Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

27.06.2017

Protection for the Heart of the Electric Car: Battery seals from Freudenberg

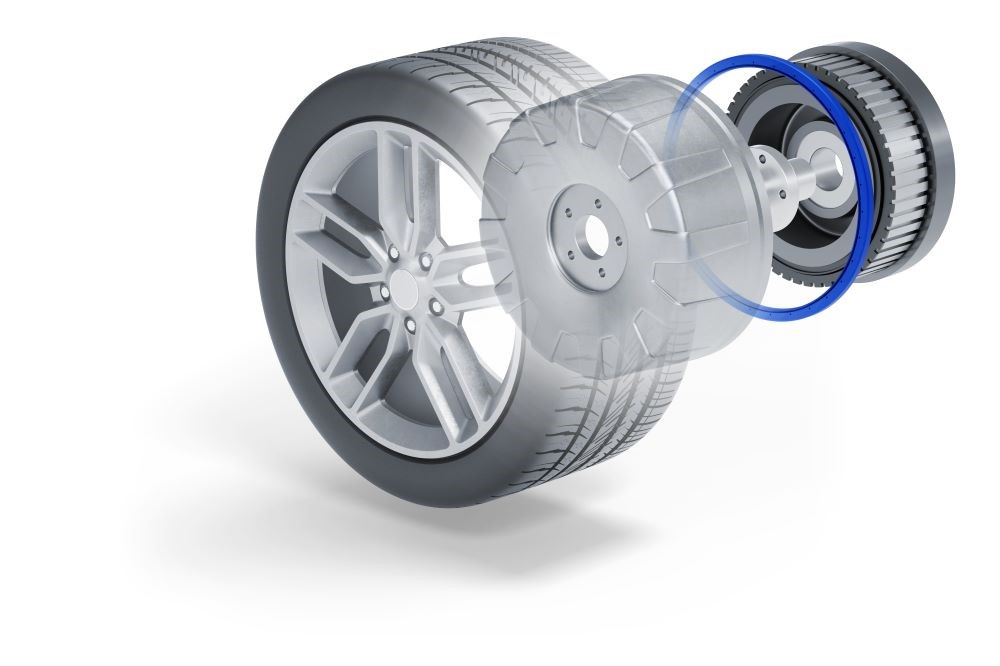

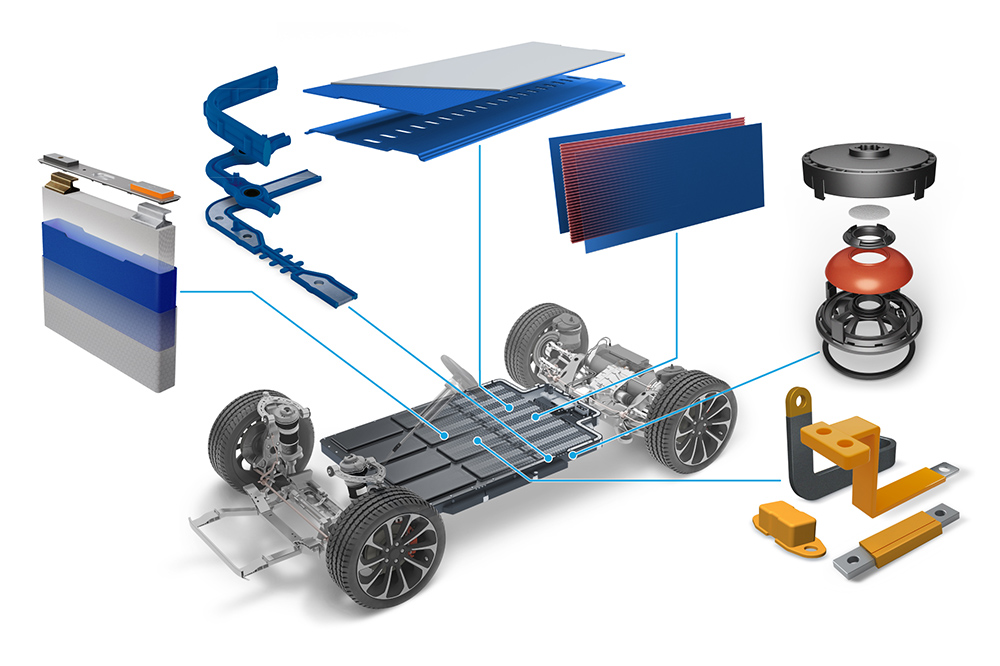

The traction battery is the core of an electric vehicle. In all circumstances, it is essential to protect its high-voltage components from moisture and dirt, even in long-term operation. At the same time, it must be possible to open battery housings for maintenance. That’s why automakers are turning to housings with a large cover that allows good access to all components. Freudenberg Sealing Technologies offers profiled flat gaskets to guarantee complete impermeability when the cover is closed.

Lithium-ion batteries equipped in this way have proven themselves in the Renault Zoe, for example. But the cross-section and dimensions of such seals must be adapted exactly to a specific battery. Changes are impossible without fabricating a new tool. The investment in a tool of this kind mainly repays the expense at higher volumes. As a result, straight sealing profiles come into use for very small production runs, such as the manufacture of prototypes. Their lengths can be cut manually. They are connected to one another using special corner pieces, making it possible to cover any housing geometry. “Both concepts have proven themselves in the market,” said battery expert Dr. Peter Kritzer of Freudenberg Sealing Technologies. “But we deliberately sought another solution for the medium-range volumes that prevail in the market for electric vehicles today.”

With the “Profile-to-Gasket,” or “P2G,” concept, a solution meeting these needs has recently become available. This new housing seal is based on a simple principle: The two basic functions of “sealing” and “fixing” are achieved in separate parts of the sealing profile. In this way, a compressible hollow profile on the outer side of the seal – which can be up to 15 mm wide – makes certain that no fluids or particles penetrate into the housing. This hollow profile also guarantees the tolerance compensation required in a housing seal. On the inner side, there is a fixation strip that can attach the seal to the housing. The design makes it possible to manufacture the P2G seal as an endless band and trim it to the required length in each case. With targeted incisions in the attachment area, it is possible to guide the seal in tight radii around corners. Both concave and convex radii can be achieved. “We can cover any given geometry with this solution,” Kritzer said. Another advantage of the endless profile is that it can securely seal even very large battery housings – an important feature in view of the trend toward greater ranges. The hollow profile promotes this characteristic. By screwing down the housing and cover, the profile is compressed to a height of about 1.5 mm, whereby the fixation strips function as an end block while balancing out potential production tolerances. The low tensile stresses that emerge in the installed state ensure a high degree of mechanical tightness even during the housing’s torsions during driving.

Earlier this year, Freudenberg Sealing Technologies received the European patent 2634457 B1, for this product. The customer now has a choice. The P2G seal can basically be sourced as endless goods. The seal manufacturer also has the capacity to provide car and battery manufacturers with made-to-order individual seals equipped with a fastener. Freudenberg Sealing Technologies is now looking into how much the tailoring process can be automated. “That would also open the door to larger volumes,” Kritzer said.

The battery experts at Freudenberg Sealing Technologies are not just focused on sealing housings. For example, sealing components are important for the cooling circuits of the new battery generations as well. "Future generations of batteries will be distinguished by both their high energy density and their capacity to charge large amounts of energy in a very short time,” Kritzer said. “Liquid-cooled batteries are catching on in the market as a way to draw off the heat that builds up during operation – and especially during charging.” With its expertise, Freudenberg Sealing Technologies intends to play a role wherever new solutions for battery thermal management are being considered.

Ulrike Reich

Head of Media Relations & Internal Communications

Telephone: + 49 (0) 6201 960 5713

ulrike.reich@fst.com chevron_rightDownload Documents

Download Images

News Service

You can subscribe to the Freudenberg Sealing Technologies news alert service, bringing you the news as soon as they are published. You can always unsubscribe from this service.

Subscribe now! chevron_rightFurther Articles With These Taggings

First Hand News

Best of all, keep up with the latest developments

with the Freudenberg Sealing Technologies newsletter.