Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

17.10.2019

XALT Energy Introduces Low Profile Lithium-Ion Battery Pack for Commercial Vehicles

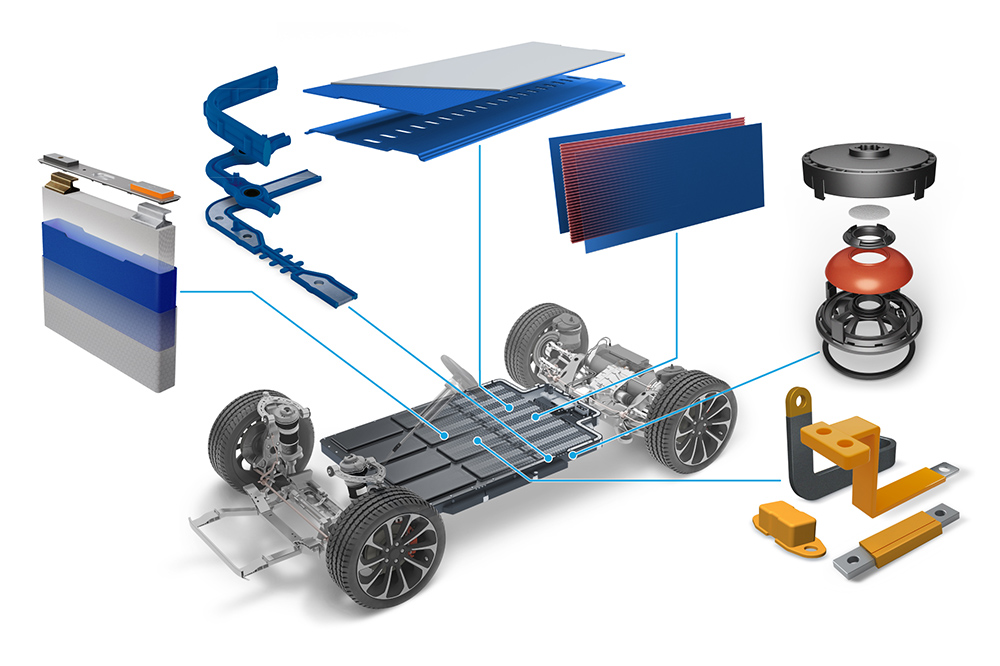

The XPAND Low Profile (XLP) Pack can be installed in buses, trucks and trains in spaces where height or depth is limited. At 185 mm high, 612 mm wide and available lengths of between 360-1080 mm depending on the energy capacity, the XLP Pack is designed to fit securely within the frame rails of new and existing medium and heavy trucks and buses. The design eliminates the need for OEM manufacturers to redesign and raise the floor of delivery trucks and buses in order to accommodate the high amount of energy storage required for long-range applications. The XLP Pack can be mounted horizontally or vertically, providing even greater packaging flexibility. This low-profile option, coupled with XALT’s proven battery management system architecture, offers flexible, fast-charging, clean power options for vehicles used extensively in large urban areas.

Vehicle-Friendly Pack Design for Tight Spaces

“The XLP Pack allows customers to take advantage of XALT’s most advanced lithium-ion battery innovations without requiring significant vehicle design modifications,” said Martin Klein, Senior Vice President, Engineering, XALT Energy. “As regulators continue to toughen air quality and emission standards in cities, fleet owners will increasingly rely on battery electric buses and trucks to meet urban transportation needs. The XLP Pack will facilitate easier implementation of XALT’s lithium-ion battery solutions.”

Similar to other products in XALT’s XPAND portfolio, the XLP Pack is direct liquid cooled, can be connected in series up to 1250V per string and has an IP67 rated enclosure. The pack design accommodates side or bottom mounted interface brackets. Standard configurations for the XLP Pack will include one, two or three cell subpacks within a single enclosure with further packaging customization available.

Sustainable Technology for Heavy Duty Applications

“XALT’s family of energy and power cells are an industry benchmark and have long been recognized for their superior cycle life and performance in the toughest conditions,” said Lisa McKenzie, Senior Vice President, Cell Research and Development, XALT Energy. “Our ability to leverage multiple electro chemistries and process excellence across two cell formats gives our customers unparalleled flexibility across their product lines in fast-charge, high-power applications and long-range, high-energy applications.”

XALT and Freudenberg Sealing Technologies are jointly focused on the development and support of new electric powertrain solutions for heavy duty and commercial applications in urban environments. While a recent World Resource Institute report indicates that the number of electric buses in use in global cities has increased 80-fold between 2011 and 2017, concerns about the reliability, range, charging times and cost of such systems remain. XALT’s XPAND family of heavy-duty lithium-ion battery systems are designed to resolve these concerns.

Vertically Integrated Manufacturing for Top Quality

As a fully-integrated, fully-automated, lithium-ion battery manufacturer, XALT handles every aspect of system production from cell research, design and manufacturing to pack design and final assembly. The company’s 460,000-square-foot manufacturing plant in Midland is the largest industrial facility in Freudenberg’s global portfolio. Since its construction eight years ago, the plant has implemented premium quality control programs, efficient production processes that are supported by high-end robotic stacking and vision systems and class 10,000 and class 1,000 clean rooms. The company’s vertical integration facilitates complete material tracking, testing and traceability. Freudenberg will continue to invest in system and equipment upgrades at the world-class facility going forward, said Jeff Michalski, CEO, XALT Energy.

“XALT has tripled its production of lithium ion battery systems during 2019 as it ramps up operations to handle increasing industry demand for sustainable powertrain options in the commercial vehicle sector,” Michalski said. “We continue to invest in the plant, its technology, and additional employees to ensure we can fully meet the expectations of our current and future battery customers. This is an exciting time for XALT as the application of the company’s NMC/Graphite battery systems continues to grow across a variety of sectors.” XALT Energy will launch production of the XLP Pack with existing cell technology in its Midland operations in 2021.

Freudenberg Sealing Technologies and XALT Energy will showcase a variety of medium- and heavy-duty lithium-ion battery and fuel cell technologies at Busworld 2019 in Brussels, Oct. 18-23. In addition to the new XLP Packs, XALT will display its proprietary 43Ah SHP cell technology, its XPAND Energy Storage System and telematics at booth #310b. Freudenberg will highlight the latest innovations in fuel cell technology. For more information about Busworld, go to www.busworldeurope.org

Download Documents

Download Images

News Service

You can subscribe to the Freudenberg Sealing Technologies news alert service, bringing you the news as soon as they are published. You can always unsubscribe from this service.

Subscribe now! chevron_rightFurther Articles With These Taggings

First Hand News

Best of all, keep up with the latest developments

with the Freudenberg Sealing Technologies newsletter.