Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

06.12.2017 | Press release

High Temp Rubber Gasket, Fluorinated Rubber Offers Excellent Sealability

Plymouth (USA), December 6, 2017. Global automotive standards calling for higher fuel economy and lower emissions during the next decade continue to drive substantial changes in the industry. Vehicle manufacturers are pursuing a range of powertrain responses including electric drivetrains, hydrogen fuel cells, nine- and 10-speed transmissions and smaller, more powerful, turbocharged engines. At the heart of these technologies are seals that will continuously function in environments that operate under higher temperatures and pressures with new lubricants in tighter installation spaces.

Freudenberg-NOK Sealing Technologies, a global leader in the development of engineered elastomers, has introduced a new family of proprietary fluorinated rubber to meet static seal challenges. The materials offer excellent sealing capabilities under very high temperatures and pressures, ease installation challenges and are cost competitive against more expensive perfluorinated material options. The new rubber can also be custom mixed to meet specific powertrain engineering requirements.

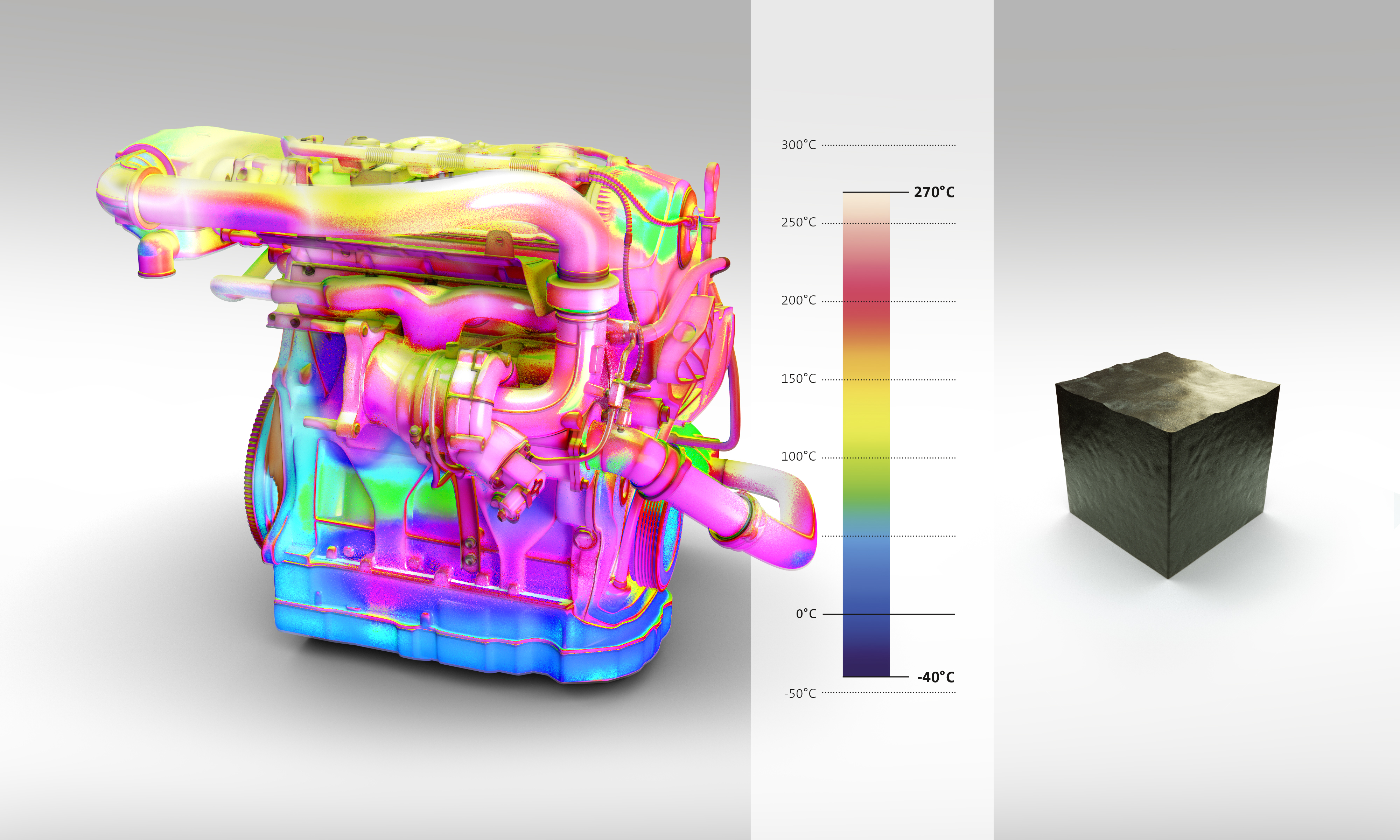

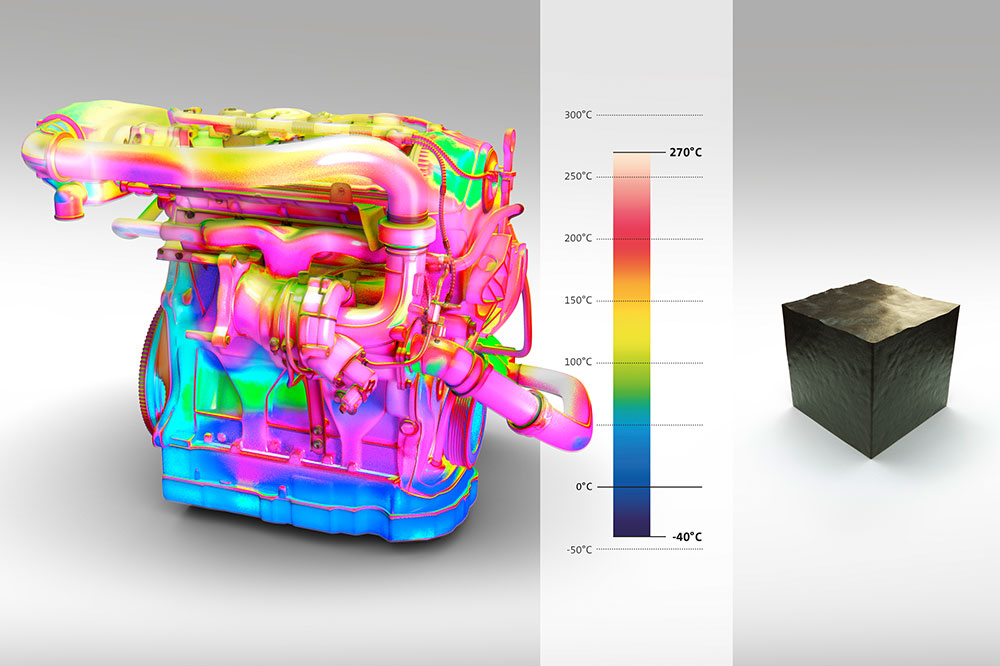

Freudenberg-NOK, which runs the business operations for global seal manufacturer Freudenberg Sealing Technologies in the Americas, has had the new fluorinated materials under development for the past four years. Unlike traditional fluorocarbon rubber, which effectively handles temperatures ranging from -40° to+235°C, the new formulas effectively seal at temperatures ranging as high as 270°C.

In addition, Compression Stress Relaxation (CSR) testing performed by Freudenberg-NOK on the high temperature fluorinated materials demonstrated exceptional sealing capability. The elasticity of these materials is maintained along with their flexibility after prolonged high temperature air exposure. Extensive laboratory analysis shows that the chemical resistance for which fluorinated rubber is known and used remains uncompromised.

“We know our customers are being challenged on multiple fronts to develop innovative vehicle system solutions, and we are working with them to meet these challenges through the development of new materials and compounds,” said F. Joseph Walker, Global Technology Director, Materials and Laboratory Services for Freudenberg-NOK Sealing Technologies. “This new family of fluorinated rubber materials, for example, is especially suitable to the high heat, high pressure, static seal environment associated with turbocharging.”

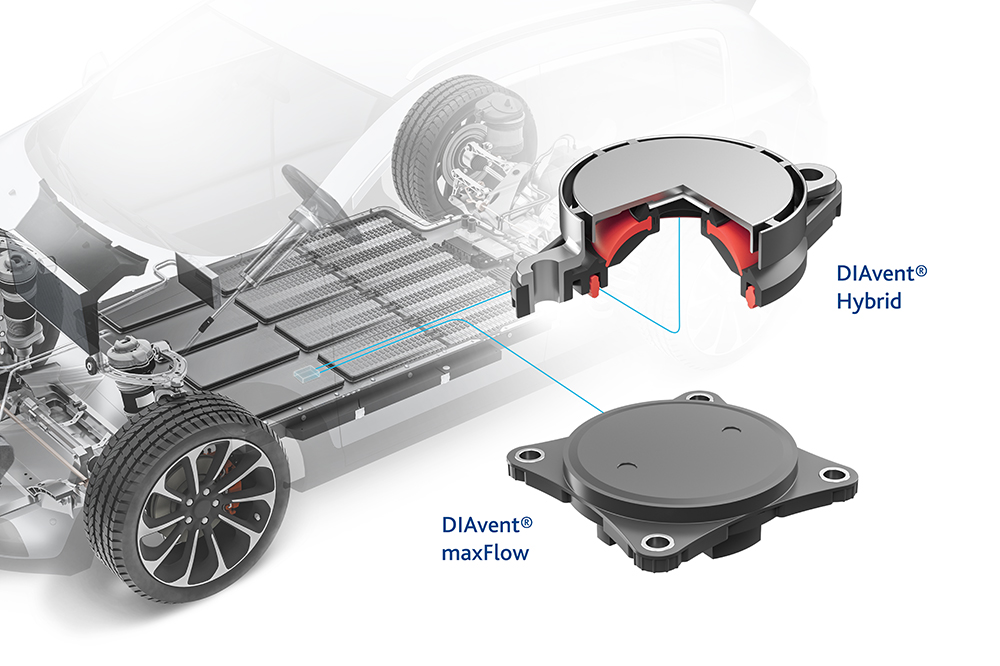

Elastomeric seals are essential to the efficiency of all powertrain technologies. Freudenberg Sealing Technologies is focused on developing effective sealing solutions for new technologies like electric vehicle systems and fuel cells as well as new internal combustion engine designs. During a recent industry conference, the company introduced a portfolio of unique smart materials that combine different properties to achieve sensor and actuator functions in seals. The company’s state-of-the-art material testing and analysis further assures customers that its component solutions function in real world systems where fluids, pressures, temperatures and designs vary widely by model, manufacturer and region.

News Service

You can subscribe to the Freudenberg Sealing Technologies news alert service, bringing you the news as soon as they are published. You can always unsubscribe from this service.

Subscribe now! chevron_rightMore news on the subject Technology & Innovation

First Hand News

Best of all, keep up with the latest developments

with the Freudenberg Sealing Technologies newsletter.