Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

08.09.2020

Fuel Cells for Heavy-Duty Trucks

The 40-ton heavy-duty trucks are the titans of the highways. Thanks to their large loading volume, they enjoy great popularity among freight carriers. While state-of-the-art technologies have been implemented in this weight class in recent years to improve environmental performance, safety and efficiency, overall fuel consumption and vehicle emissions still remain a challenge. This is true particularly within the European Union, where trucks account for 25 percent of the entire CO2 emissions in the transportation sector.

While battery-electric vehicles can be used efficiently and in an eco-friendly way in urban areas, fuel cell technology offers the optimal approach when it comes to emission-free logistics over long distances and with higher payloads. Electric commercial vehicles that are powered solely by batteries are not suited for everyday operations, partly because of longer charging cycles and limited range. During stop-and-go traffic or traffic jams, the battery loses significant power. An additional, time-consuming refueling stop is economically inefficient. A battery-powered electric drive may also require concessions in terms of payload.

An alternative to the 40-ton truck with diesel drive

Freudenberg Sealing Technologies’ fuel cell expertise is focused on making emission-free, economically viable heavy-duty transportation a reality. In the past year, the company has launched successful development projects for buses and cruise ships with partners such as FlixBus and Meyer Werft in Germany. With the cooperation of Quantron AG, a specialist in retrofitting existing commercial vehicles with electric powertrains and batteries, Freudenberg has now turned its attention to truck solutions in the 40-ton weight class to create a low-emission alternative to standard commercial heavy-duty trucks powered by diesel drivetrains. The goal is to test the fuel cell systems for performance, durability and range under continuous commercial driving conditions. The project is funded by the Energy Research Program of the Bavarian State Ministry of Economic Affairs, Regional Development and Energy and is one of the first initiatives that explicitly supports the development of a fuel cell for use in heavy-duty trucks. A first test vehicle with the new drive technology is expected to be rolling across Bavarian roads in mid-2021. The vehicle named Energon was presented to the public in early August this year.

“Fuel cell trucks are the only economical, emission-free alternative that permits large payloads as well as significant ranges and fast refueling cycles,” said Dr. Manfred Stefener, Vice President Fuel Cell Systems at Freudenberg Sealing Technologies. “That's why we are looking forward to working with Quantron AG to create fuel cell applications that are explicitly designed for the maximum load and operating points of trucks.”

Clear focus on heavy-duty trucks

Fuel cells for trucks must cover completely different load and operating profiles than those for passenger cars: On average, a passenger car drives for a maximum of one hour per day and stands still for the remaining 23 hours. This is why passenger car systems are designed for only 5,000 to 8,000 operating hours. Truck systems, in contrast, require a service life of at least 35,000 hours. This is because commercial vehicles earn money exclusively through reliable, continuous operation.

As it focuses on heavy-duty trucks, the current project offers additional innovations. These include, for example, the consistent use of material combinations that optimize the service life as well as the development of special interfaces for space-optimized application in a commercial vehicle. This makes it possible to perform maintenance, repair and replacement tasks with a minimal effort at any time and, thanks to the standardization, to operate a maximum range of vehicles. Existing fuel cell systems were originally developed for passenger cars. For heavy-duty applications, however, all essential design aspects of the system have to be optimized for a long service life.

“The goal is to develop fuel cells that can manage a long service life and real heavy-duty profiles to outshine the diesel when it comes to total cost of ownership,” Dr. Stefener said. “We intend to launch a sustainable, emission-free alternative for heavy-duty traffic on the market.”

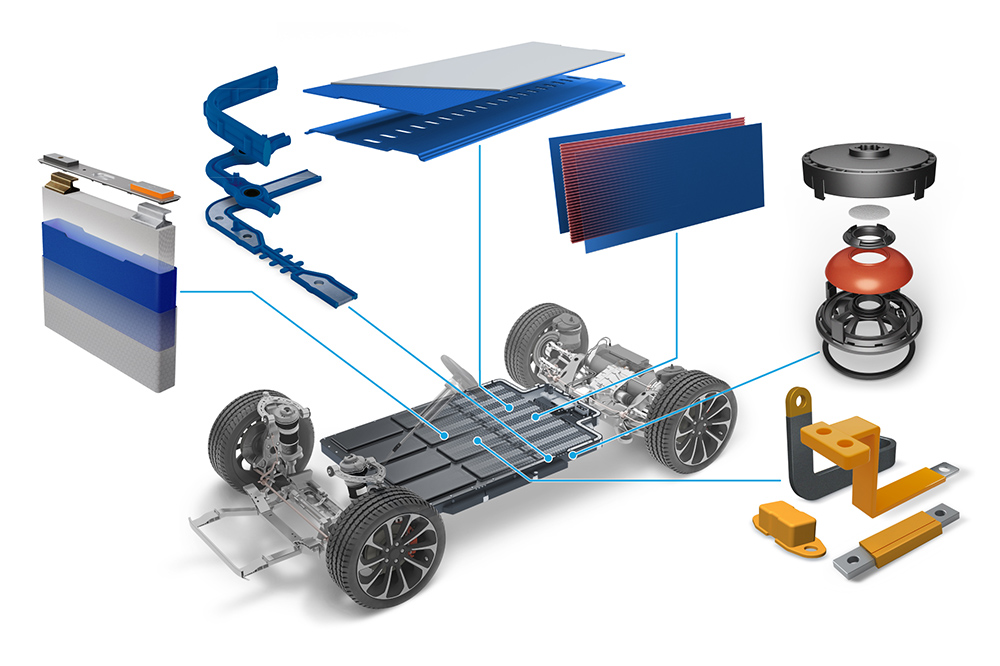

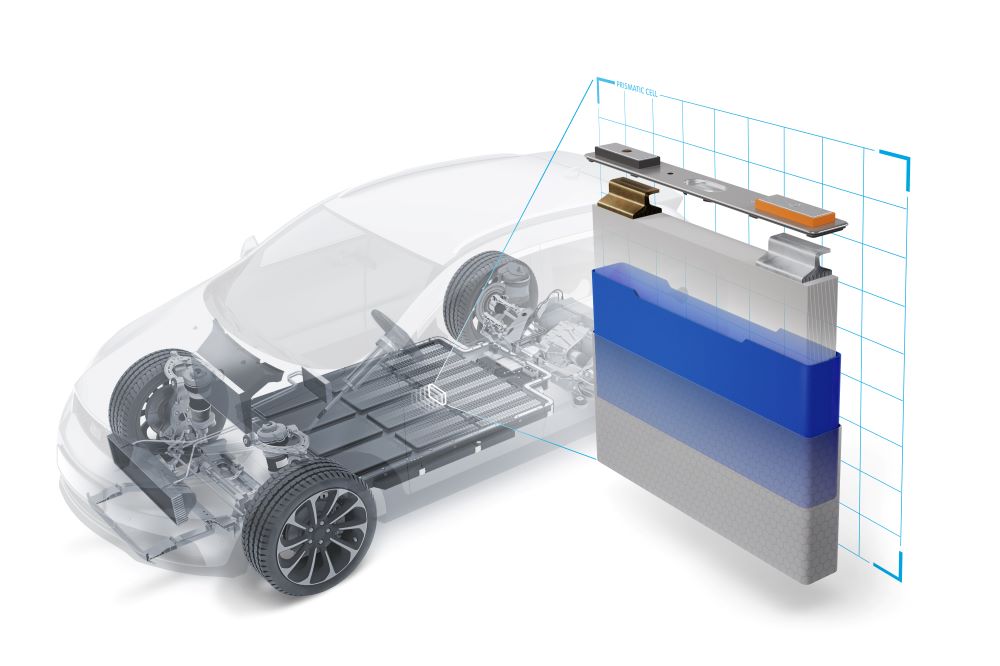

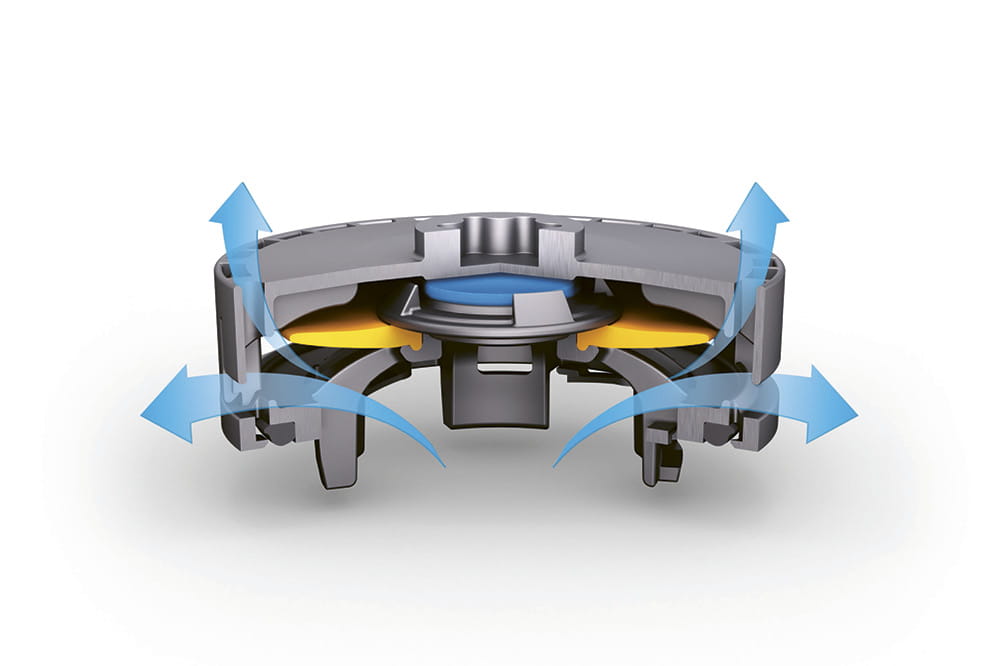

For decades, Freudenberg Sealing Technologies has been supporting automotive and commercial vehicle manufacturers in reducing the fuel consumption and emissions of their internal combustion engines with innovative sealing technology. In the mid-1990s, the Freudenberg Group, began conducting research into alternative drive concepts and started developing technically-sophisticated components for fuel cells and batteries. Among other things, the company has developed gas diffusion layers (GDL), humidifiers, filter solutions and seals for fuel cell stacks that are ready for series production.

Unique depth of value creation at the company

At the beginning of 2018, Freudenberg Sealing Technologies strategically supplemented this expertise by acquiring fuel cell manufacturer, Elcore. As a result, the company now offers comprehensive systems competence as well as deep value creation in the core components of fuel cells. In 2019, Freudenberg Sealing Technologies also acquired majority ownership of US-based XALT Energy, a market leader in the development and production of advanced lithium-ion batteries and battery solutions.

These strategic acquisitions have positioned Freudenberg Sealing Technologies as a market leader in the development and production of alternative and electric drivetrain solutions focused on both lithium-ion batteries and fuel cells. This provides a significant value benefit for customers. The company is actively capitalizing on this depth of expertise: The in-house production of gas diffusion layers, permeable sealing materials and catalysts forms the basis for fully integrated membrane-electrode assembly (MEA) and offers the starting point for truck fuel cells of the future.

“Merely assembling purchased components is not a solution for the heavy-duty fuel cells of the future in high volumes,” said Claus Möhlenkamp, CEO of Freudenberg Sealing Technologies. Instead, the company focuses on the design of the overall system and the targeted further development of its material and design expertise at a component and system level. “With this research and development project, we are consistently pursuing our fuel cell strategy for heavy-duty applications,” Möhlenkamp added. “Thanks to our cooperation with Quantron AG, we can bring the latest research results of the Freudenberg Group for truck fuel cells on the road within a very short time.”

Ulrike Reich

Head of Media Relations & Internal Communications

Telephone: + 49 (0) 6201 960 5713

ulrike.reich@fst.com chevron_rightDownload Documents

News Service

You can subscribe to the Freudenberg Sealing Technologies news alert service, bringing you the news as soon as they are published. You can always unsubscribe from this service.

Subscribe now! chevron_rightFurther Articles With These Taggings

First Hand News

Best of all, keep up with the latest developments

with the Freudenberg Sealing Technologies newsletter.