Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

Piston Seals

The Right Piston Seal for Optimum Performance

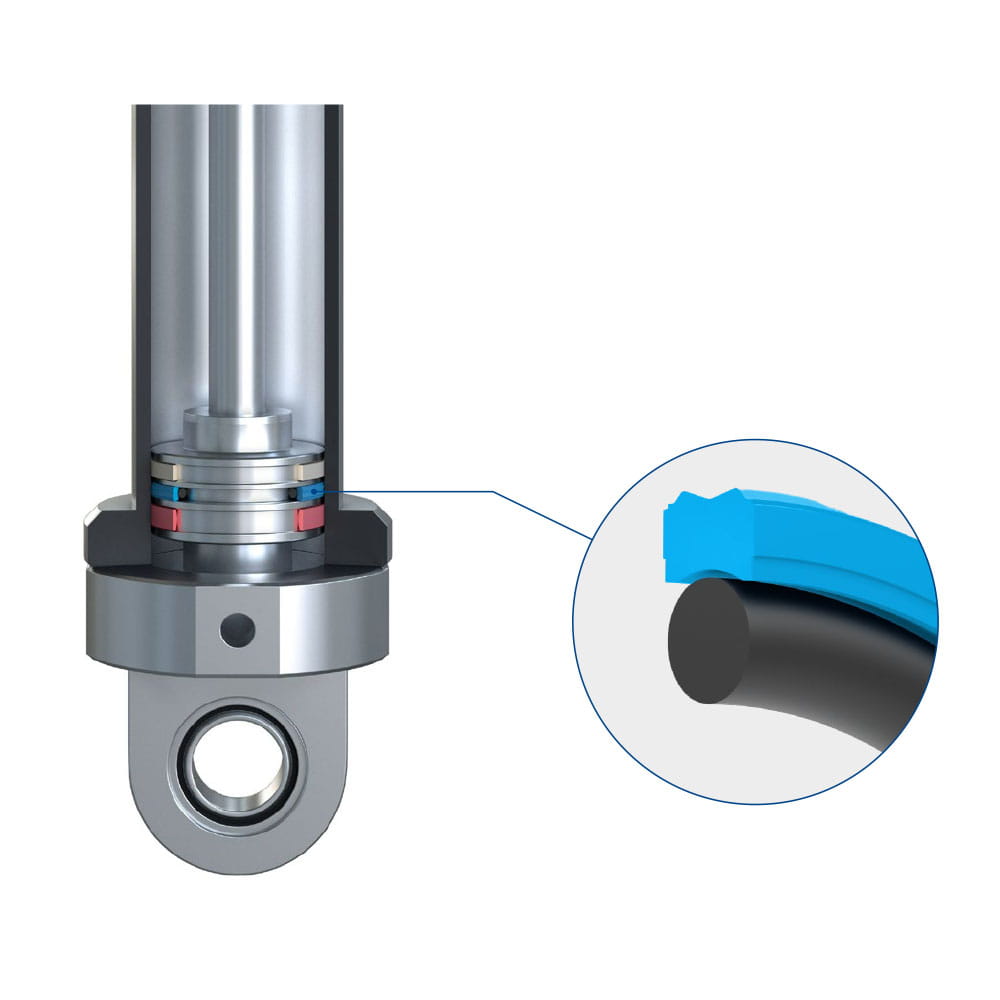

The main function of piston seals is to provide a reliable sealing between the piston and the cylinder tube. It is crucial that the seals fulfill their function even under extreme conditions such as high pressures, strong temperature fluctuations and chemical influences.

In addition to high wear resistance of the seal itself, the gentle, low-friction sliding of the seal on the counter surface of the cylinder tube also contributes to the longevity of the cylinder. Piston seals are an indispensable component in many industrial applications in which hydraulic or pneumatic systems are used. The respective requirements and operating conditions determine the type of piston seal used.

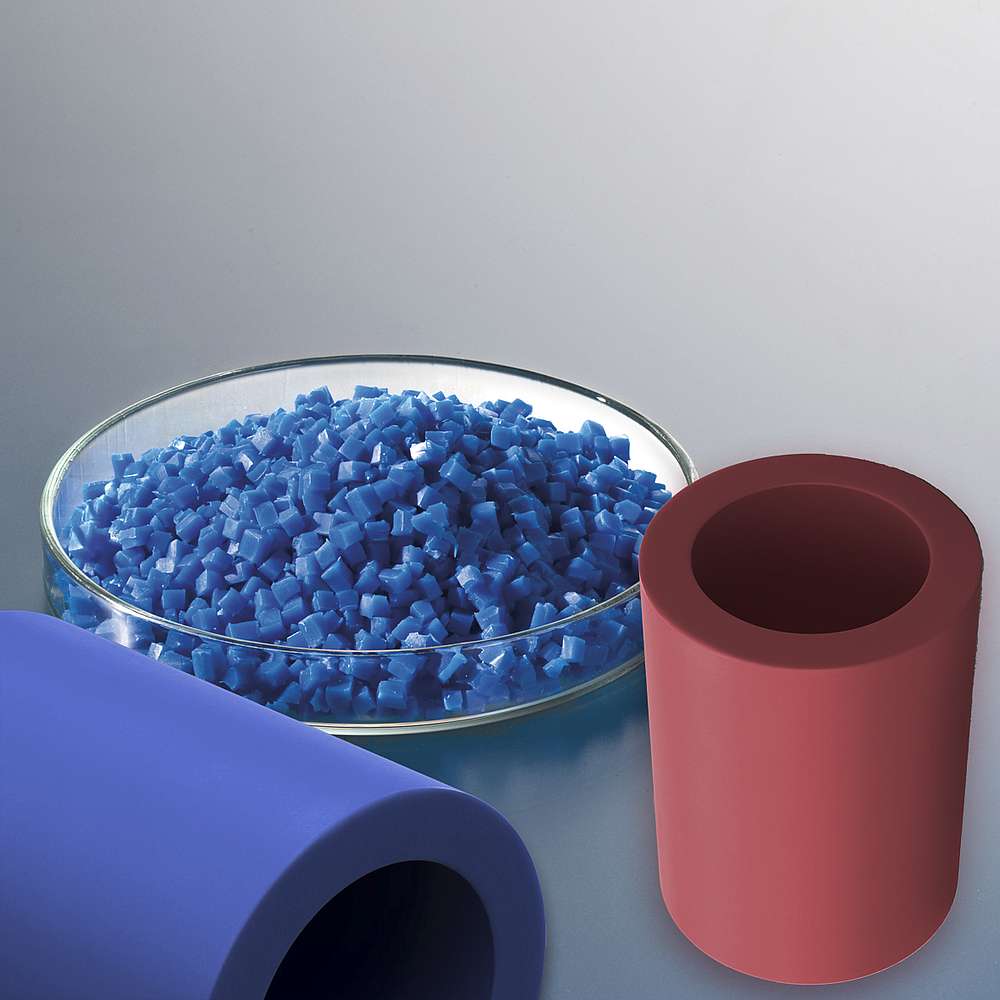

High Functionality Through Suitable Materials

Freudenberg Sealing Technologies uses piston seals in a variety of modern sealing systems that are specially adapted to the respective application conditions and requirements. The choice of material plays a decisive role here.

Materials such as polyurethane, PTFE and polyamides are predominantly used for piston seals, which, in combination with the company's proven geometries, always offer the optimum solution. Extensive test series and millions of customer applications confirm the performance and reliability of our seals.

Omegat OMK PU Made of 98 AU 30500 as an Alternative to PTFE Piston Seals in Mobile Hydraulics

Freudenberg Sealing Technologies presents an innovative solution for sealing pistons in hydraulic cylinders as an alternative to PTFE piston seals. The profile ring of the two-component piston seal is made of the new, hydrolysis-resistant high-performance polyurethane 98 AU 30500 and is supported in its sealing function by an O-ring as a preload element. Learn more on our High-Performance Piston Seals.

The material 98 AU 30500 has further advantages compared to conventional polyurethane solutions, including higher wear resistance, lower abrasion of the counter surfaces, lower dynamic friction and high media resistance. The sum of its properties makes the new material the ideal candidate for replacing PTFE sealing solutions. Learn more about the material.

Piston Seals - Our Most Important Designs Sorted by Material

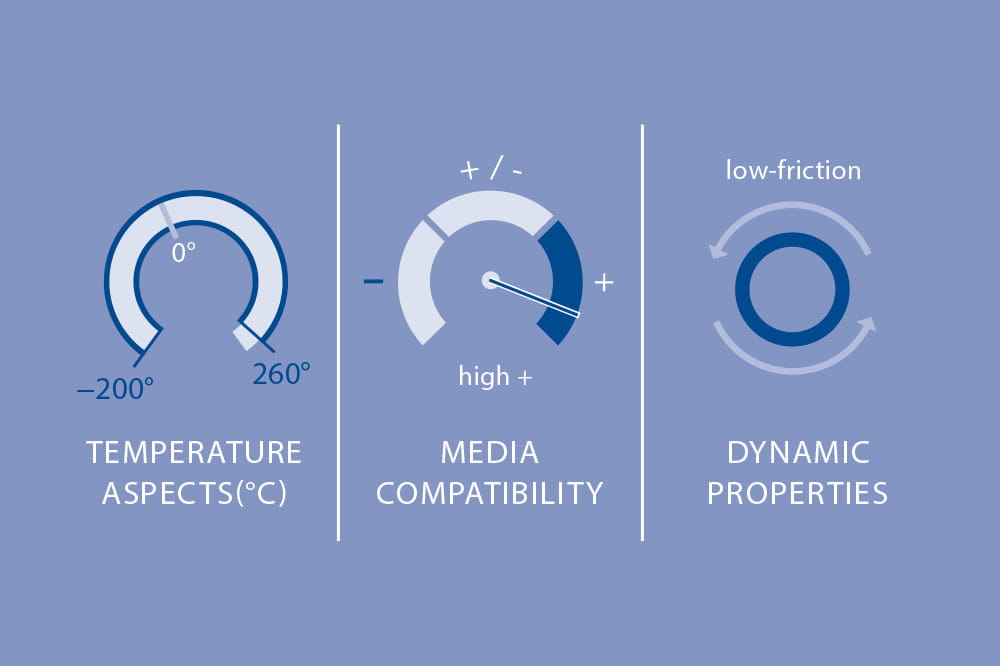

PTFE – Polytetrafluorethylen

PTFE compounds can be used in a wide temperature range from -200 °C to approx. 260 °C. When used as a seal, the additionally required elastomer pre-tensioning element limits the application range to -30 °C to 200 °C.

PTFE compounds are hard, barely elastic and offer very high extrusion resistance. A slight deformation under compressive or tensile load is almost reversible. The excellent sliding properties - even with insufficient lubrication - and its high resistance to media make PTFE the ideal material for a wide range of sealing applications.

Piston Seals – Our Most Important Designs Made of PTFE

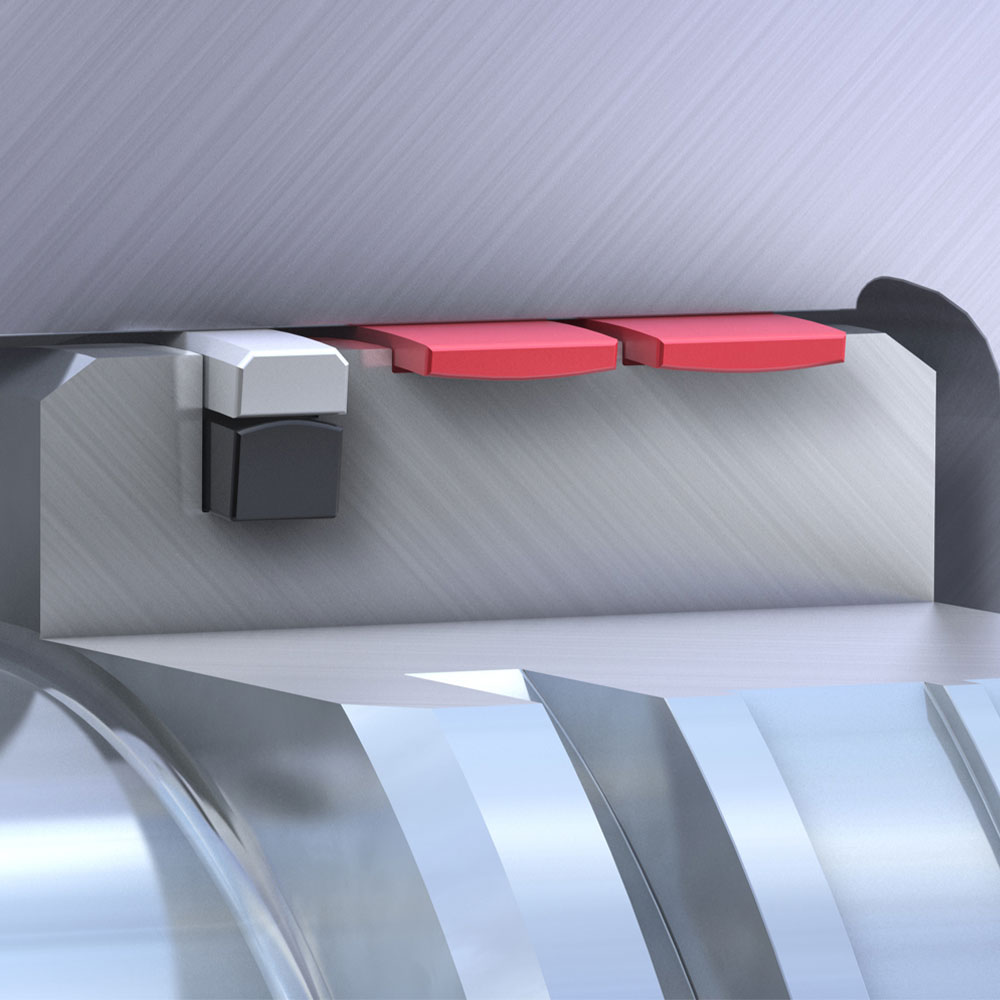

Merkel® Omegat OMK-MR

Two-part compact seal for pressurization on both sides in the standard version. Pressure activation grooves enable quick pressure changes. Suitable for higher operating temperatures in combination with a preload element made of FKM.

Suitable for installation in a housing groove.

-

Proven seal of the highest quality and functional reliability

-

Highly extrusion-proof and pressure-resistant

-

Very good abrasion resistance, low friction, stick-slip-free

Merkel® Omegat OMK-S

Two-part compact seal for pressurization on both sides in the heavy-duty version. The profile ring used as a preload element is torsion-proof and highly resilient. Pressure activation grooves enable fast pressure changes. Suitable for higher operating temperatures in combination with an FKM preload element.

Suitable for installation in a housing groove.

-

Proven seal of the highest quality and functional reliability in heavy-duty applications

-

Highly extrusion-proof and pressure-resistant

-

Very good abrasion resistance, low friction, stick-slip-free

PU – Polyurethane

Polyurethane has been the ideal material for seals - especially for hydraulic applications - for more than 60 years. Its proficiencies are, in particular, its high mechanical strength, ideal elasticity, excellent tear and abrasion behavior and its good media resistance. Customized solutions are available for a wide range of applications, covering low temperatures of -50°C and high temperatures of up to 120°C, offering special resistance requirements, e.g. hydrolysis and special certifications.

In particular, to increase the lifespan, we use special mixtures of hard polyurethanes for piston seals, such as 98 AU 928 or 98 AU 30500. Polyurethanes like 98 AU V211 or 98 AU 21440 are predominantly used as machined piston seals in heavy industry applications.

Piston Seals – Our Most Important Polyurethane Designs

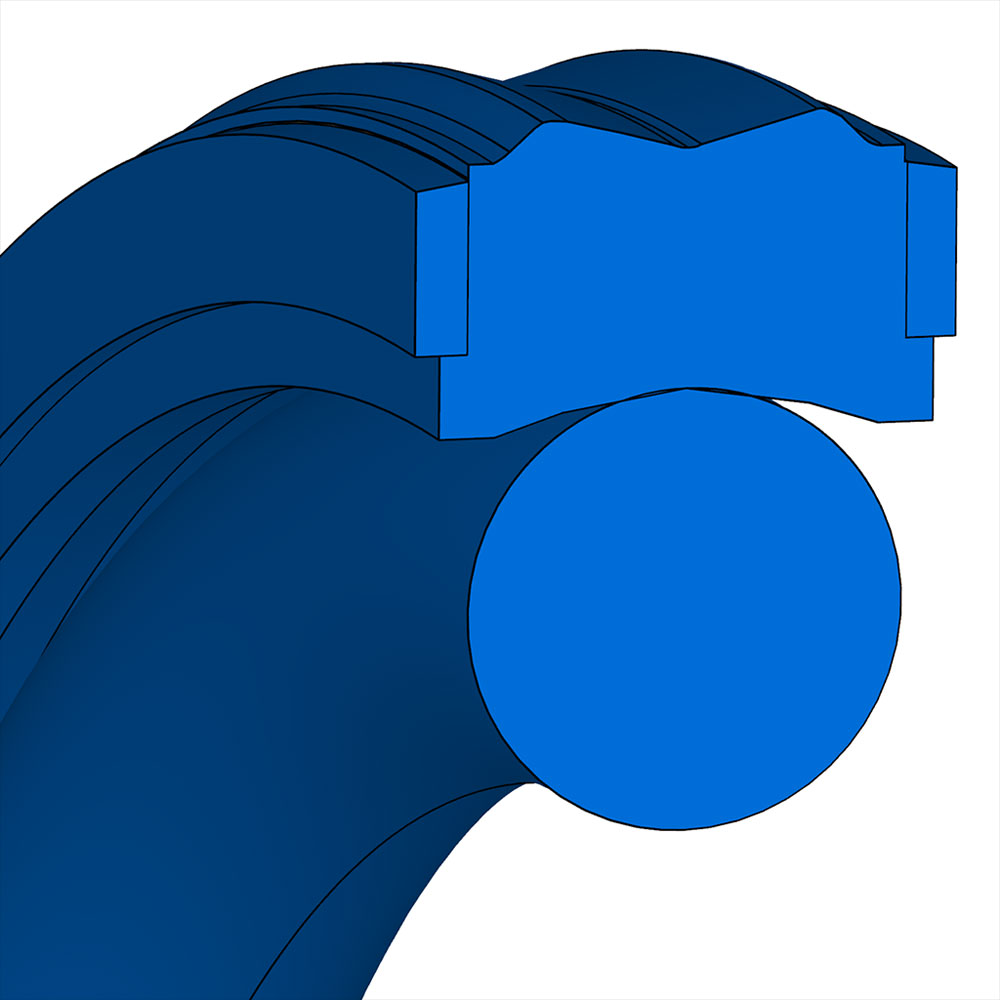

Merkel® Omegat OMK-PU 30500

The two-part piston seal made of the new hydrolysis-resistant high-performance polyurethane combined with an O-ring compression element serves as a possible alternative to piston seals with a PTFE sliding ring and fits into existing standard PTFE ISO installation spaces.

The TPU sliding ring can be combined with different O-ring materials depending on the application and thus ensures maximum tightness, durability or chemical resistance, for example, even in demanding applications.

-

Interchangeable with standard PTFE ISO installation spaces (ISO 7425-1:2021-02)

-

No recalibration required after installation

-

Robust against damage (pipe surface and assembly process)

-

High physical properties (resistant to gap extrusion and wear)

-

Free of PFAS restrictions compared to PTFE solutions

-

Very low leakage values

-

Low friction due to hydrodynamically optimized sealing geometries

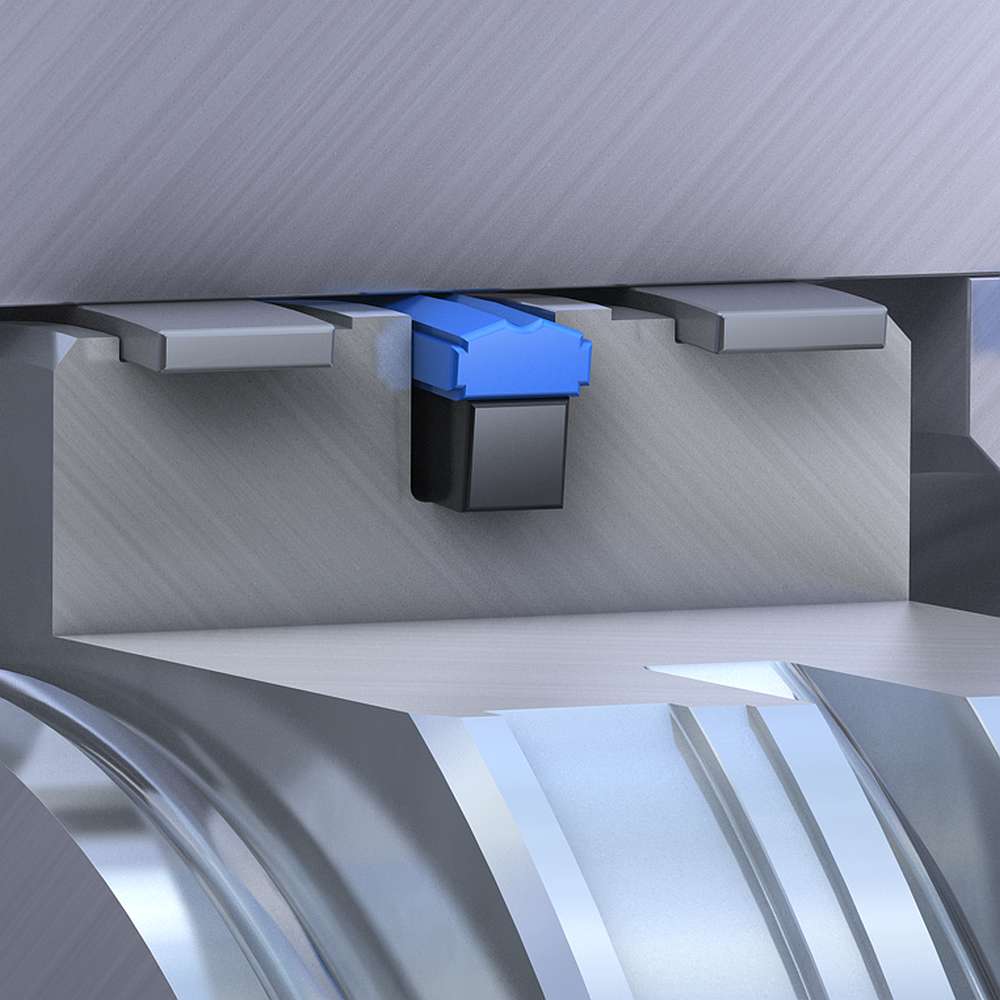

Merkel® Omegat OMKU-MR

Machined piston seal with a focus on applications in heavy industry.

This two-part compact seal is suitable for pressurization on both sides. Pressure activation grooves enable quick pressure changes. Suitable for installation in a housing groove.

-

Excellent pressure and extrusion resistance

-

High abrasion resistance

-

Low friction, stick-slip-free

-

For standardized installation spaces in accordance with ISO 7425/1. Rod Ø in accordance with ISO 3320

Simko 300

The double-acting two-part Simko 300 compact seal consists of a profiled ring with distinctive sealing edges and a rectangular contact pressure element to generate uniform preload.

Advantages:

-

Good static and dynamic tightness

-

Low friction, smooth movement even at low sliding speeds

-

Contact pressure element with rectangular cross-section, high resistance to torsion in the installation space

-

Standardized installation spaces based on ISO 7425

-

Low axial installation height

PA – Polyamide

Polyamides offer high strength, rigidity and toughness with good chemical resistance and processability. Polyamides have high wear resistance and good sliding properties.

The mechanical properties can be further improved by fiber composites with glass or carbon fibers, so that strength and impact strength can be adapted to the application.Polyamides are characterized above all by their high wear resistance, good damping capacity, emergency running properties and low creep tendency.

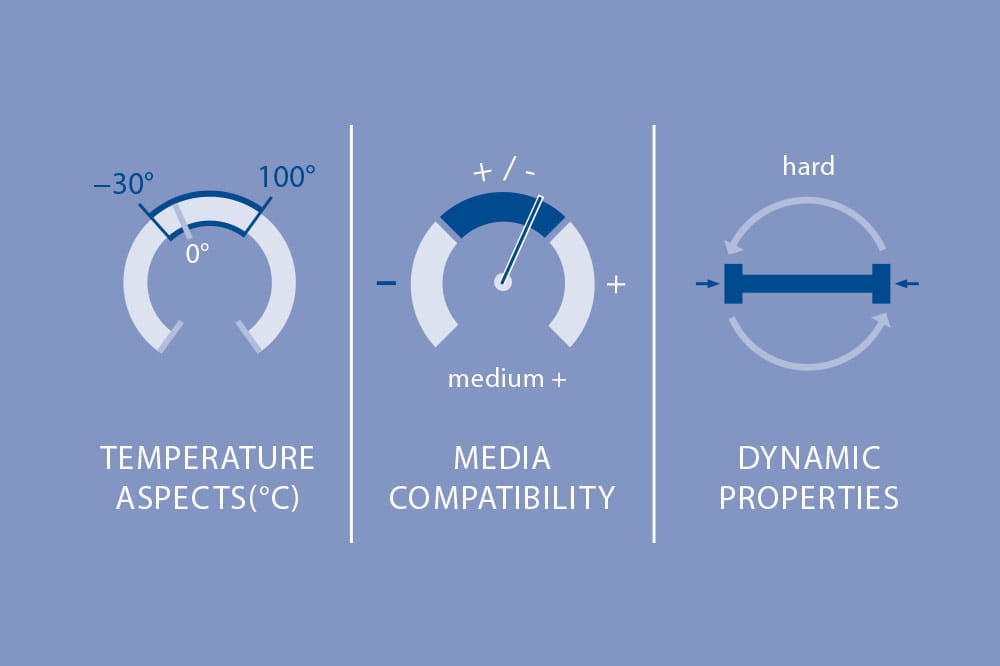

Thanks to its strength values, PA is particularly suitable for use in demanding hydraulic applications with high working pressures as well as pressure peaks and covers temperatures from -30°C up to 100°C.

Piston Seals – Our Most Important Polyamide Design

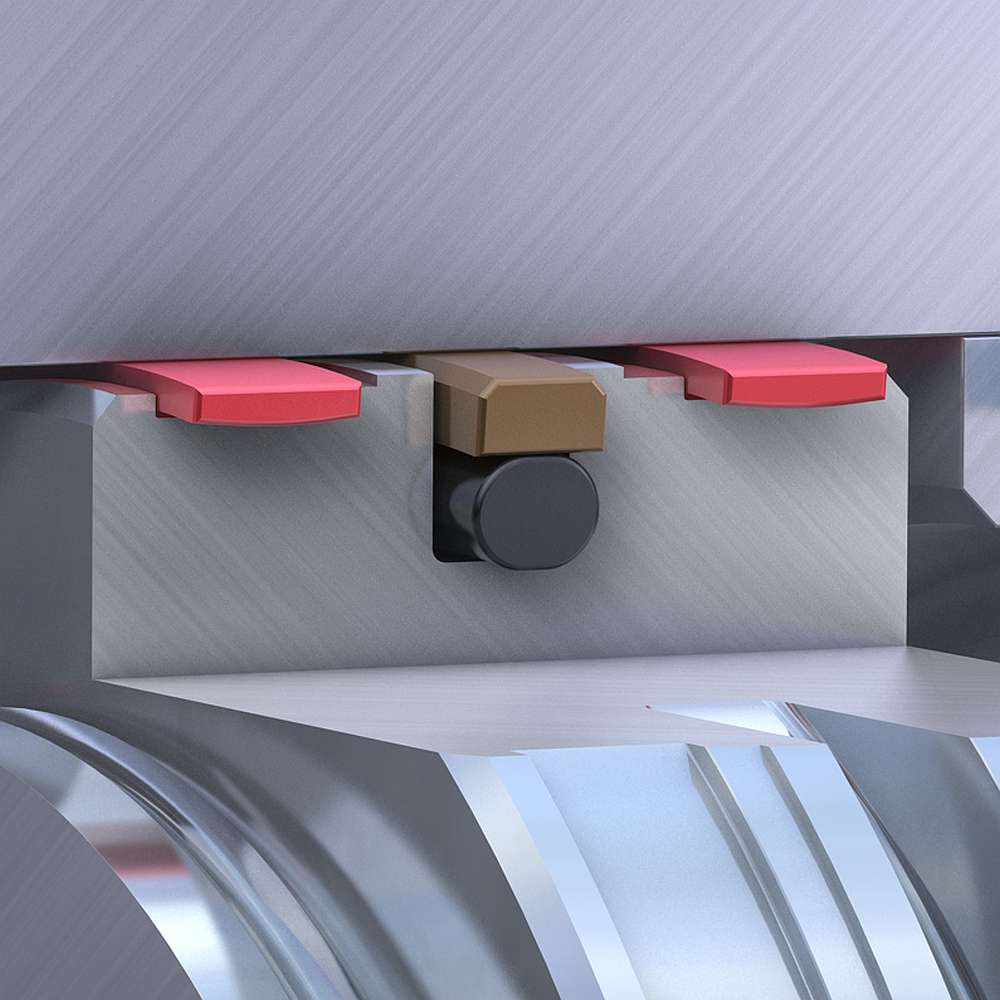

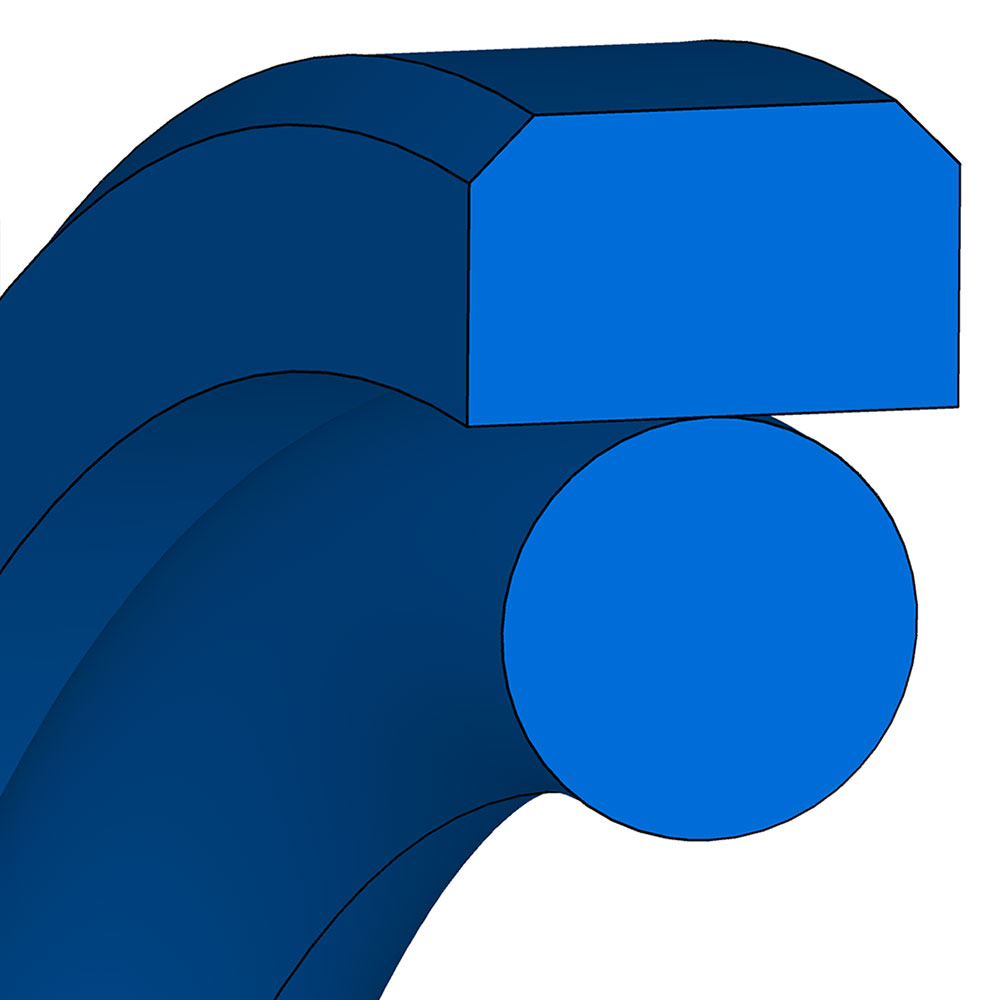

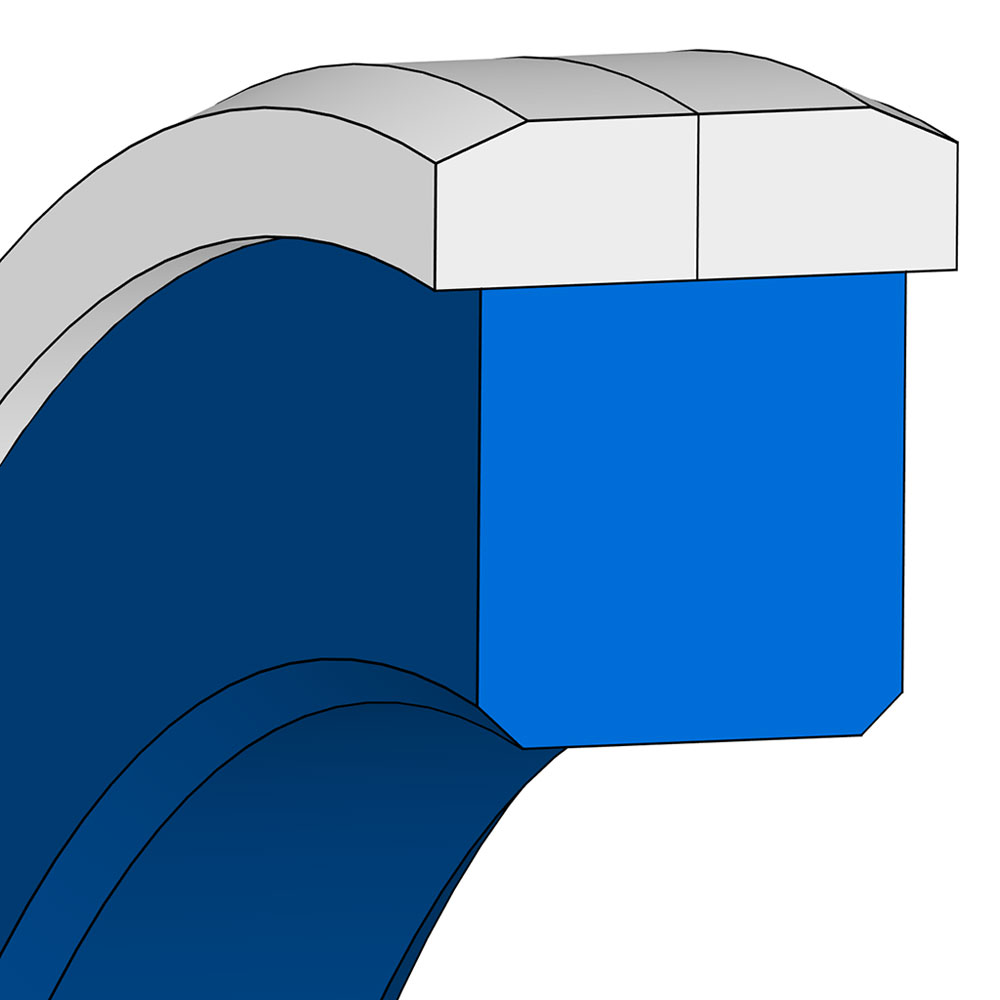

HDP330

The HDP330 heavy duty piston seal is particularly suitable for the heaviest applications and especially high pressures. The two-parted seal set consisting of a PA sliding ring and an elastomer profile ring as a preload element fits into standardized installation spaces in accordance with DIN ISO 7425-1 and offers the following advantages.

-

Well suited for extreme operating conditions, including working pressures of up to 60 MPa

-

Particularly robust, e.g. when sliding over holes

-

Stepped cut in the sliding ring simplifies installation in closed piston groove

-

Sliding speed 0.8 m/s

-

For pressurization on both sides

Further versions and special designs in our Product Catalog

Selected designs can be compared there with their application parameters. This facilitates the final selection of a suitable seal for the respective application.

View Product Catalog open_in_newRelated Products of the Dichtomatik Brand

Premium Freudenberg brand products meet the highest quality requirements and are suitable for all segments and applications. Complementing this, Dichtomatik brand products are a good solution for moderately demanding, non-safety-critical applications.

View Dichtomatik Piston Seals open_in_newHydraulic Selector

Are you searching for sealing solutions for your hydraulic application?

View Hydraulic Selector open_in_new

3D Animations

Discover our innovative sealing solutions for use in Hydraulic Applications

in the new 3D animations!

Join Us!

Experience Freudenberg Sealing Technologies, its products and service offerings in text and videos, network with colleagues and stakeholders, and make valuable business contacts.

Connect on LinkedIn! open_in_new