Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

14.09.2017 | Press release

Freudenberg Sealing Technologies Investigates Conductive Plastics for Radar Sensor Housings

Weinheim (Germany), September 14, 2017 – Radar sensors for assistance systems and highly automated driving must be reliably shielded from environmental influences by robust housings and seals. Until now, they were protected by aluminum carrier housings that Freudenberg Sealing Technologies securely sealed with liquid silicone rubber (LSR) seals. The company is now investigating carrier housings made of plastic that facilitate significantly increased heat conductivity. This not only simplifies the manufacturing process – it allows weight savings of up to 50 percent as well.

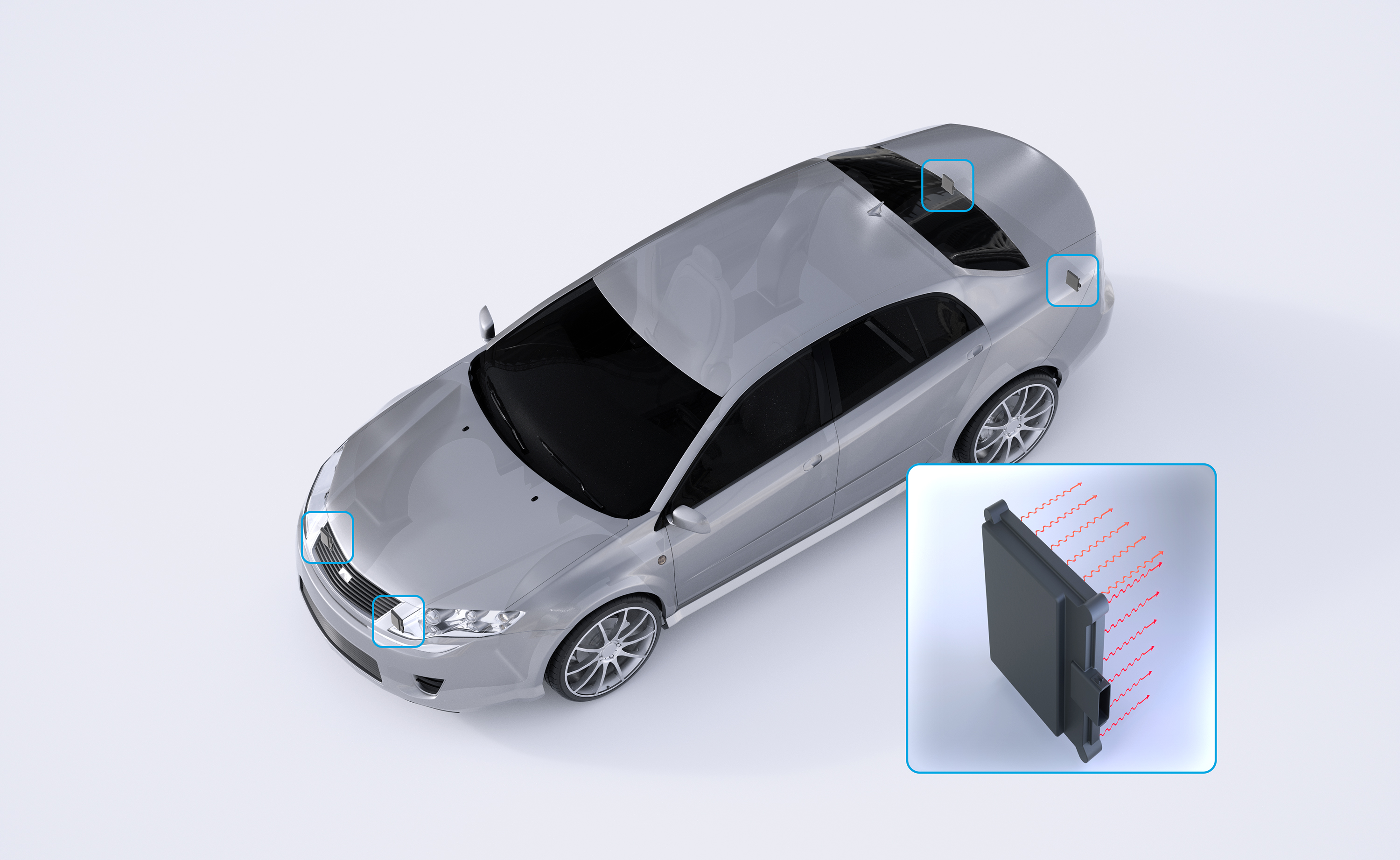

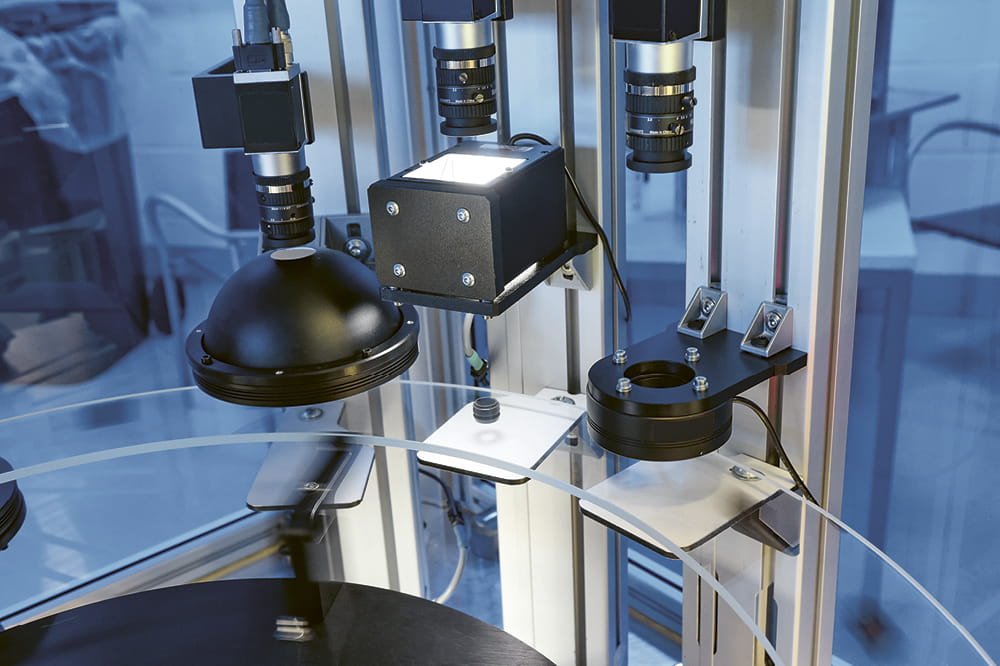

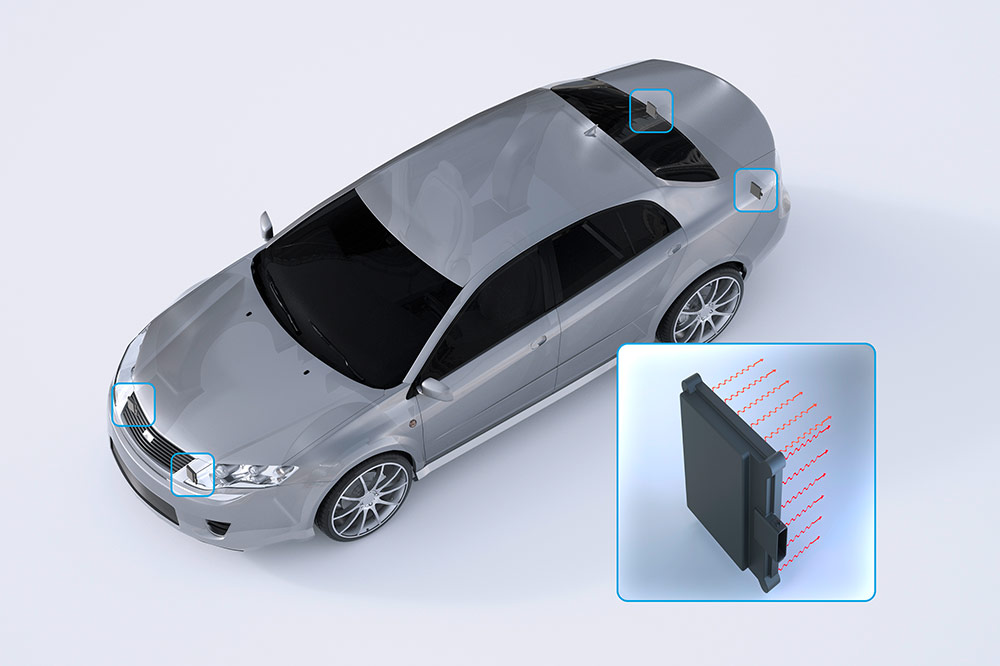

New vehicles are increasingly equipped with driver assistance systems. Automotive engineers are working intensively on automated driving. In these fields, it is crucial for cars to recognize their environment reliably. For example, ultrasound sensors cover the vehicle’s immediate environment over a distance of up to 10 meters. Lidar and long-distance radar sensors reach up to 250 meters. Cameras and radar sensors capture events on the road in the intermediate range. The radar sensors are mostly mounted in pairs behind the front and rear bumpers and are protected from dust, dirt and salt water by a carrier housing made of die-cast aluminum with special silicone seals. A secure, lasting connection of the aluminum housing and liquid silicone seal poses a special challenge: Freudenberg Sealing Technologies handles it by using the appropriate material compound and pretreating its surface. Now the company is doing research on innovative housings that are completely made of plastics. This enables them to be up to 50 percent lighter. The company’s injection molding process also offers advantages for manufacturing, and the adhesion between the housing and the silicone seal can be improved further with a customized recipe for the thermoplastic.

Radar sensors’ circuits are becoming progressively more integrated to allow new smart functions for automated driving. That’s why a growing number of components – for example, for sending and receiving or producing transmission signals – are installed right on the circuit board. The rising power density, however, often leads to greater heat generation. As a result, the issue of thermal conductivity poses a challenge. To begin with, the conductivity of thermoplastics is generally worse than that of metals. The housings must draw off increasing amounts of heat. Engineers at Freudenberg Sealing Technologies face yet another challenge: shielding the electronics components against electromagnetic interference. So far, the amount of metal in housings has provided the protection, and plastics now have to play the same role.

Based on the findings of Freudenberg Sealing Technologies’ material experts, certain base polymers are suited for use as the new plastic compound. They provide the initial mechanical and thermal qualities that are required. Then, with the use of fillers, additives and other measures, they must be manipulated to the point that they achieve the target characteristics, such as mechanical durability, resistance to aging and the necessary adhesive qualities. But heat conductivity is given special attention. With the newly developed compound, it is possible – depending on the design – to boost heat conductivity ten- to one-hundred-fold compared to current thermoplastics. The injection molding process used to produce the carrier housings then makes a special design possible. Through the use of dissipating elements, engineers can achieve overall thermal management and ensure electromagnetic compatibility thanks to a new structure.

Compared to aluminum die casting, the injection molding process used for thermoplastics not only offers greater freedom of design with significantly lighter components. It also makes it possible to cut a complete step from the production process because the pretreatment of the aluminum blank's surface is eliminated. This simplifies manufacturing and reduces the number of potential sources of error in the production process. Another example: The material experts at Freudenberg Sealing Technologies can individually configure the adhesive qualities of the plastic housing and the silicone seal. That means the seal can fulfill its function reliably and durably even under high loads.

It is a special advantage to be able to consider the use of plastics for housings early in the development of future sensor concepts. Then the Freudenberg Sealing Technologies engineers can adjust the properties exactly to the specific application and shape the design to meet its requirements. That’s because the great advantage of thermoplastics is that their characteristics can be “bred” for particular requirements on a targeted basis. In this way, in a spirit of cooperation and partnership, sensor systems that are lightweight, high-performing and optimized for their installation space can be developed for automated driving.

Ulrike Reich

Head of Media Relations & Internal Communications

Telephone: + 49 (0) 6201 960 5713

ulrike.reich@fst.com chevron_rightNews Service

You can subscribe to the Freudenberg Sealing Technologies news alert service, bringing you the news as soon as they are published. You can always unsubscribe from this service.

Subscribe now! chevron_rightMore news on the subject Technology & Innovation

First Hand News

Best of all, keep up with the latest developments

with the Freudenberg Sealing Technologies newsletter.