Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

07.05.2018

Reliable, Affordable Sealing Solutions for the Steel Industry

Freudenberg has extensive experience with energy saving seals that lower overall system friction. But unlike in the automotive industry, where energy saving seals are frequently used to address emission challenges, energy saving seals used in the steel / metallurgical industry must conserve energy in heavy, power-intensive operations while also insuring that the equipment continuously runs. Equipment failure in a steel mill is cost and time prohibitive.

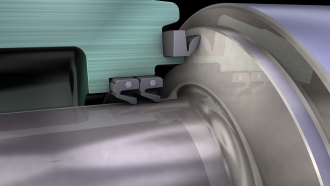

One high performance solution, and a highlight of Freudenberg’s AISTech exhibit, is the Merkel® Radiamatic RPM 41 radial shaft seal. The RPM 41 helps protect costly work roll bearings by keeping lubricant in and keeping water out. This seal, currently in use at 35 steel mills across North America and Europe, offers customers reliability at an affordable price.

“The RPM 41 offers numerous advantages for our steel industry customers, from affordability, to ease of installation, to durable service life,” said Robin Moeller, Business Development Manager at Freudenberg Sealing Technologies. “We know that the operating conditions in this industry are extreme and that any equipment failure can lead to costly downtime. Our sealing solutions are readily available off the shelf or can be custom designed and provide optimal, reliable performance.”

The RPM 41 seal comes with a Merkel® Enviromatic water guard, which features a defined linear contact of the sealing edge that can protect against water and dirt ingress even in cases of axial shaft misalignment. The seals are offered along with Freudenberg’s complete service package, which includes first time installation assistance on-site, troubleshooting support and replacement seals that are shipped to the customer within 24 hours.

In addition to the RPM 41 seal and Enviromatic guard, Freudenberg will showcase a variety of other steel industry focused sealing products at its AISTech booth #1525, including state-of-the-art polytetrafluoroethylene (PTFE) seals and guide bands for the demanding cycles of hydraulic automatic gauge control (HAGC) cylinders, as well as a complete range of off the shelf industry standard seals to serve cost sensitive applications.

Featuring technologies from all over the world that help steel producers to compete more effectively in today’s global market, AISTech is an event for anyone involved at any level of today’s steel marketplace, providing perspective on the technology and engineering expertise necessary to power a sustainable steel industry.

More information on Freudenberg Sealing Technologies products and solutions for the steel industry is available here.

Download Documents

Download Images

News Service

You can subscribe to the Freudenberg Sealing Technologies news alert service, bringing you the news as soon as they are published. You can always unsubscribe from this service.

Subscribe now! chevron_rightFurther Articles With These Taggings

First Hand News

Best of all, keep up with the latest developments

with the Freudenberg Sealing Technologies newsletter.