Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

25.01.2023 | Press release

Certified Safety for the Food Industry

Weinheim (Germany), January 25, 2023. The technical components used in the packaging industry are subject to strict standards that include country and industry-specific hygiene requirements such as the EHEDG (European Hygienic Engineering and Design Group) guidelines. The tubular heat exchanger from Tetra Pak that features a specially developed seal from Freudenberg Sealing Technologies was the first and only device on the market to receive EHEDG approval.

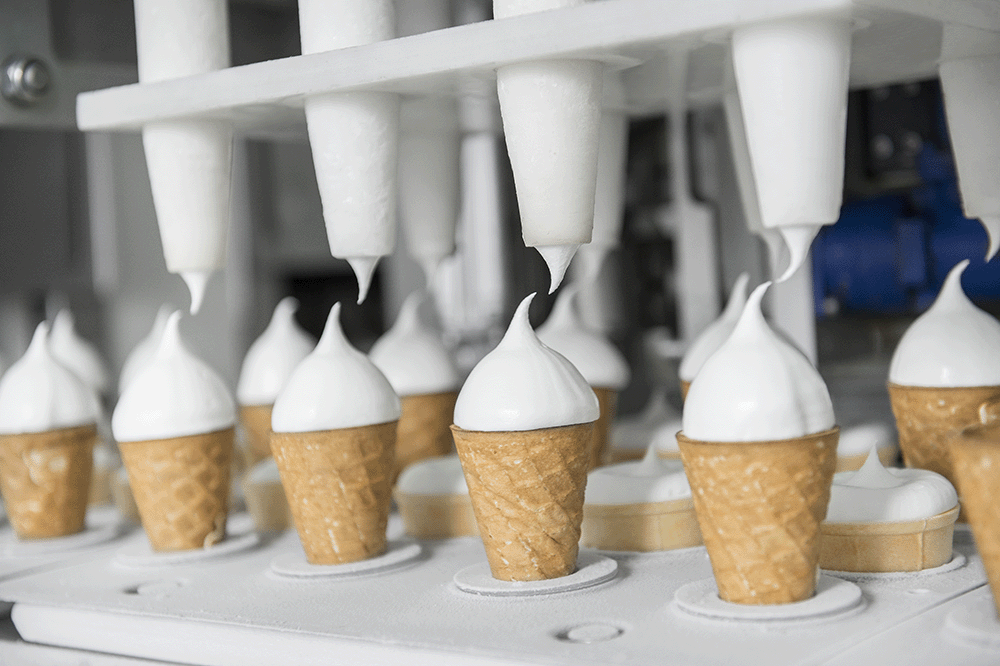

The objective of the development cooperation between Freudenberg and Tetra Pak was to develop a cost-effective, hygienic sealing solution that would connect the stainless steel components of the new tubular heat exchanger. Tubular heat exchangers are used in food industry process lines wherever liquid products with different viscosities and solid contents are to be heated to achieve a longer shelf life. To prevent product contamination, all components of the new tubular heat exchanger that come into contact with the product must meet demanding industry-specific requirements. Besides Hygienic Design Standards, these include statutory regulations such as FDA, EG (Reg.) 1935/2004 and 3-A® Sanitary Standards.

Before the new sealing solution for this special application was ready for series production, Freudenberg Sealing Technologies and Tetra Pak also had to overcome other challenges: The sealing material not only had to be resistant to CIP/SIP media (Cleaning in Place / Sterilization in Place), but also had to accommodate a broad temperature range with particularly high temperatures and at the same time be designed for a long service life.

From modeling to prototyping to production readiness

In search of an appropriate, cost-effective sealing solution, Tetra Pak turned to Freudenberg, who was able to convince them thanks to its extensive research, development and production capacities. In addition, Tetra Pak had already gained positive experience working with Freudenberg in many development partnerships in the area of homogenizers. Once all the requirements for the sealing solution had been defined, the Freudenberg Sealing Technologies team began with development work in close cooperation with Tetra Pak’s technical team.

Thanks to own FEM models, it was possible to determine the service life of the new seal in advance and optimize the design of the seal. CNC machining of prototypes with the Freudenberg Xpress® service eliminated the need for tool production to save time and costs. Challenges such as high temperatures, which proved to be very complex in the FEM analysis, were mastered by the teams working closely together.

High-performance materials for food-compliant applications

Choosing the right sealing materials was a key factor in this regard. The two materials used, 70 EPDM 291 and 75 Fluoroprene® XP 40, meet the requirements of the FDA, EG (Reg.) 1935/2004, NSF 51 and the 3-A® Sanitary Standards. In addition, they are optimized especially for cleaning in CIP/SIP processes. Both materials cover a wide range of temperatures: 70 EPDM 291 between -40 °C and +150 °C, 75 Fluoroprene® XP 40 between -15 °C and +200 °C.

The developers further optimized the design and performance of the new product until all requirements could be met. As a result, the tube modules comply with the latest EHEDG guidelines and is currently the only solution on the market to have received the respective approval. Tetra Pak is now having the newly developed sealing system produced in series, with four more dimensions planned.

“We are proud to be able to help make food production safer with our sealing solution that is based on our extensive development and materials expertise,” explains Mats Harrysson, Key Account Manager Global Process Industry at Freudenberg Sealing Technologies.

Ulrike Reich

Head of Media Relations & Internal Communications

Telephone: + 49 (0) 6201 960 5713

ulrike.reich@fst.com chevron_rightNews Service

You can subscribe to the Freudenberg Sealing Technologies news alert service, bringing you the news as soon as they are published. You can always unsubscribe from this service.

Subscribe now! chevron_rightMore news on the subject Industrial Applications

News Service

You can subscribe to the Freudenberg Sealing Technologies news alert service, bringing you the news as soon as they are published. You can always unsubscribe from this service.

Subscribe now!