Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

12.09.2017 | Press release

Ready for the Mobility of the Future

Weinheim (Germany), September 12, 2017. Electric mobility is one of the most important themes for the future at the IAA 2017, which opens its doors this week in Frankfurt (Germany). Whether the topic is electric cars or new trends in service or infrastructure, the range of issues related to e-mobility is enormous. And they are bringing lasting changes to the auto industry. The key is to master the basic technological change, from the internal combustion engine to emission-free mobility. This applies to suppliers such as seal manufacturer Freudenberg Sealing Technologies as well.

“On one hand, our current challenge is to make classic internal combustion engines more efficient with innovative solutions, since they will be with us for years to come,” said Claus Möhlenkamp, CEO of Freudenberg Sealing Technologies. “But, at the same time, we are going all out to develop components for new powertrain technologies and thus shape the mobility of the future.”

Both the internal combustion engine and electrified powertrains will have an impact on the automotive market, experts agree. “We also expect that global markets will move at very different speeds and take different technological paths,” Möhlenkamp said. But one thing is certain: In the mobility of tomorrow, the classic internal combustion engine will play a less important role than it does today. Studies assume that its share of the European and North American markets will be about 30 percent by 2030.

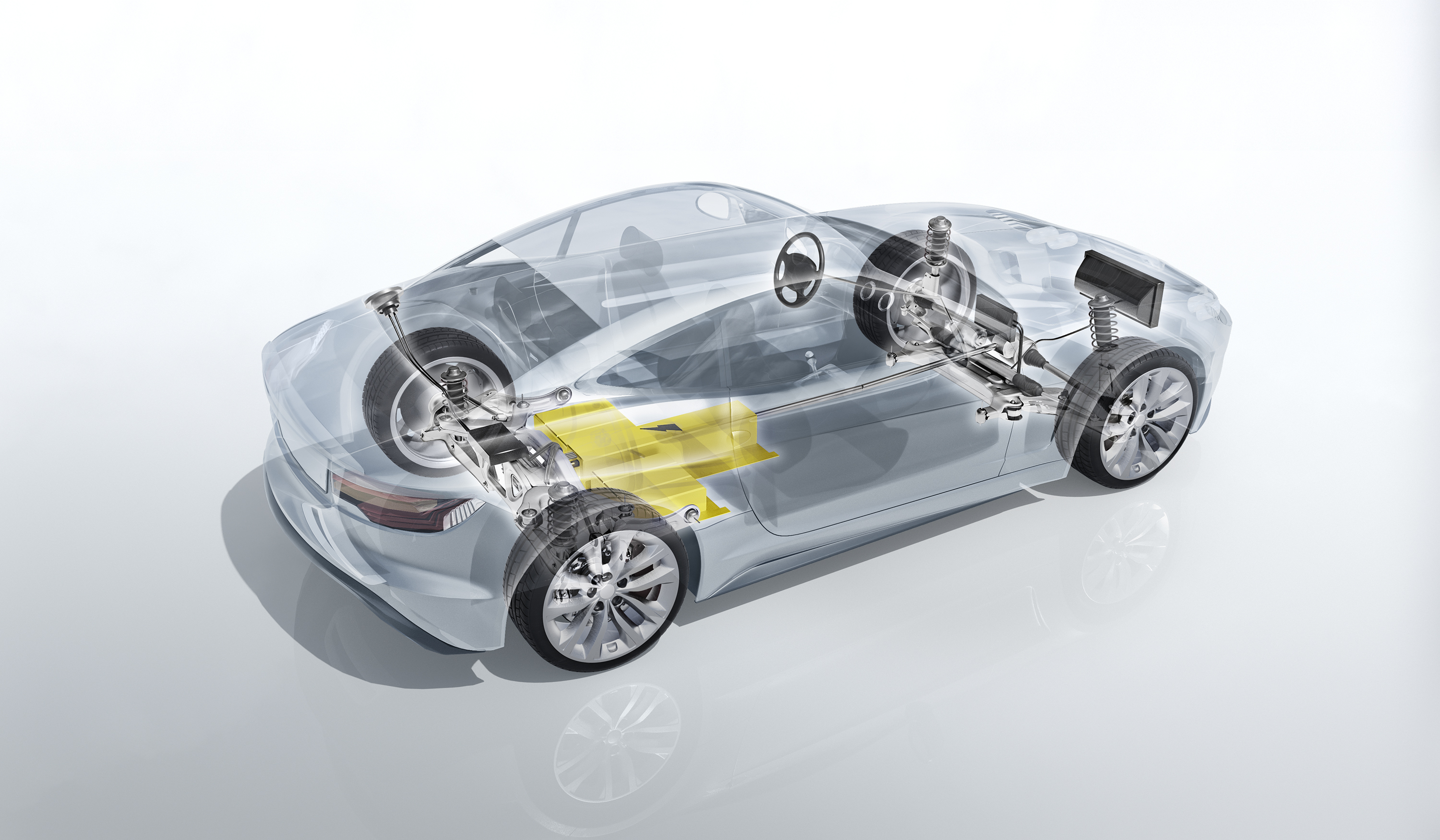

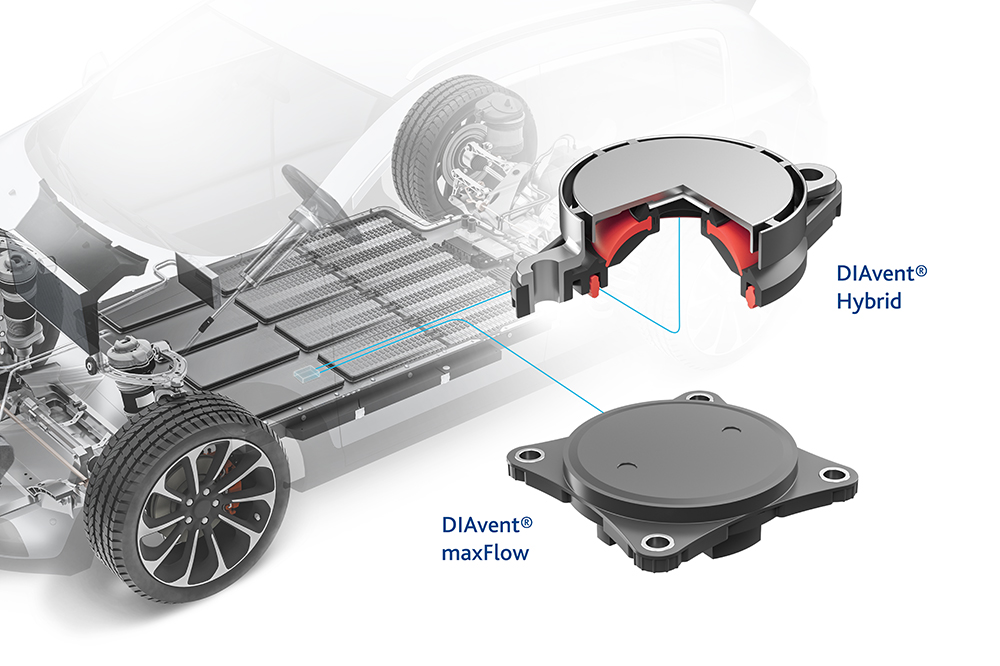

With this in mind, Freudenberg Sealing Technologies is hard at work on the development of sealing innovations for electric vehicles. The focus is on batteries since they are the heart of the new powertrains, whether they are fully electric or plug-ins. In recent decades, the company has gained considerable expertise in battery safety and thermal management. For example, its sealing experts have come up with a new housing seal that optimizes pressure compensation, an important issue for electric mobility. Freudenberg Sealing Technologies is helping to make the production of electric cars more economical in relatively small volumes with another innovative seal for the housings of traction batteries. The patented “Profile to Gasket” concept, or P2G, was developed especially for volumes up to 5,000 batteries annually. It complements the seals that have been available to this point, which are primarily designed for high-volume production. Batteries with high power densities and the associated need for cooling require flat seals or Plug & Seals, which Freudenberg Sealing Technologies also manufactures.

For its electric-mobility products, the company is also emphasizing thermal management and two-component housings for sensors and other electronic components. Another promising field is lightweight construction, with plastics that insulate or conduct heat or electricity. Mechanical face seals are also needed in electric motors, and Simmerring® shaft seals remain indispensable in the transmissions of electrically-powered vehicles. Finally, the housings for sophisticated control electronics must be sealed. “Our long-term goal is to provide made-to-order products for nearly all the components of an electric vehicle,” Möhlenkamp said.

Freudenberg sealing experts are simultaneously striving to make classic internal combustion engines more efficient with emission-reducing products. In its LESS (Low Emission Sealing Solutions) portfolio, the company bundles innovative sealing solutions that help to minimize friction, optimize the combustion process, save weight and, in the process, reduce energy consumption and emissions sustainably. The political pressure to reduce emissions is still a reality, and the company takes it very seriously, Möhlenkamp said. "With our LESS products, we are helping our customers achieve their emission goals – for conventional engines as well as electrified powertrains.”

The gas-lubricated mechanical face seal Levitex is one highlight in the Freudenberg lineup of friction- and emissions-reducing products. It decreases CO2 emissions by up to 1 gram of CO2 per kilometer driven. Long operating lives become possible due to the reduction in wear. With the seal's greater pressure stability, totally new directions in engine development are opening up.

The focus is also on emissions reduction in transmission development. That’s why Freudenberg has developed the sealing ring Levitas for rotary feedthroughs in transmissions. It “floats” on a hydrodynamic oil film that it generates itself, reducing wear to an absolute minimum. This leads to a considerable reduction in CO2 emissions. Even when there is no physical contact between the seal ring and shaft, the sealing function is completely guaranteed.

More information on Freudenberg Sealing Technologies activities in electric mobility can be found here. Details on the LESS portfolio are available at less.fst.com.

Ulrike Reich

Head of Media Relations & Internal Communications

Telephone: + 49 (0) 6201 960 5713

ulrike.reich@fst.com chevron_rightNews Service

You can subscribe to the Freudenberg Sealing Technologies news alert service, bringing you the news as soon as they are published. You can always unsubscribe from this service.

Subscribe now! chevron_rightMore news on the subject Technology & Innovation

First Hand News

Best of all, keep up with the latest developments

with the Freudenberg Sealing Technologies newsletter.