Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

15.06.2017

Freudenberg Expertise, Collaboration Help New Commercial Aircraft Take Flight

Precisely engineered pylon seals, developed by Freudenberg with input from UTC Aerospace Systems, helped the newest member of the Embraer E-Jets E2 program take flight despite a very challenging production schedule. Pylon seals are an integral part of the aircraft’s nacelle thrust reverser system.

Freudenberg will be on hand at next week’s International Paris Air Show to celebrate the appearance of the E195-E2 aircraft at the event and to highlight its extensive portfolio of aerospace products and materials. The company’s project collaboration with UTC Aerospace Systems underscores its ability to analyze challenging aerospace applications and work jointly with customers on unique solutions.

“The success of the recent UTC Aerospace Systems seal program – a program that literally ran against the clock – is testament to how we approach our work on behalf of the industry,” said Paul Hailey, Senior Vice President of Freudenberg’s Global Gaskets Division. “Our employees delivered an advanced sealing solution that not only met critical performance factors but also kept flight testing on track. Collaboration and customer value are essential elements of our business success.”

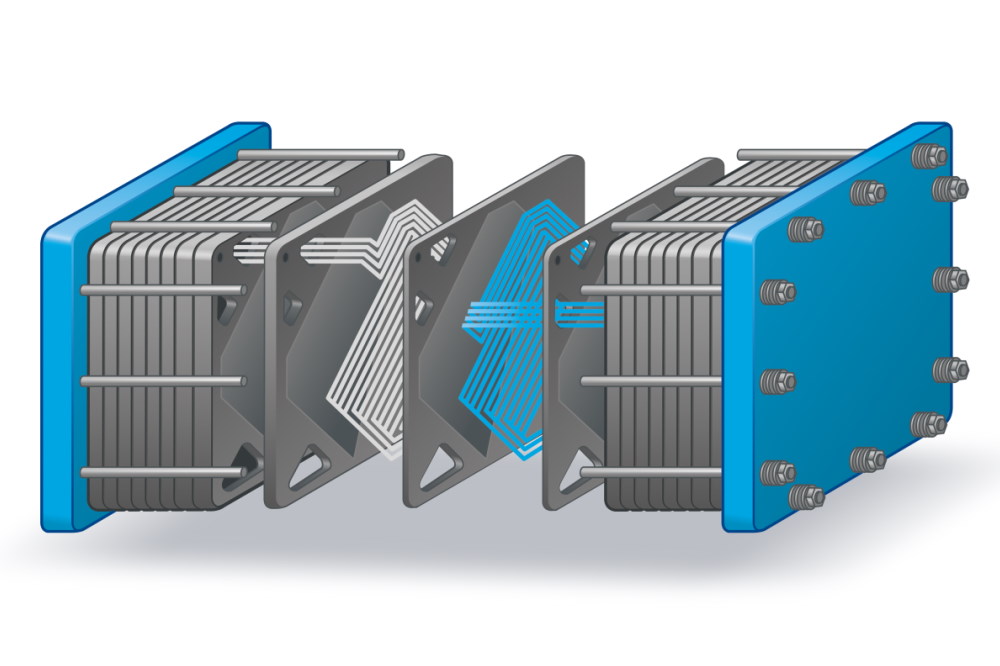

Freudenberg was already providing nacelle and thrust reverser seals for inclusion on the E195-E2 aircraft when UTC Aerospace Systems asked the company to handle development of new pylon seals. The seals had to be delivered in record time and meet rigid “burst duct” conditions involving higher pressures and larger system gaps.

Freudenberg engineers launched seal development in July 2016. Multiple, complex engineering and development studies helped facilitate communications and collaboration with UTC Aerospace Systems in selecting a final component design. Additional efforts from material and tool shop suppliers allowed Freudenberg to manufacture and deliver the seals in January 2017, two months ahead of the originally communicated schedule. Everyone involved in the program worked as a cohesive unit to meet and exceed delivery deadlines.

“Freudenberg’s efforts to expedite the development and manufacturing of this seal helped us deliver UTC Aerospace Systems thrust reversers on time,” said Gary Reynolds, Vice President, Regional and Engine Programs, UTC Aerospace Systems. “It was rewarding to see how the many challenges along the way were overcome through great teamwork and communications.”

Visitors at this year’s Paris Air Show will be able to see a variety of fireproof sealing solutions and other aerospace components from Freudenberg at the company’s booth in Hall 5, #D266. In addition to pylon seals, Freudenberg will showcase:

- O-Rings

- Plate seals and gaskets

- Polytetrafluoroethylene (PTFE) back-up rings and cylinder seals

- Simmerring® radial shaft seals

- Fire seals

- Aerodynamic seals

- Electrical grommets

- Self-fusing silicone tape

- Elastomeric shrouding and ducting.

"Freudenberg offers customers an extensive portfolio of aerospace sealing solutions, and we invite them to our booth to explore technology options," said Sean Morgan, Global Segment Director-Aerospace, for Freudenberg. "Equally important, we offer engineering support and material testing to assist our customers in developing unique solutions to their application requirements."

More information on Freudenberg’s aerospace product portfolio here.

Download Documents

News Service

You can subscribe to the Freudenberg Sealing Technologies news alert service, bringing you the news as soon as they are published. You can always unsubscribe from this service.

Subscribe now! chevron_rightFurther Articles With These Taggings

First Hand News

Best of all, keep up with the latest developments

with the Freudenberg Sealing Technologies newsletter.