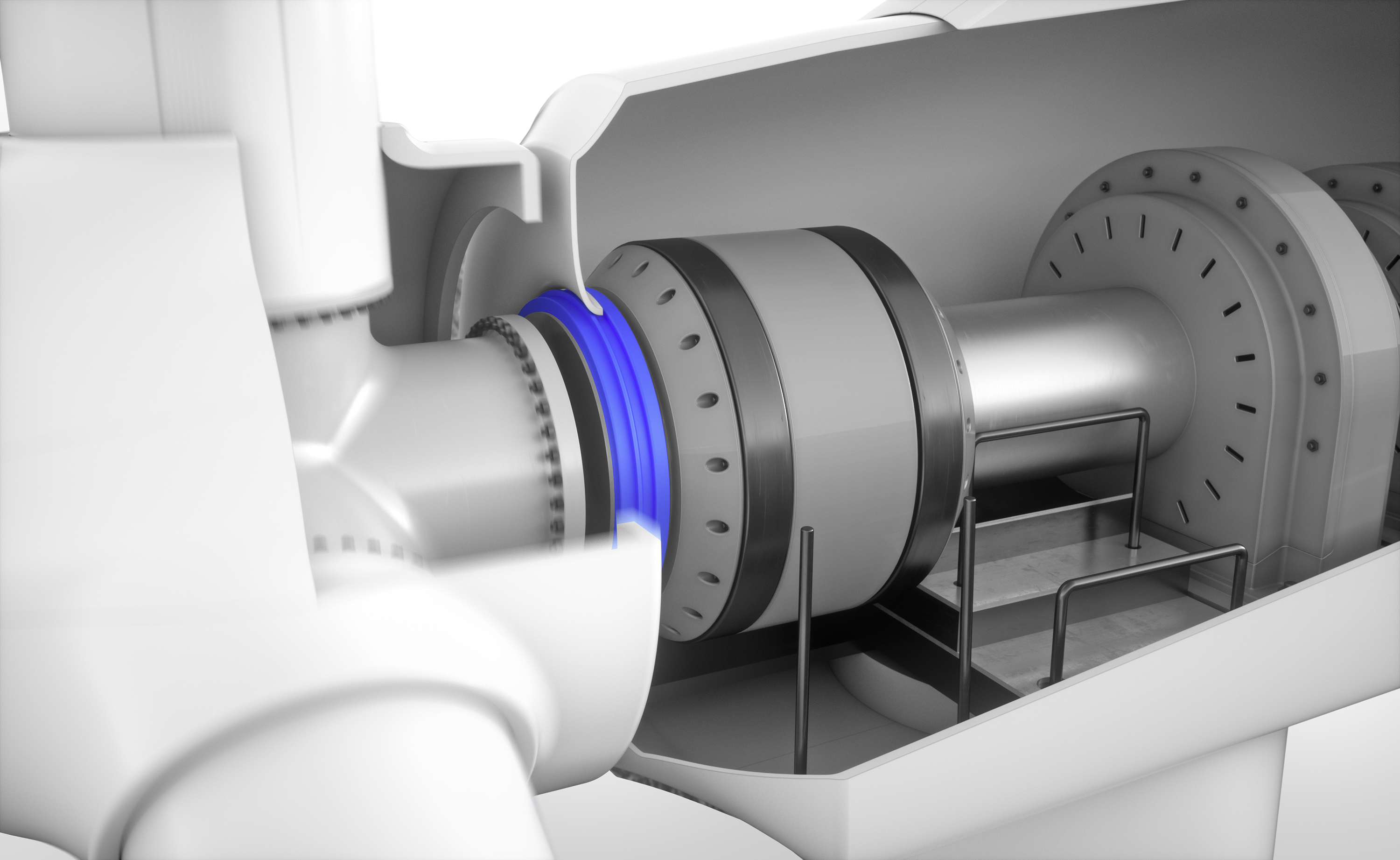

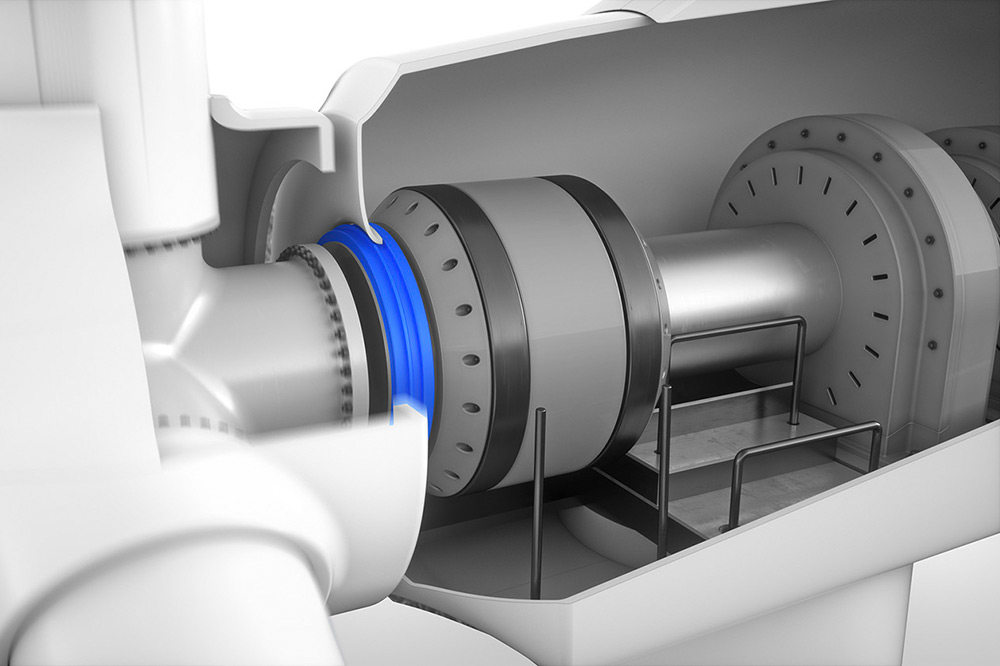

Weinheim (Germany), July 18, 2017. The global expansion of wind power facilities is proceeding unabated. Based on figures from Global Wind Energy Council, nearly 487 GW of output from wind energy were in place at the end of 2016. At the start of the decade, the installed output wasn’t even half that amount. It is not just the number of facilities that has risen sharply – output has climbed as well, especially for wind turbines offshore. But the longer rotor blades that they require lead to higher loads on the main bearing and the shaft. The results are more extensive deformation of these machine elements and greater shaft runout, also known as eccentricity. That’s why Freudenberg Sealing Technologies is developing new seals for current and future wind power facilities. The new generation of radial shaft seal rings has the capacity to follow relatively severe deformations of main bearings and shafts, basically by providing stronger compensating movements. They have also been especially adapted to grease-lubricated systems and thus clear the way for wind turbine manufacturers to use new designs, such as externally rotating main bearings.

The most important task of the Merkel® Radiamatic radial shaft seal ring is to seal the main bearing of wind turbines. This means holding the lubricant within the main bearing and keeping dirt particles and moisture out of the interior of the machine elements needing protection. The tried-and-tested Merkel® Radiamatic seals in use today consist of a fabric-reinforced carrier, a diaphragm and a wedge-shaped seal lip. With the help of a worm spring resembling the tension spring of a desk lamp, the seal lip is maintained under tension. This ensures the continued contact of the seal lip on the shaft.

For the new generation of radial shaft seal rings, Freudenberg Sealing Technologies’ engineers have developed an innovative, robustly configured seal lip design. Together with the carrier, a lean, elongated seal lip creates a V-form. A curved steel band strengthens the seal lip and carrier. In this way, the seal lip acts as a pressure spring. It “presses” onto the shaft on its own, without needing to be fixed by a worm spring. Even at relatively strong shaft runout, the seal lip securely abuts the shaft. In this way, it can fulfil its sealing function even at significantly higher loads on the bearing and the shaft. The steel band is also an integral component of the seal. So in the entire system, the new radial shaft seal ring is just one component that simplifies installation.

Another focus of the developers at Freudenberg Sealing Technologies is the reduction of friction to achieve greater wind turbine efficiency. The long and narrow shape of the new seal lip leads it to abut the shaft with just the width of a hair, even at two-to-three times the usual shaft runout today. Very little friction occurs as a result.

It also acts as a wiper for grease, which is the most common lubricant. With every rotation of the main shaft, it conveys the lubricating grease back into the interior, contributing to still more reduction of frictional losses. “The goal of this development is to bring the tribological system of the shaft, lubricating grease and seal into harmony,” said Dr. Kristian Müller-Niehuus, Development Manager at the Lead Center Heavy Industries at Freudenberg Sealing Technologies.

Since the seal lip of the new radial shaft seal ring from Freudenberg Sealing Technologies lies against the shaft on its own, it is also possible to vary the seal’s direction of force at will. Its spring action can act outwardly as well as inwardly. That gives the developers of wind power facilities and their components new design freedom.

“We had extraordinarily good results in the test bay," Müller-Niehuus said. “That’s why we are taking the next step and testing the new generation of radial shaft seal rings with our customers, the manufacturers of wind power facilities and their components.” With the innovation, which is suited for all bearing and shaft diameters, Freudenberg Sealing Technologies will make reliable, robust sealing concepts possible to meet future requirements in wind power facilities.

Ulrike Reich

Head of Media Relations & Internal Communications

Telephone: + 49 (0) 6201 960 5713

ulrike.reich@fst.com chevron_rightNews Service

You can subscribe to the Freudenberg Sealing Technologies news alert service, bringing you the news as soon as they are published. You can always unsubscribe from this service.

Subscribe now! chevron_rightMore news on the subject Technology & Innovation

First Hand News

Best of all, keep up with the latest developments

with the Freudenberg Sealing Technologies newsletter.