Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

19.09.2024 | Press release

Seals without PFAS?

Weinheim (Germany), September 19, 2024 - The family of per- and polyfluoroalkyl substances (PFAS) is facing intense scrutiny. A reporting rule will take effect in the United States in 2026, while Europe has actually been considering a sweeping, cross-industry ban on these substances since early last year. The implications of such a ban on fluoropolymers would be particularly critical, as a discontinuation of these high-performance materials would drastically impact many industries. But what kinds of challenges would emerge in the search for adequate substitutes? This was the focus of a recent study by the Fraunhofer Institute for Mechanics of Materials (IWM) in cooperation with materials experts from the Freudenberg Group.

Starting in January 2026, U.S. companies that have manufactured PFAS in the U.S. or imported PFAS, or semi-finished or finished products containing PFAS between 2011 and 2022 will be subject to a reporting rule. Individual states are also starting to restrict the use of PFAS or require reporting. The scope and schedules vary significantly from state to state.

On February 7, 2023, the European Chemicals Agency (ECHA) published a proposal for a comprehensive PFAS ban. The affected companies and organizations were given the opportunity to submit feedback on the potential scientific and socio-economic impacts of such legislation by the end of September 2023. More than 4,400 stakeholders provided over 5,600 comments and additional information. Freudenberg Sealing Technologies also contributed to this consultation. “We support the goals of the European Green Deal and the Chemicals Strategy for Sustainability, but are calling for a differentiated, risk-based approach to chemical regulation than is planned for PFAS,” says Dr. Ruth Bieringer, Vice President Technology & Innovation, summarizing the company's position.

Material of choice – but expensive

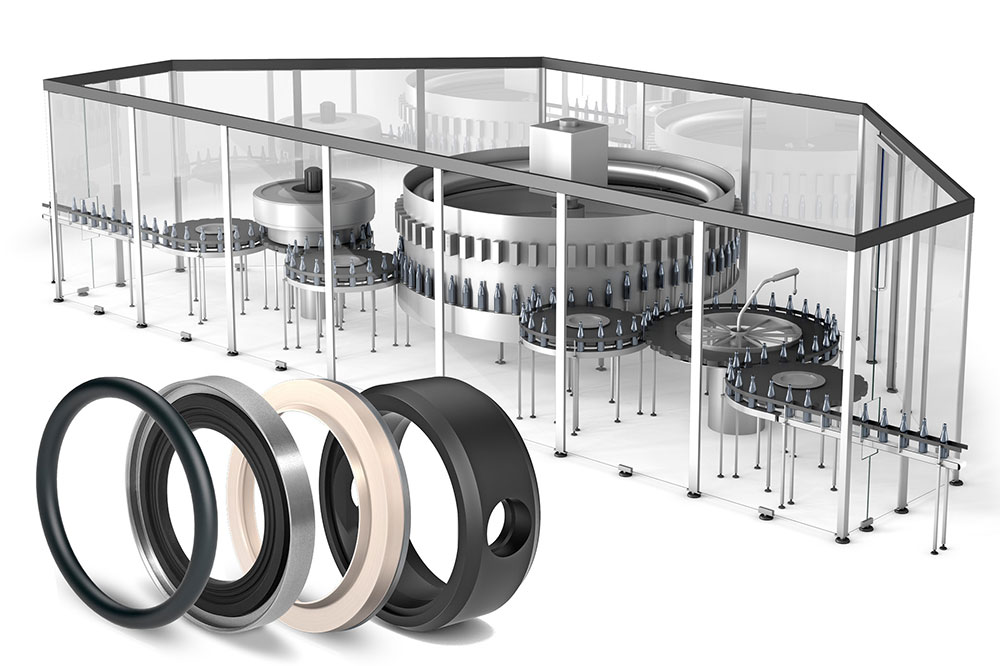

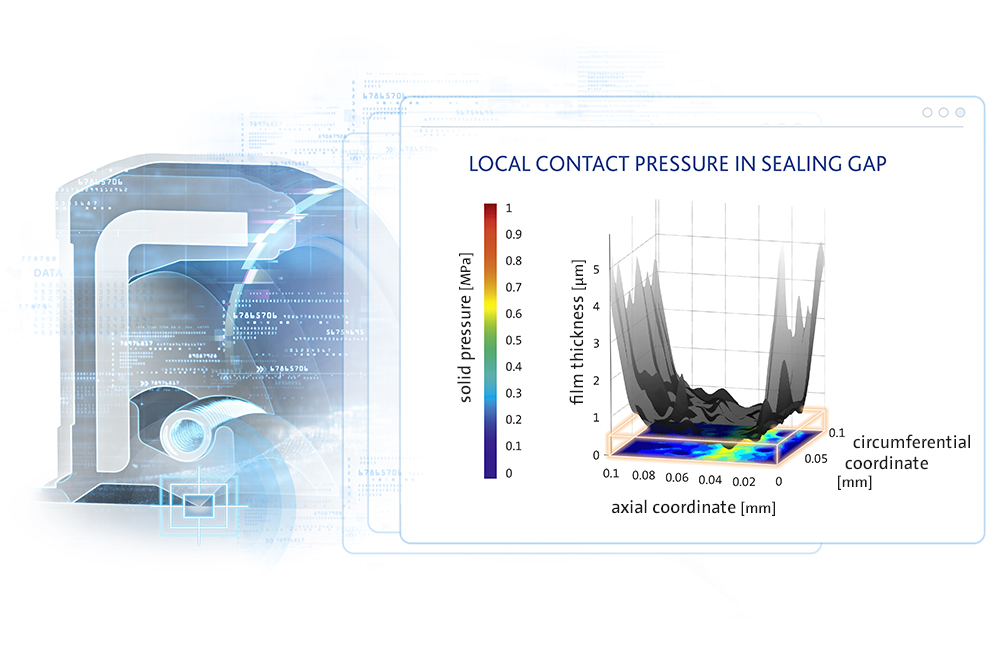

The newly published study by Fraunhofer IWM, titled “Replacement of Polymeric PFAS in Industrial Applications with Harsh Environments,” underscores that fluoropolymers in particular have become indispensable, especially in the sealing industry. The substances are used in numerous applications, including compressors, motors, transmissions, drive systems, as well as in hydraulics and the food and beverage industry. Fluoropolymers are often the “material of choice” when seals must meet multiple requirements – such as excellent high-temperature resistance, lubricant compatibility, or complying with stringent standards for material with food contact. Other examples include high resistance to aggressive cleaning processes and minimal absorption and transfer of aromas. But fluoropolymers are also costly materials, which are generally reserved for applications where their performance exceeds that of more economical polymers.

The authors of the study conclude that a full replacement of PFAS in the sealing industry is currently unfeasible without facing significant losses in material properties, performance, and product longevity. Given the diversity of over 10,000 PFAS compounds, they advocate for a differentiated and fact-based discussion on regulating this class of substances.

Life cycle assessment as a plausible assessment method

Dr. Raimund Jaeger, Head of the Tribology Business Unit at Fraunhofer IWM, explains: “From our perspective, assessing the life cycle of fluoropolymers, which are considered ‘polymers of low concern’, is a credible method for realistically evaluating potential risks to human health and the environment. All stakeholders involved in this study agree that the safe production and disposal of polymeric PFAS is crucial. As long as precautions are taken to avoid harmful environmental impacts, the continued industrial use of fluoropolymers should remain possible.”

A definitive timeline for the introduction of a European PFAS regulation has yet to be established. Nevertheless, the industry is already bracing for potential changes. At Freudenberg Sealing Technologies, the search for alternatives is running at full speed, despite the current indispensability of fluoropolymers: “We have unique expertise in developing polymer materials such as elastomers and thermoplastics for high-performance industrial needs. Our materials have already enabled many breakthrough technologies in the past, and our materials experts are highly motivated to continue creating innovative solutions for future challenges,” Bieringer says.

The complete PFAS study by Fraunhofer IWM is available for download:

Ulrike Reich

Head of Media Relations & Internal Communications

Telephone: + 49 (0) 6201 960 5713

ulrike.reich@fst.com chevron_rightNews Service

You can subscribe to the Freudenberg Sealing Technologies news alert service, bringing you the news as soon as they are published. You can always unsubscribe from this service.

Subscribe now! chevron_rightMore news on the subject Material Expertise

News Service

You can subscribe to the Freudenberg Sealing Technologies news alert service, bringing you the news as soon as they are published. You can always unsubscribe from this service.

Subscribe now!