Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

28.04.2017 | Press release

“Electric Mobility Offers New Opportunities Every Day”

In an interview, Claus Möhlenkamp, CEO of Freudenberg Sealing Technologies, explains how the sealing specialist is adapting to the auto industry’s looming transformation.

Electric mobility is increasingly becoming a reality. Who is dealing with this issue at Freudenberg Sealing Technologies?

At our company, electric mobility is an issue for the top leadership. It is imperative to seize the opportunities being offered. In recent years, Freudenberg Sealing Technologies has greatly benefited from the fact that internal combustion engines have had to function more and more efficiently. Now we have to position ourselves for the new business in time. That’s why we recently formed a special department for application development and sales, which deals exclusively with electric mobility.

How are you responding to the new demands? What applications do you see in electric mobility?

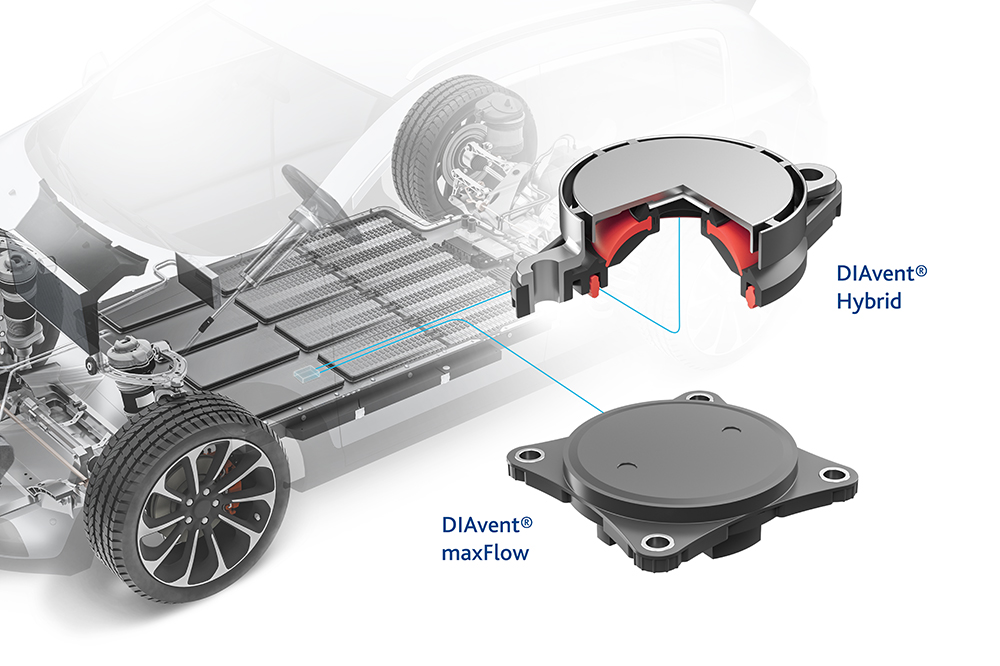

On the product level, for example, we are putting our emphases on thermal management and two-component housings for sensors and other electronic components. Another promising area is the lightweight construction of electrically powered vehicles with electric- and heat-insulating – or alternatively conductive – plastics for electric motors. Batteries with a high power density and the corresponding need for cooling require flat seals or Plug & Seals. Mechanical seals are needed for electric motors, and Simmerrings remain indispensable for the transmissions of electrically-driven vehicles. Finally, the housings for sophisticated control electronics must be sealed. Our goal: We want to provide made-to-order products for nearly all the components of an electrical vehicle.

How quickly will the shift from the combustion engine to electric drive take place?

The auto industry is facing a fundamental technological shift from the internal combustion engine to emission-free mobility. Exact predictions about production figures are always fraught with uncertainties. But we are assuming electric vehicles will reach significant volumes after 2025. At the same time, the number of combustion engines will increase further as the global automotive market grows. Between 2025 and 2035, according to our estimates, the production of classic combustion engines will reach its peak and then gradually subside.

What is your assumption based on?

There are several factors that suggest that the electric powertrain will prevail long-term. For example, there is the societal shift calling for emission-free driving in city centers. Automakers have already responded and are investing substantial resources in the development of electric vehicles and powertrains. As a result, battery technology is continuing to develop rapidly. The familiar hurdles facing battery-powered electric vehicles such as energy density, range and charging speeds, along with costs that are still too high, can be overcome with systematic research and development.

Are you now focusing your R&D activities on electric powertrains?

The trick is to do both: On one hand, continue to develop the classic business and make combustion engines more efficient. On the other hand, make sufficient resources available to develop components for new powertrains. We cannot completely lose sight of conventional powertrains. They will still be with us for some time worldwide. New ideas are needed for them as well. Our LESS portfolio (Low Emission Sealing Solutions) will continue to play a major role in this area. The political pressure to reduce emissions is still a reality. We are helping customers to reach their emissions goals. We want to defend our market share with innovative products in conventional powertrain technology as well, and expand it wherever possible. Incidentally, greater efficiency through low-friction and lightweight components is at least as important to an electric vehicle as it is to a car with a combustion engine.

But does an electric vehicle require just as many high-quality seals as a car with a combustion engine?

For one thing, in the next decade, we will see a great many plug-in hybrids that have an electric powertrain as well as a combustion engine. That will boost the number of the seals in the vehicle and their total value. And we have already developed solutions for the electric side, such as frame seals for batteries. But in the transition to purely electric, battery-powered powertrains, our supplier share will decline if we do not seize the new opportunities that are emerging from electric mobility.

Where do you see them?

The trend to the electric powertrain offers us new opportunities almost daily. For example, we are currently deeply involved with thermal management. Keeping the battery within an optimal temperature range becomes all the more important the more output density and charging speeds increase. But we are thinking even further ahead. Our materials expertise in polymers is an excellent starting point for identifying solutions to many emerging problems. Let’s take thermally conductive plastics for a moment: They are making lightweight construction possible since they could displace metals today in some applications.

How does the issue of battery cooling proceed specifically?

It has always been important for us to jointly develop ideas with the customer. At the moment, we are seeing a great deal of encouragement to develop further in the direction of thermal management. That will take staying power, but we have demonstrated it in the past. It took more than 10 years to go from the first idea for a gas-lubricated crankshaft seal to the regular production launch of Levitex.

It sounds a little as though your core product, the seal, would become less important in the future.

Our seal know-how is – and will continue to be – the core of our business. But we have been expanding our portfolio for a long time. For example, with the acquisition of the Schneegans Group, we have created the precondition for offering lightweight plastic components with an integrated seal. And we are definitely open to moving from being a component manufacturer toward modules or even systems. In the process, it is important to me that we maintain our high level of added value. It is now more than 70 percent and should not fall below 50 percent.

What role is the fuel cell playing for the mobility of the future?

If you take a very long-term perspective – roughly looking ahead to the year 2050 – then you presumably have to realize that the internal combustion engine will have run its course for mobile applications. The efficiency of its energy chain is too low for those uses. On the other hand, the battery-powered electric vehicle has very good energy conversion efficiency and can be operated climate-neutrally with renewable energy. When it comes to CO2-neutral long-haul mobility, however, the fuel cell is likely the only option. Moreover, the hydrogen tank for a fuel cell can be filled even in extreme temperatures – battery charging, by contrast, is impossible in freezing Siberian temperatures. In our opinion, the fuel cell has some justification in the powertrain mix of the future

What opportunities does the fuel cell offer Freudenberg Sealing Technologies?

Sealing serves an extremely important, safety-relevant function in hydrogen fuel cells. We began the development of fuel-cell components 15 years ago. In the U.S., we have had the series production of seals used in materials-handling equipment underway since last year. With considerable volumes. But it will probably be a while before we see high-volume production for road vehicles.

Freudenberg Sealing Technologies is not only an automotive supplier – it is an industrial supplier as well. What does the change in vehicle powertrains mean for potential synergies within the company?

The main success factor for us is that we think our way into the particular application and look beyond the seal as structural component. In our production operations, we have so-called “focus factories,” which concentrate either on automotive components in large volumes or our highly specialized industrial business. Nonetheless, the segments benefit from one another when it comes to materials that are exposed to very low and very high temperatures. The same thing applies to resistance to chemically aggressive media – here the automotive area takes advantage of the knowledge that we have acquired in the process industry. We can do fine with the currently small volumes in electric mobility. We owe this not least of all to the fact that we are used to them from our industrial business.

So you don’t see the trend toward electric mobility as a threat?

Over the past 167 years, Freudenberg Group has adapted successfully to changed markets again and again. We have always found new solutions and we have the requisite financial power to finance developments over the long term. So we’re not too worried about the change, which isn’t coming overnight anyway. The crucial factor is that we tackle the new electric mobility issue with enthusiasm – and we'll do that!

Ulrike Reich

Head of Media Relations & Internal Communications

Telephone: + 49 (0) 6201 960 5713

ulrike.reich@fst.com chevron_rightNews Service

You can subscribe to the Freudenberg Sealing Technologies news alert service, bringing you the news as soon as they are published. You can always unsubscribe from this service.

Subscribe now! chevron_rightMore news on the subject Technology & Innovation

First Hand News

Best of all, keep up with the latest developments

with the Freudenberg Sealing Technologies newsletter.