Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

15.05.2017 | Press release

Greater efficiency, lower emissions remain central to Freudenberg product portfolio

Plymouth, Mich., May 15, 2017. As Freudenberg responds to a sea change of new driveline and transmission technologies that include nine- and 10-speed transmissions, vehicle electrification and alternate fuel systems, helping customers achieve greater efficiency and lower emissions remains the focus of its innovation efforts.

At the 11th International CTI Symposium USA Automotive Transmissions, HEV and EV Drives in Novi, Mich., the company will preview some of its newest seal and accumulator innovations during conference speeches and at its booth. These product and process innovations are engineered to help customers reduce transmission friction, incorporate lightweight materials into their vehicle designs, handle smaller, more challenging installation spaces and improve overall fuel economy.

“The automotive industry is on the cusp of historic changes when it comes to transmission and driveline technologies,” said Michael Tercheck, Global Market Segment Manager, Freudenberg-NOK Sealing Technologies. Freudenberg-NOK runs the business operations for Freudenberg Sealing Technologies in the Americas. “Freudenberg’s material, testing and design expertise facilitates the development of advanced vehicle solutions that leverage existing and new systems.

“As discussed at the 10th CTI Symposium last year, the engine is no longer the center of the vehicle,” he continued. “Previously, engines determined what type of transmission and electrification you could get. Now the vehicle’s electrification strategy is driving what kind of engine and transmission you get.”

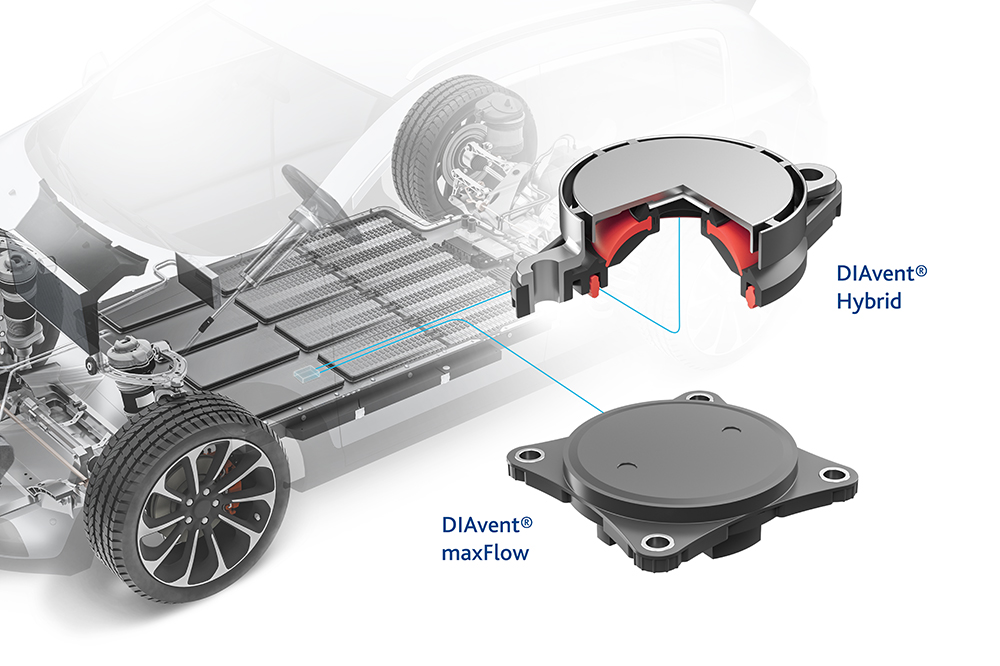

Freudenberg’s award winning Low Emission Sealing Solution (LESS) portfolio of engine, transmission and E-Mobility product solutions have been designed to help the industry achieve more eco-friendly cars and trucks. LESS products include a variety of seals, gaskets, encoders, accumulators, sealing modules and lightweight housings.

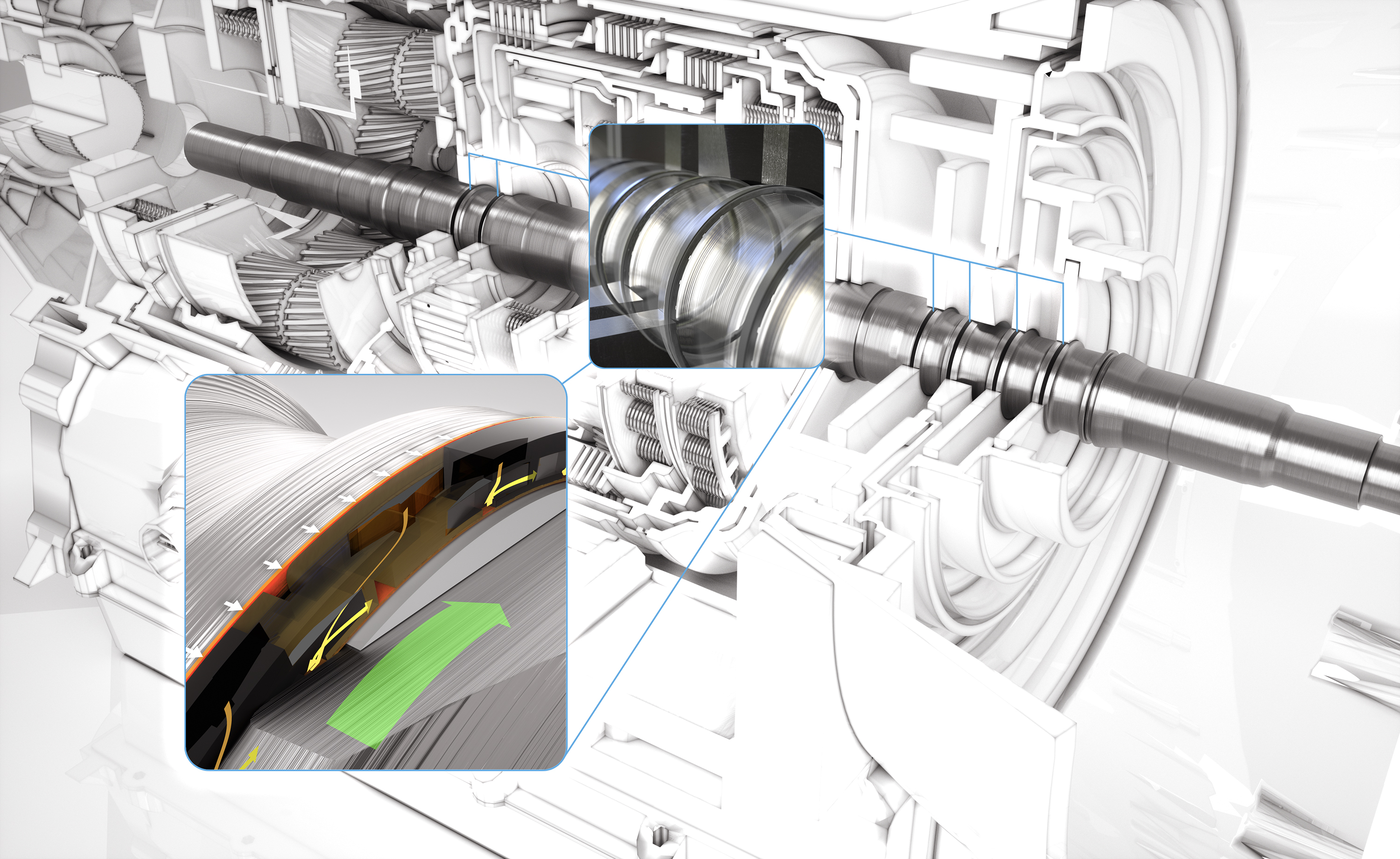

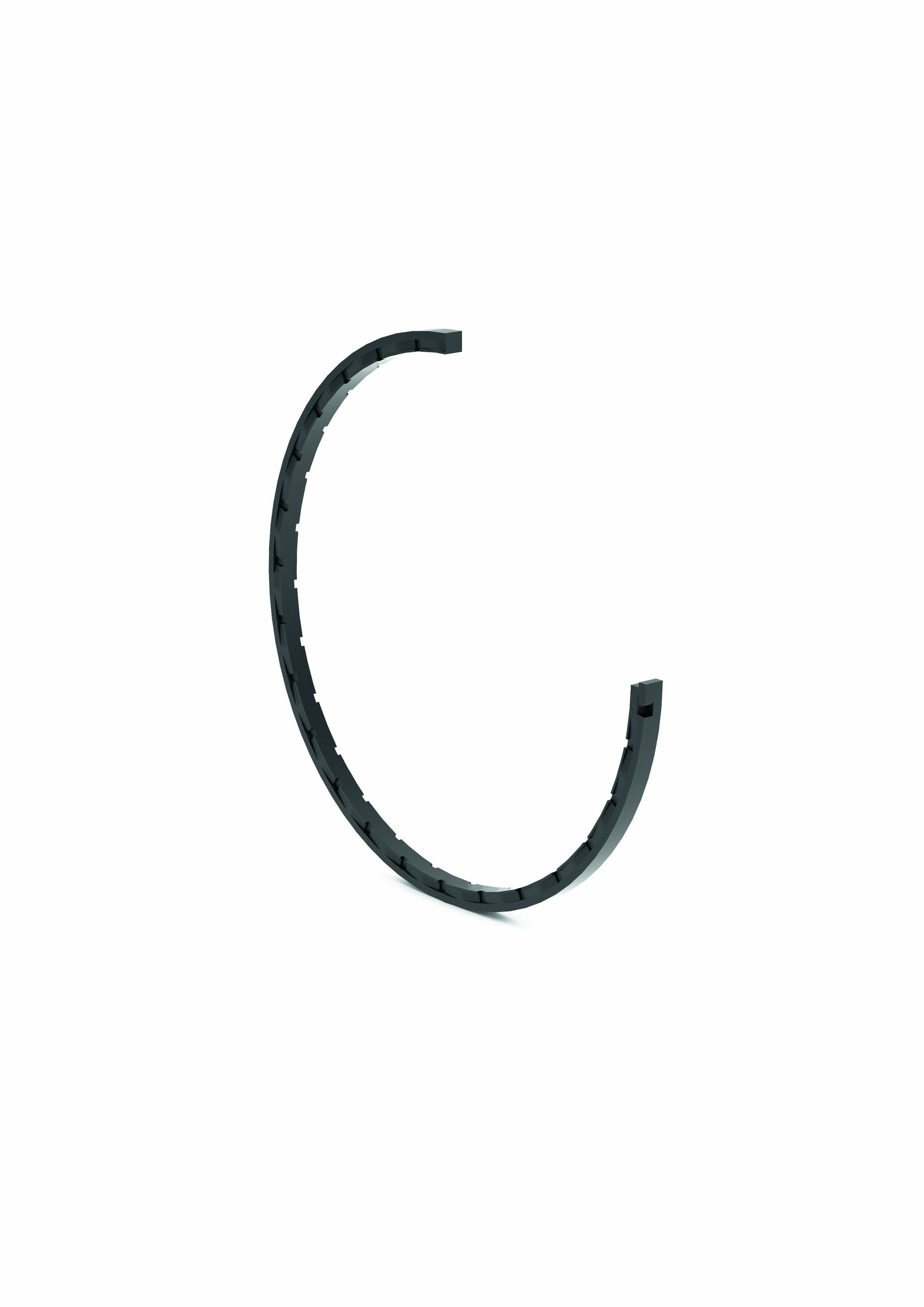

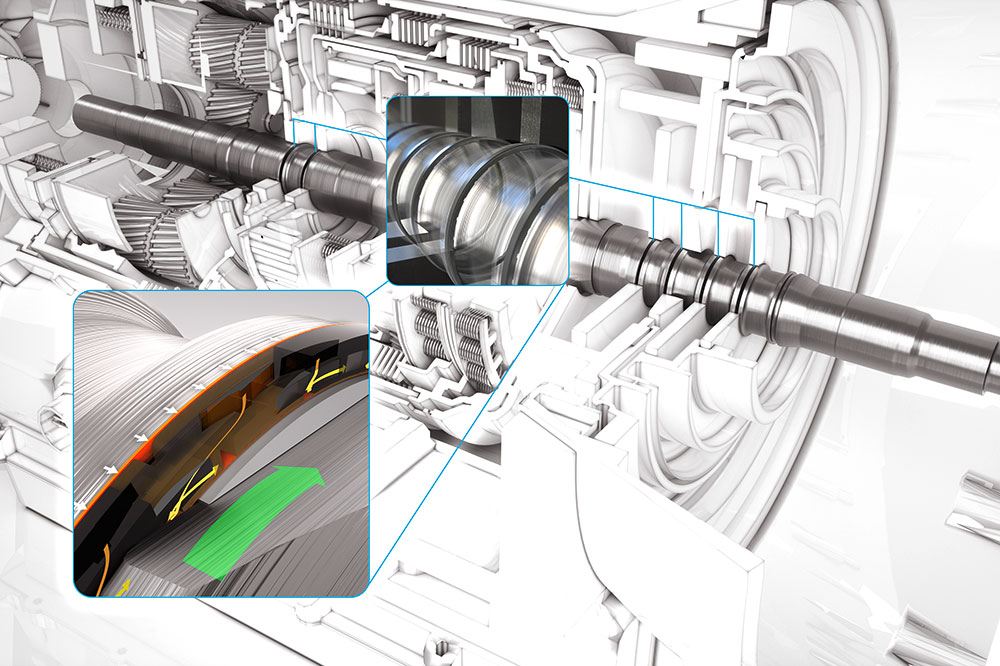

Founded on its flagship gas-lubricated mechanical face seal Levitex® -- which cuts friction by 90 percent and lowers CO2 emissions by up to 1 g of CO2 per kilometer during driving – the LESS portfolio has been recently expanded to include the Levitas low torque seal ring and the Levitorq thrust washer. These sealing options both rely upon hydrodynamic oil film technology to reduce transmission and driveline friction.

Levitas seal rings are suited for installation in many forms of automated transmissions and driveline applications. A special seal design produces a hydrodynamic oil film between the seal ring and its dynamic counter surface. This reduces friction by replacing conventional seal rings in a driveline system. During operation, the seal floats on a hydrodynamic oil film that it generates itself. The film eliminates physical contact between the shaft and the seal ring so that only fluid friction remains and torque levels drop by as much as 70 percent. Levitas seal rings reduce friction and wear to an absolute minimum resulting in significant reductions of CO2 emissions.

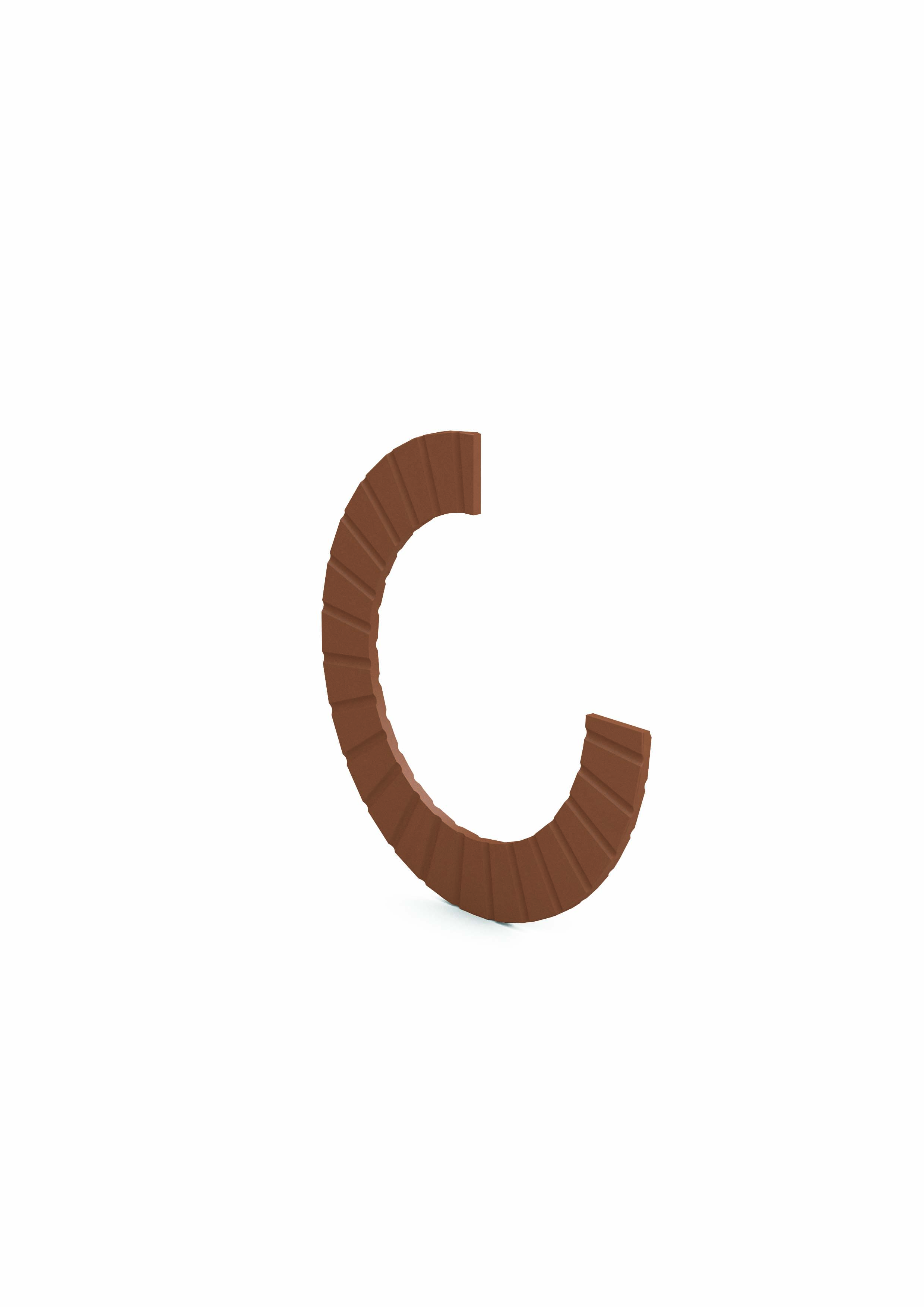

Freudenberg’s Levitorq thrust washer, which also relies on the principles of hydrodynamic oil film technology, is designed to create a surface on which a bearing can roll, or a load can be applied. Traditionally, thrust washers are made from metals, but Freudenberg has used its material expertise and design knowledge, along with proprietary software and testing capabilities, to develop thermoplastic or thermoset alternatives that allow engineers to replace heavy, torque robbing, metal thrust washers. These innovative products help reduce weight, decrease friction, and improve thickness/ flatness control. More information on Freudenberg’s LESS portfolio is available at less.fst.com.

Freudenberg will also preview its newest lightweight piston accumulator technology at the CTI conference. Freudenberg’s new designs and joining methods have substantially reduced the weight of low- and high-pressure hydraulic piston accumulator systems while increasing their efficiency. The company’s new steel high-pressure accumulator saves weight through the use of pressure-optimized, dome-shaped end caps, aluminum pistons as a media separator and a reduction in the thickness of the pressure hull material. Connections between the cap and housing are carried out with electron beam welding.

Likewise, Freudenberg’s new low-pressure accumulator uses an aluminum housing, end caps and pistons to reduce weight. A firmly bonded connection is achieved through electromagnetic pulse technology (EMPT), which is based on the contactless forming of electrically conductive materials with strong magnetic fields. Unlike mechanical crimping, EMPT results in no tool wear, lower contamination, higher stability and consistent system replication. Special low-friction sealing systems are used in both of these hydraulic accumulators, resulting in better system efficiency and hysteresis.

Freudenberg experts will discuss these technologies during two technical presentations at the CTI Symposium. Ray Szparagowski, Engineering Fellow at Freudenberg-NOK Sealing Technologies, will discuss transmission and driveline friction challenges and Freudenberg’s Levitas technology. Thorsten Hillesheim, Technology Director at Freudenberg Sealing Technologies, will introduce lightweight piston accumulator technology for hydraulic hybrid drive systems.

Press Release Downloads

Greater efficiency, lower emissions remain central to Freudenberg product portfolio

Last update: 15.05.2017

English | PDF | 159 KB

DownloadNews Service

You can subscribe to the Freudenberg Sealing Technologies news alert service, bringing you the news as soon as they are published. You can always unsubscribe from this service.

Subscribe now! chevron_rightMore news on the subject Technology & Innovation

First Hand News

Best of all, keep up with the latest developments

with the Freudenberg Sealing Technologies newsletter.