Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

19.09.2019

Minimal Resistance

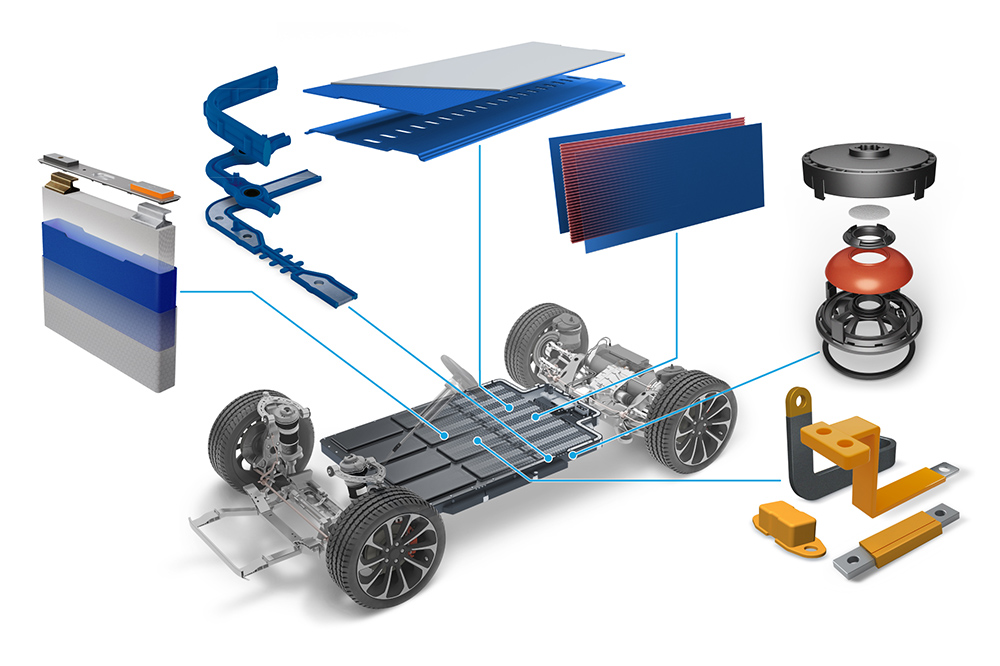

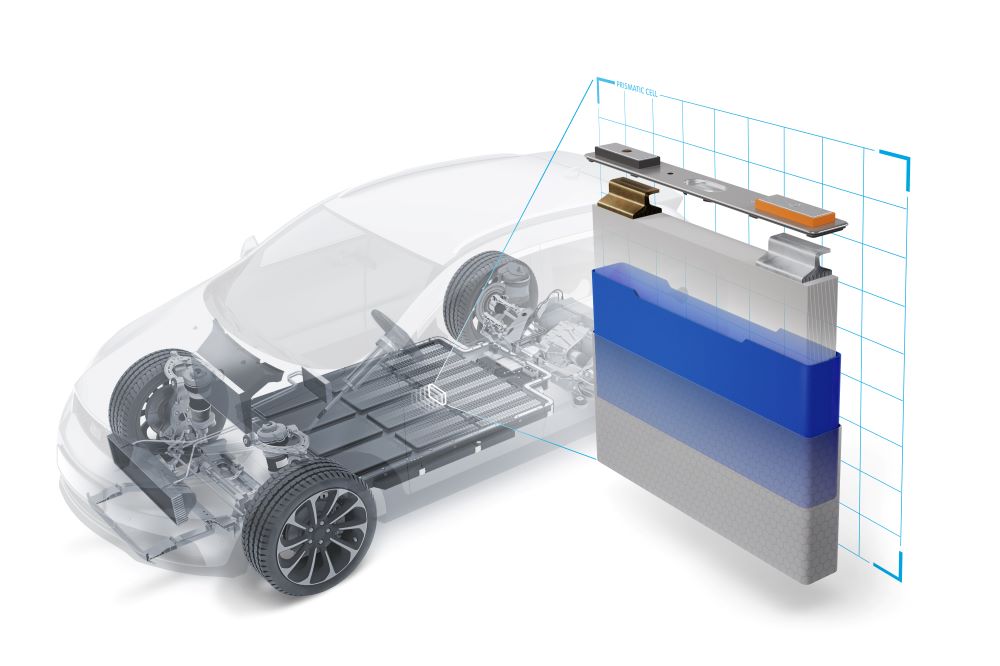

In many operating conditions, the shafts used in electric powertrains are electrically insulated from their housings. The insulation is created by the lubricating films in the contact zones for the bearing and the shaft seals. Lubrication is necessary to promote long-term system functionality. Alternating current and its electromagnetic fields produce changes in the electric potential between the rotor and the stator and the rotor becomes charged. The current can only be drained off through a grounded system that allows the electricity to travel from the shaft to the housing. If there is no grounded pathway, the current flows to the area of least resistance – the bearing – and produces an abrupt discharge when electricity flows from the inner ring to the outer ring across the bearing. Discharge flashes cause surface burns and material compromises that permanently damage the system. The result: The contact surfaces in the rolling bearing are steadily and systematically destroyed. The mounting becomes noisy and the bearing must be replaced to prevent powertrain failure.

Finding the conducting element

Damage from electric current must absolutely be avoided. The simple solution is to develop a lasting, reliable electrical contact between the shaft and the housing that facilitates a continuous flow of electricity and prevents excessive build up and sudden discharges. The more difficult challenge is to find a system element that can conduct the current via ongoing contact with both the housing and the shaft. As a rule, seals are made of insulating materials and are not suited for this purpose.

For several years, Freudenberg Sealing Technologies has been producing an electrically-conductive nonwoven disk as a series- production system element. The advantage: It is firmly connected to the shaft seal ring and requires almost no additional installation space. The conductivity of the nonwoven is achieved with special fibers that are embedded in a matrix. The system has been used in regular-production electric vehicles for years and reliably prevents bearing damage. The electric resistance in this approach is already at a very low level, but the sealing specialists at Freudenberg Sealing Technologies continue to develop the solution further.

Power densities continue to grow in upcoming electric powertrains, increasing current, voltage and disruptive electromagnetic fields. To offer a robust solution for these situations, the company is now developing a new generation of conductive seals. The first validated, functional models in this category will be available within a few months. “Our goal is to achieve constant resistance values over a long period of operation – even in adverse conditions,” said Dr. Tim Leichner, who is responsible for Strategic Product Advance Development at Freudenberg Sealing Technologies.

A new dynamic testing procedure

To fulfill the new requirements for seals in electric powertrains, Freudenberg Sealing Technologies has developed the appropriate test procedure to evaluate and compare the functioning of current dissipation elements. Test stand trials have shown that static measurements of the elements’ electrical resistance are not adequate to predict electrical conductivity during actual dynamic use. So development engineers in Germany developed a dynamic testing procedure that delivers alternating-current flows in the frequencies found in automobiles.

“There is the possibility of doing even more with conductive seals,” said Francois Colineau, who is in charge of the development of this product line at Freudenberg Sealing Technologies. “High electrical conductivity lends itself to possible shielding of disruptive electromagnetic radiation.” The exit point of the shaft from the housing, in particular, is normally a location where “impermeability” is only achieved with difficulty. At this location on every electric motor, there is a shaft seal that could help handle the shielding. It would be possible to combine the sealing of oil and other media with impermeability to electromagnetic radiation – without necessarily adding another nonwoven layer. “Perhaps we will even find an entirely new electrically conductive sealing material. We’re working on it,” Colineau said.

Ulrike Reich

Head of Media Relations & Internal Communications

Telephone: + 49 (0) 6201 960 5713

ulrike.reich@fst.com chevron_rightDownload Documents

Download Images

News Service

You can subscribe to the Freudenberg Sealing Technologies news alert service, bringing you the news as soon as they are published. You can always unsubscribe from this service.

Subscribe now! chevron_rightFurther Articles With These Taggings

First Hand News

Best of all, keep up with the latest developments

with the Freudenberg Sealing Technologies newsletter.