Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

17.01.2018 | Press release

Freudenberg Sealing Technologies Helping Customers Find Material Solutions in the Ever-Changing Mobility Landscape

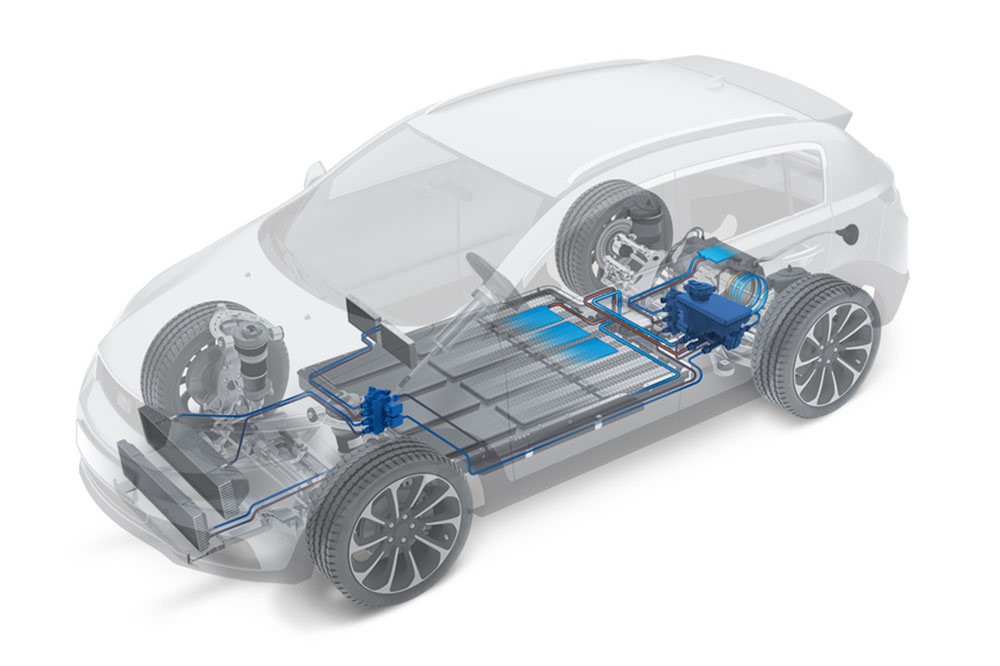

Detroit (USA), Jan. 17, 2018. From turbocharged engines and 10-speed transmissions to electrified and electric vehicle systems, the propulsion technologies on display at the 2018 North America International Auto Show (NAIAS) offer evidence that significant industry changes are afoot. Regardless of the fuel used – gasoline, methanol, ethanol, biodiesel fuel oil blends, electricity or compressed natural gas – the newest powertrain assemblies being unveiled in Detroit this week have been engineered to meet some exacting power, efficiency, safety and environmental standards. Key to their success are components manufactured from innovative materials like those developed by Freudenberg Sealing Technologies.

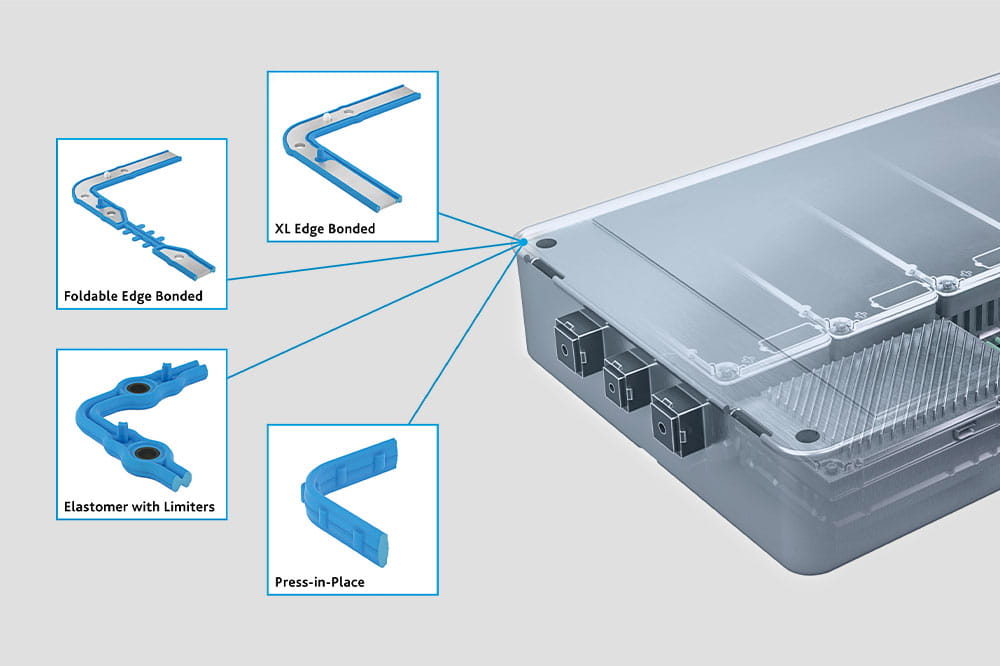

Freudenberg Sealing Technologies, a global sealing specialist to diverse industries, has spent decades researching new materials formulated to handle industrial challenges associated with temperature, pressure, fluid compatibility and contaminants. In the automotive industry, where new powertrain technologies operate in smaller, hotter, more thermally-dynamic environments, Freudenberg’s proprietary elastomers and high performance plastics reduce friction, lower weight, increase chemical resistance and promote operational longevity in both static and dynamic component applications.

“We are looking at new, innovative sealing materials for batteries, fuel cells and other novel propulsion systems while also optimizing our portfolio for conventional engines as well,” said F. Joseph Walker, Global Technology Director, Materials and Laboratory Services, Freudenberg-NOK Sealing Technologies. “Advances in vehicle technology have made material compatibility absolutely key today. Freudenberg-NOK runs the business operations for Freudenberg Sealing Technologies in the Americas.

“Today’s powertrain systems are more complex than ever before, and they are still under development so requirements continue to change,” Walker continued. “Material compatibility challenges are really about risk management – component manufacturers incur risk every time their materials are subjected to new fluids and environments. Our goal is to supply customers with a material that works regardless of design and application challenges.”

Thermal management and friction reduction, for example, have emerged as even greater needs in today’s new vehicles. Powertrain components in electric and electrified vehicle must exhibit high thermal conductivity but low electrical conductivity – large, high-voltage batteries need to be cooled but their electricity must not escape. Friction reduction, which helps increase efficiency and lower emissions, becomes even more important with sealed, lifetime fluid systems where shafts are running on an ever-thinning thickness of lubricant at faster speeds. Autonomous driving scenarios, where ride comfort and operational longevity are essential, will increasingly depend upon friction reduction in shock absorbers and suspensions.

“The enemy is heat,” Walker said. “Today, we are packing so much into power transfer cases that you may end up with only a cup of lubricant. We need to know how materials will respond to new temperature and pressure extremes.”

Freudenberg is at the forefront of helping auto manufacturers navigate an evolving material landscape. The company offers customers more than 1,800 material formulas globally. Among its many high-performance, proprietary materials, five, in particular, offer unique advantages to customers: Quantum® PTFE, Quantix® Thermoplastics, High Temperature FKM, FluoroXprene® and Bio-based EPDM.

Here you find more information on the material solutions that Freudenberg Sealing Technologies offers.

Visitors to NAIAS are invited to view all of Freudenberg’s innovative sealing solutions Jan. 16-18, 2018 at its display at the Crowne Plaza Hotel Detroit Riverfront in the Pontchartrain Room.

Press Release Downloads

Freudenberg Sealing Technologies Helping Customers Find Material Solutions in the Ever-Changing Mobility Landscape

Last update: 17.01.2018

English | DOCX | 89 KB

DownloadNews Service

You can subscribe to the Freudenberg Sealing Technologies news alert service, bringing you the news as soon as they are published. You can always unsubscribe from this service.

Subscribe now! chevron_rightMore news on the subject Automotive & Transportation

First Hand News

Best of all, keep up with the latest developments

with the Freudenberg Sealing Technologies newsletter.