Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

24.10.2024 | Press release

Higher Speed, Less Friction

Weinheim (Germany), October 24, 2024. – For Freudenberg Sealing Technologies, the global market leader for sealing solutions, the advantages of in-wheel motors (IWM) extend beyond the passenger car segment. The company offers a patented sealing geometry to support original equipment manufacturers (OEMs) and manufacturers of electric motors ranging from electric cars to commercial vehicles right at the development stage.

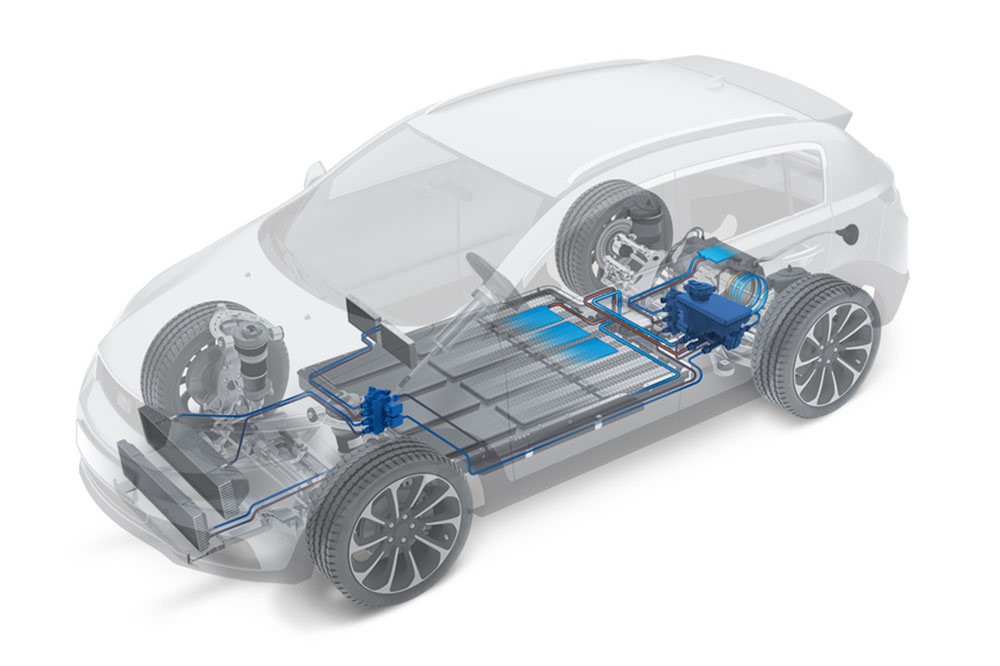

In-wheel motors for electric vehicles offer numerous benefits: Components such as transmissions, brakes, and suspensions can either move much closer to the point of power transmission or be completely eliminated. The decisive advantages of vehicles equipped with IWM include wheel-specific torque control, enhanced comfort and more design space within the vehicle. This results in a better driving experience, greater range and more flexibility for developers.

In-wheel motors are also interesting for buses due to their lower center of gravity, tighter turning radius and higher load capacity. They can also offer added value as a combined trailer drive for e-trucks or as a generator for refrigerated trailers with independent power supply.

“The technical challenges for the seal are mainly to ensure reliable protection against dirt and water while minimizing friction losses,” explains Product Developer Luca Breusa.

Freudenberg Sealing Technologies showcases its expertise as a development partner for IWM manufacturers with a series of innovations, where the seal for IWMs is a particular highlight.

At any speed, the seal provides optimal protection against dirt and water. A key feature of the Freudenberg seal is its dynamic adjustment of sealing effectiveness and friction – which adapts according to the rotational speed of the wheel. This prevents major friction losses.

“As a solution, Freudenberg has positioned the sealing lip in such a way that high contact pressure maximizes sealing performance at low rotational speeds. At higher speeds, both the contact pressure and the friction are significantly reduced by the generated centrifugal forces. Depending on the customer’s requirements, the seal can even be fully lifted off the stator, which also eliminates friction, thus significantly increasing the lifetime of the seal,” Breusa says, describing Freudenberg’s innovation.

The company has developed two significant seal designs: The cassette seal offers a double sealing lip and mating contact surface installed in a closed system, featuring precisely matched materials made of stainless steel and special rubber compounds. The required speed ranges and contamination protection can be scaled. The cassette seal stands out for its long service life and high functional reliability. It is capable of achieving up to 500,000 km and protection class IP67. This makes it a maintenance-free, self-lubricating solution throughout its entire service life.

The second design, a V-seal, works in an open system. Its particularly wear-resistant elastomers with excellent sliding properties, combined with attractive manufacturing costs, create a plug-and-play solution designed for flexible applications.

With these two solutions, Freudenberg expertly bridges the gap between the requirements for high sealing performance and low friction losses. The seal geometry can be scaled to an installation space diameter of up to 530 mm and is adjustable to the respective speed range. This allows the seals to be used in applications ranging from cars to commercial vehicles. “Our recommendation to IWM manufacturers is to involve us as their development partner early in the process. This means that optimal results can be achieved very quickly and prevents additional modification loops,” Breusa says.

Silke Herzog

Senior Manager Corporate Communications

Telephone: + 49 (0) 6201 960 6385

silke.herzog@fst.com chevron_rightNews Service

You can subscribe to the Freudenberg Sealing Technologies news alert service, bringing you the news as soon as they are published. You can always unsubscribe from this service.

Subscribe now! chevron_rightMore news on the subject Automotive & Transportation

News Service

You can subscribe to the Freudenberg Sealing Technologies news alert service, bringing you the news as soon as they are published. You can always unsubscribe from this service.

Subscribe now!