Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

28.11.2017

New Seals for Washing Machines with Active Oxygen

For years, washing machine manufacturers have primarily focused on two aspects: first, reducing the use of water and electric power to conserve resources and achieving the highest possible energy efficiency class for the appliances; second, the growth in the target laundry capacity, especially for front loaders. Today, standard European appliances handle between five and eight kilograms of laundry, in the US 12 to 20 pounds. Now a new washing technology is making inroads into households: washing with active oxygen. It is not in the detergent or some additive; it is produced by a generator within the appliance, in order to clean the laundry in supplemental steps before and after the wash cycle. The active oxygen process eliminates bacteria, germs and smells – with this gentle treatment, the laundry also becomes hygienically clean in low temperature washing programs. Delicate textiles can even be refreshed without any water at all with a separate program.

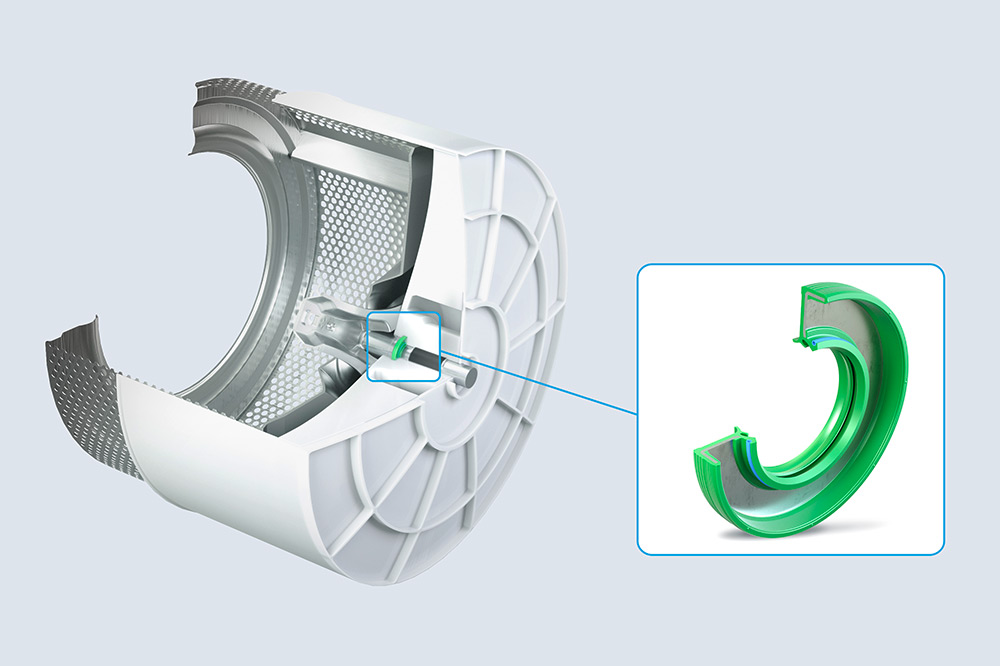

But what’s good for laundry isn’t necessarily good for the appliance’s seals. Active oxygen used in the new process can attack conventional nitrile rubber (NBR) seals so aggressively that cracks -form and the seals lose their functionality within a few hours. The main seal, which seals the driveshaft toward the housing, is especially affected. For one thing, the Simmerring® shaft seal used here must keep soapy water from escaping and damaging the bearing, for example. For another, it must keep the lubricant for the shaft and bearing on the drive side throughout the washing machine’s lifespan. To do this, it must apply the right pressure onto the shaft – but it must be resistant to any medium being used as well.

Experts at Freudenberg Sealing Technologies worked to identify a seal material that could withstand the lubricants and detergents employed to this point, and also withstand the active oxygen now coming into use. The developers identified FKM as a solution – a material with which Freudenberg Sealing Technologies has had decades of experience in other fields, including the auto industry and powertrain technology. But it had not yet been employed in washing machines.

To adapt the FKM material to this appliance application, engineers at Freudenberg Sealing Technologies paid special attention to two areas. First, they developed a new FKM compound with wear behavior optimized for the new application – over its entire operating life, in fact. The second challenge related to FKM’s tendency to swell in damp conditions. That’s why they increased the material’s resistance to the hot water-alkaline mixture in the washing drum. Finally, they adjusted the geometry of the seal lip so the seals made from the new material would exhibit the same mechanical behavior as the NBR Simmerring® shaft seals employed up until then with regard to compression and radial forces, for example.

Freudenberg Sealing Technologies is now preparing for the series production of the main seals in washing machines that use active oxygen. They are a robust solution that needs no additional installation space. In this way, the new seals are enabling the advance of a new washing technology that promises hygienic cleanliness while sparing clothing and the environment.

Ulrike Reich

Head of Media Relations & Internal Communications

Telephone: + 49 (0) 6201 960 5713

ulrike.reich@fst.com chevron_rightDownload Documents

Download Images

News Service

You can subscribe to the Freudenberg Sealing Technologies news alert service, bringing you the news as soon as they are published. You can always unsubscribe from this service.

Subscribe now! chevron_rightFurther Articles With These Taggings

First Hand News

Best of all, keep up with the latest developments

with the Freudenberg Sealing Technologies newsletter.