Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

06.12.2023 | Press release

Long Live The Battery!

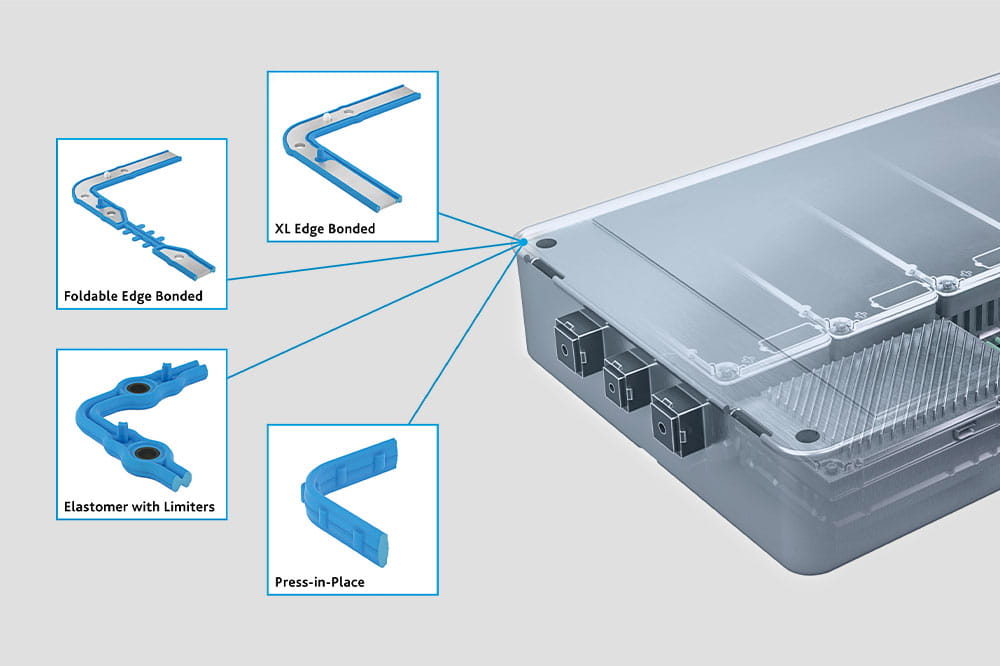

Weinheim/Langres, December 6, 2023. There is good reason to celebrate: Freudenberg Sealing Technologies is offering a new type of foldable gasket for battery electric vehicles – and now the number of these units produced in Langres, France, has reached one million. With this gasket design, Freudenberg significantly contributes to the reliability and longevity of battery systems – while also promoting the sustainable mobility of tomorrow. Automobile manufacturers worldwide rely on the innovative solutions from Freudenberg.

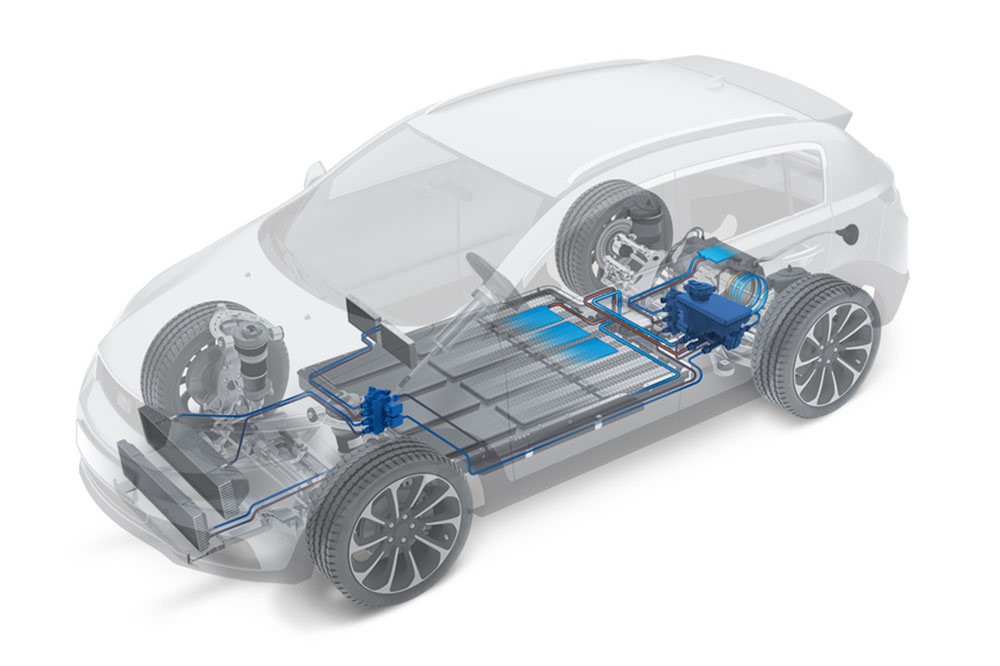

The number of electric cars on the roads is growing constantly – by 2030, more than 100 million electrically powered vehicles are expected to be running worldwide. To make sure that the drivers can enjoy their electric vehicles for as long as possible requires a well-protected battery system. In normal operation, for example, splash water must be prevented from entering through the gap between the battery cover and housing. This task is handled by the battery housing gasket that can be up to eight meters long, depending on the size of the enclosure. But the seal must do far more than just protect against contamination. If there is a thermal event in the battery, it should help contain the flames too.

Freudenberg Sealing Technologies has developed various sealing solutions for battery systems. In Langres, France, the number of innovative foldable gaskets produced has just passed the one million mark. Gaskets from this plant are installed by e-vehicle manufacturers throughout Europe. “This huge number is a great success and an outstanding achievement by the entire local team,” says Marc Nicolas, Director Gaskets at Freudenberg Sealing Technologies in Langres. “It was also a huge challenge, as the plant in Langres had to be completely redesigned to produce the foldable gaskets and the processes had to be adapted accordingly. All this proceeded smoothly during continuous operations. In addition, the order quantities, timings and the design of the foldable gaskets changed several times during the ongoing production process. The fact that we were able to deliver impeccable quality despite all this is thanks to a well-functioning, highly motivated team.”

The pilot line has been partially subsidized by the Public Interest Group (GIP) Haute Marne, the European Regional Development Fund (FEDER), and the Grand Est Region.

Foldable gasket meets highest criteria

By developing the foldable gasket, Freudenberg Sealing Technologies has found a solution that meets customer requirements to the highest degree.

A segmented aluminum carrier with multiple sealing profiles on the outer edge provides strength while also integrating plastic retention fixtures. These are used to attach the gasket quickly and efficiently to the battery housing cover. The carrier segments are interconnected with a continuous sealing profile that is highly flexible. This way it can compensate for small manufacturing tolerances in the housing.

As a result, the foldable gasket helps make the battery system more reliable and durable. Its simple disassembly also makes it easy to service and repair the battery. This benefits both the vehicle owners and the environment: Instead of having to replace the battery, it can be reused.

The foldable gasket is delivered as a single complete unit that doesn’t first have to be assembled from individual elements, which greatly increases the reliability of the installation. Furthermore, battery manufacturers can use fully automated, robotic gasket installation on site. Another significant advantage of this solution is that the metallic inserts ensure high electrical conductivity between the battery housing and cover. This is important for efficient shielding of the electromagnetic fields generated by the current flow in the battery. Otherwise, these fields could interfere with other electronic components in the car.

Materials meet the highest requirements

Despite its large dimensions when installed, the gasket is produced on a small press in Langres. This keeps the amount of energy required for its production relatively low. Additionally, this foldable version facilitates the use of standard-sized packaging solutions, resulting in space savings and, consequently, a reduction in energy consumption during transportation.

“With the foldable gasket technology and the ability of Freudenberg Sealing Technologies to scale the production quickly and robustly, we are showing that this innovative solution plays a key role in ensuring safety and reliability in the fast-growing electromobility market. It’s important that every gasket is developed in close cooperation with our customers. This is the only way for us to meet changing expectations with optimal solutions and be a reliable partner for the industry in the field of modern mobility applications,” notes Frederic Boyer, Head of Marketing Gaskets at Freudenberg Sealing Technologies.

Worldwide production close to customers

The foldable gaskets made by Freudenberg Sealing Technologies use standard elastomers such as silicones and EPDM that meet safety-related flame resistance standards. Combined with an innovative design, these gaskets meet the strictest sealing requirements according to IPX-9K, IPX-7X standards, as well as other global specifications. Moreover, these foldable versions are suitable for all combinations of materials used for the battery cover and housings, such as aluminum, steel and composite materials.

Automobile manufacturers worldwide rely on the innovative solutions from Freudenberg. The foldable gaskets are produced not only at the plant in Langres, France, but also in manufacturing facilities in the USA and Asia for their local markets. After all, Freudenberg Sealing Technologies’ philosophy is to keep delivery routes short and favoring manufacturing where the customer is located. This approach helps limit CO2 emissions generated by transportation.

Ulrike Reich

Head of Media Relations & Internal Communications

Telephone: + 49 (0) 6201 960 5713

ulrike.reich@fst.com chevron_rightNews Service

You can subscribe to the Freudenberg Sealing Technologies news alert service, bringing you the news as soon as they are published. You can always unsubscribe from this service.

Subscribe now! chevron_rightMore news on the subject Automotive & Transportation

News Service

You can subscribe to the Freudenberg Sealing Technologies news alert service, bringing you the news as soon as they are published. You can always unsubscribe from this service.

Subscribe now!