Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

12.09.2023 | Press release

Innovation for Electric Vehicles: The Tightest of Seals

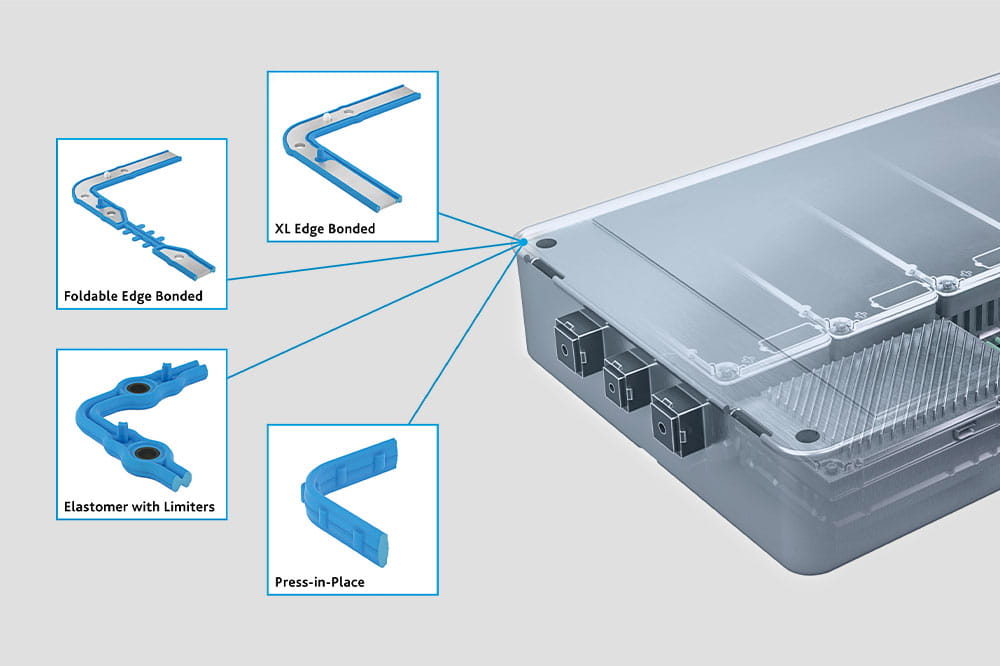

Weinheim (Germany), September 12, 2023. Freudenberg Sealing Technologies, the world's leading provider of sealing solutions, is launching a crucial product innovation for the automotive industry: an impermeable rectangular busbar overmold that seals reliably and helps prevent damage to an electric vehicle’s power electronics. The solution also reduces assembly complexity by combining the busbars, seal and guide in one complete package that is ready for installation on the vehicle assembly line. The new product will be showcased for the first time at the upcoming Battery Show in Detroit.

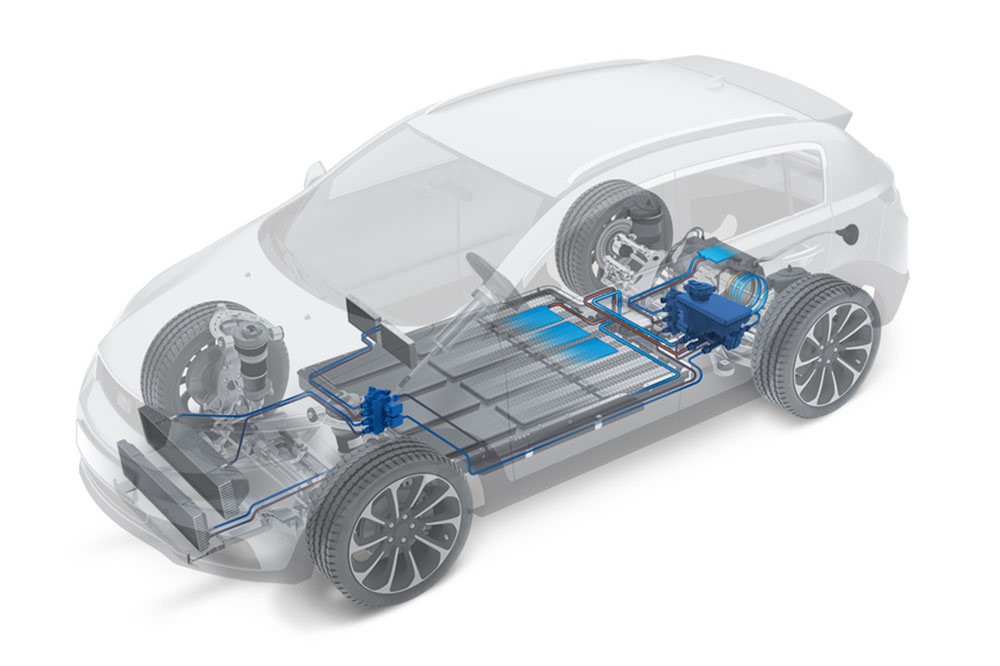

Oil-cooled electric motors are commonly employed in various electric vehicles. To maintain reliable vehicle operations, it is crucial to protect sensitive power electronics within the inverter from exposure to motor oil by sealing around the busbar motor / inverter interface. Additionally, other electrical busbars with rectangular geometries, like those found in immersion cooled batteries and oil pumps, also require sealing along their metallic cables. This necessity underscores the importance of establishing a permanent seal for the current-carrying rectangular conductors, often referred to as 'busbars'.

However, achieving tight seals with busbars having rectangular geometries poses challenges. Traditional busbars are die-cut from copper or aluminum sheets and then bent to the desired shape. The resulting rectangular busbar is not ideal for standard sealing, as the corners prevent effective compression of the sealing material. Even attempts to enhance the contact surface with partially embossed edges or press-on structures do not yield satisfactory sealing results. Post-processing methods like potting can be used but are time-consuming and impractical for large-scale industrial applications. They also require additional space, limiting busbar design flexibility.

State-of-the-art: rectangular sealing

Freudenberg Sealing Technologies has now succeeded in developing a sealing innovation that reliably seals rectangular busbars and can prevent associated damage to the power electronics in electric vehicles. This recently patented, sealed, rectangular busbar overmold includes an elastomeric layer, which is applied to the rectangular busbar and bonds firmly with the metallic conductor and the surrounding plastic later in the manufacturing process. This innovation will be on display at Freudenberg Sealing Technologies' booth (2411) at the Battery Show in Detroit from September 12 to 14 (Suburban Collection Showplace, Novi, Mich.)

"Sealing rectangular shapes is considered the pinnacle in sealing technology, as leakage points often occur in the corners. Thanks to an elastomer layer between the metal and plastic we can now produce sealed busbars - and in a way that saves valuable space, as component and seal virtually become one. This new solution from Freudenberg Sealing Technologies enables our customers to seal their busbars even more reliably, while at the same time offering a high degree of design latitude," says Parisa Burger, Business Development Manager and Project Manager at the company.

Technical innovation offering numerous benefits

The new busbar seal configuration enables an impermeable bond to be created by chemically pretreating the conductor surface with a primer and applying a special elastomeric coating. This creates a firmly bonded intermediate layer, which is followed by thermoplastic injection molding. The elastic material should preferably be based on vulcanizable elastomers such as FKM, AEM, ACM, HNBR, NBR, EPDM, but thermoplastic elastomers (TPE) can also be used.

At the same time, the flexible coating reduces stress on the threshold between the copper and the thermoplastic matrix. The elastic coating reduces the notch effect at the conductor edges, which minimizes the susceptibility of the electronic component to stress cracking.

"We are proud to offer our customers a solution that is not only technically advanced, but also saves time and space, and is cost efficient. This solution provides a wide range of benefits and application options. In particular, the inverter’s sensitive power electronics can now be reliably protected from liquids originating from the electric motor," said Burger.

Freudenberg Sealing Technologies at the Battery Show 2023

The Company is regularly represented by its sales and technical experts at all major trade shows. The next event: the Battery Show 2023 in Detroit from September 12 to 14, 2023 (Suburban Collection Showplace, Novi, MI, Booth 2411).

Ulrike Reich

Head of Media Relations & Internal Communications

Telephone: + 49 (0) 6201 960 5713

ulrike.reich@fst.com chevron_rightNews Service

You can subscribe to the Freudenberg Sealing Technologies news alert service, bringing you the news as soon as they are published. You can always unsubscribe from this service.

Subscribe now! chevron_rightMore news on the subject Automotive & Transportation

News Service

You can subscribe to the Freudenberg Sealing Technologies news alert service, bringing you the news as soon as they are published. You can always unsubscribe from this service.

Subscribe now!