Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

Micro Seals

Micro Seals: Tailored Precision and Reliability in the Smallest of Formats (For Modern Medical and Laboratory Technology)

Micro Seals stand for precision and reliability and are of crucial importance in modern medical and laboratory technology. These tiny, extremely precise components prevent leaks and ensure that devices function reliably and efficiently. They are used primarily in fluid handling valves, pumps and mixers, as well as small electric motors.

Freudenberg Sealing Technologies offers a broad range of micro-seals and components that are specially designed for the most demanding applications and manufactured in Germany. We have years of experience in the development and production of customized micro seals with dimensions of up to about 20 mm. Our extensive materials expertise, combined with our experience in the production of advanced tools and our in-depth knowledge of the manufacturing processes, make us a leading supplier of reliable micro seals.

Find out more about our high-precision Micro Seals.

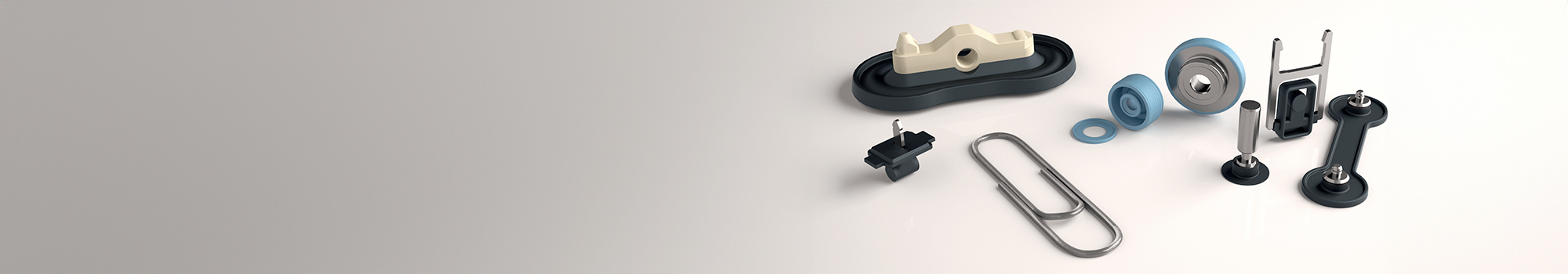

Micro Seals – Maximum Variety in the Smallest Format

Our micro seals are developed specifically for each customer and their respective application. Every component is the result of close collaboration with our customers to overcome their specific challenges and requirements. The components presented here are therefore only examples of the countless possibilities for using our high-precision sealing elements and components in a wide variety of devices and systems to ensure maximum accuracy and reliability.

Customized micro seals: Versatile solutions for demanding applications

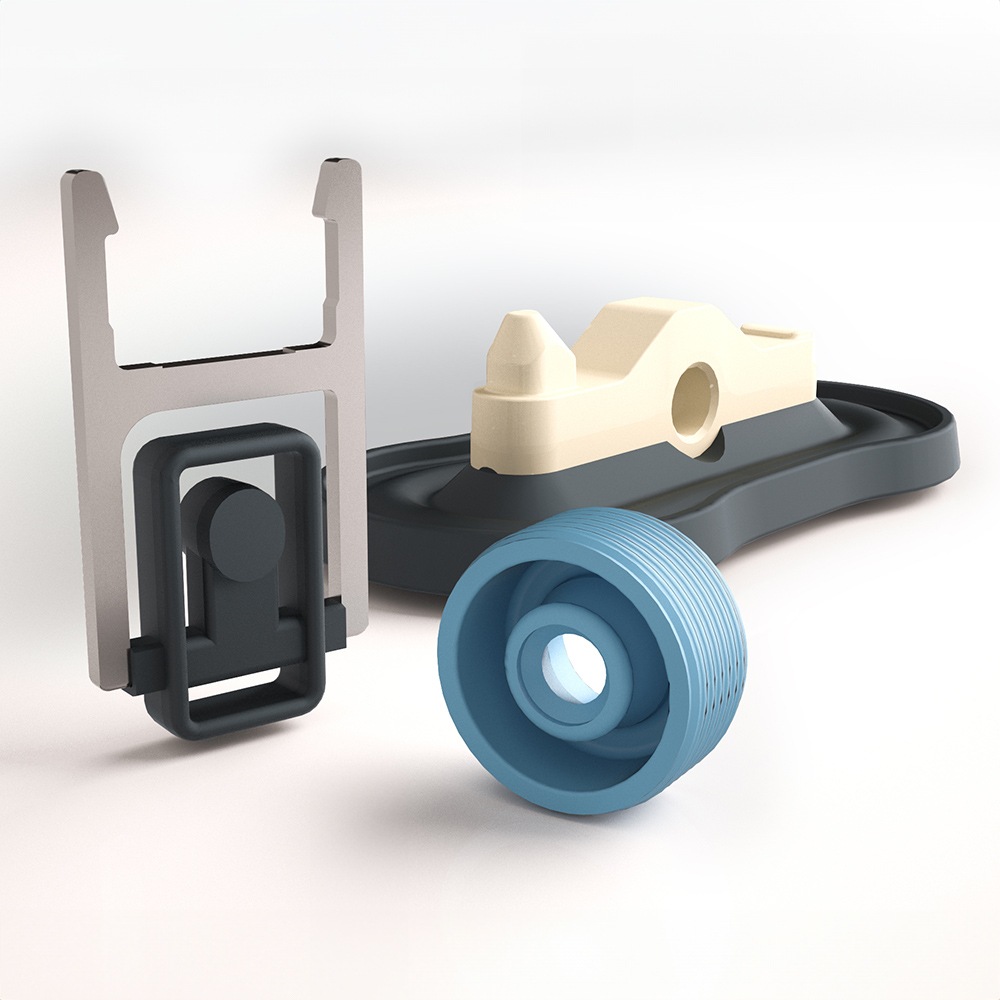

Micro-Simmerring®

It reliably seals rotating shafts of 1-3 mm at 20,000 rpm, withstands extreme temperatures and media. It also minimizes friction and maintenance costs.

Rocker Valves

They precisely control liquid and gas flows in 2- and 3-way microfluidic valves.

Flipper Valve Seal

These high-precision seals made of FFKM/FKM for microfluid valves provide reliable sealing at 7 bar for up to 10 million switching cycles with minimal tolerances and burrs.

Brake and Seal Disc

Specially developed for sealing dental drills, the Brake & Seal Disc is not only a dental seal, but also stops their rotation at up to 350,000 rpm in the shortest possible time for safe dental treatment.

Hammer Seal

These sealing components provide static and dynamic sealing functions, are made of chemically resistant FFKM, can withstand up to 7 bar and over 50 million switching cycles in complex 2/2 and 3/2-way solenoid valves.

Valve seat seal

Valve seats for axial solenoid valves ensure reliable sealing and precise control of the medium. They prevent leakage and are crucial for safe operation in applications such as medical technology and industrial automation.

“Dogbone” Elastomer Composite Seal

Elastomer composite Seals in the shape of a dogbone are composite Seals made of stainless steel and rubber that are used in 2/3-way solenoid valves. They are produced over 500,000 times a year and are universally suitable for various media thanks to FFKM. Also used in 2/3-way solenoid valves, this seal offers a high degree of reliability and durability.

Valve Seal

They control gas flows in medical devices. In anesthesia machines, they play a key role in the function and control of the solenoid valve system, which regulates the flow of anesthetic gases.

Find out more about our Micro Seals...

...and discover how we can optimize your application.

Get Expert Advice TodayWhat Are Micro Seals?

Micro seals are extremely small, high-precision sealing elements used in devices and systems that require the utmost accuracy and reliability. These components can be made of elastomers or elastomer-based composite materials and are used in a wide range of applications, from medical devices and laboratory instruments to industrial applications. Their primary function is to seal fluids or gases while maintaining the integrity of the system.

Micro seals fulfill various sealing tasks:

- Dynamic Sealing Pads: These parts provide a movable seal suitable for applications such as rotating or reciprocating motion.

- Diaphragms (Diaphragm): They are used to create flexible but tight separating layers, which are required in valves or pumps, for example.

- Static Sealing Bead: These seals are designed for applications where a firm, unchanging seal is required.

Depending on the specific requirements, various materials can be used to manufacture these micro Seals, including:

- EPDM, FKM, FFKM

Elastomers with outstanding chemical resistance, high temperature resistance and excellent aging and ozone resistance. - Thermoplastics (e.g. PA6.6 GF, PEEK), metals (e.g. steel, aluminum)

High-performance materials that often serve as base materials for elastomer-based composite concepts to provide additional strength and durability.

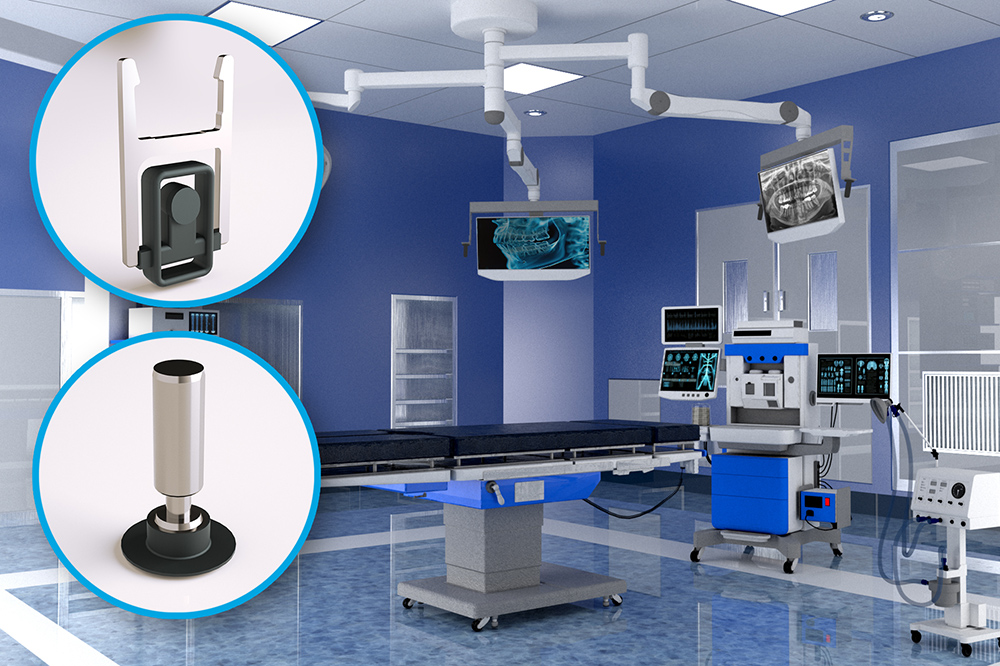

Micro Seals in the Clinical Environment – Precision and Reliability in Every Situation

Our seals and micro seals play a crucial role in the clinical environment. They ensure that important devices and systems function reliably – from the reception area to the operating room.

Micro seals from Freudenberg Sealing Technologies are a byword for the highest quality and reliability. Our products are the result of extensive research and development and a deep understanding of our customers' requirements. Find out more about our micro seals and discover how we can optimize your applications.

Find out more about our Micro Seals...

...and discover how we can optimize your application.

Get Expert Advice TodayMicro Seals + Unique Material Know-How = ❤️🔥

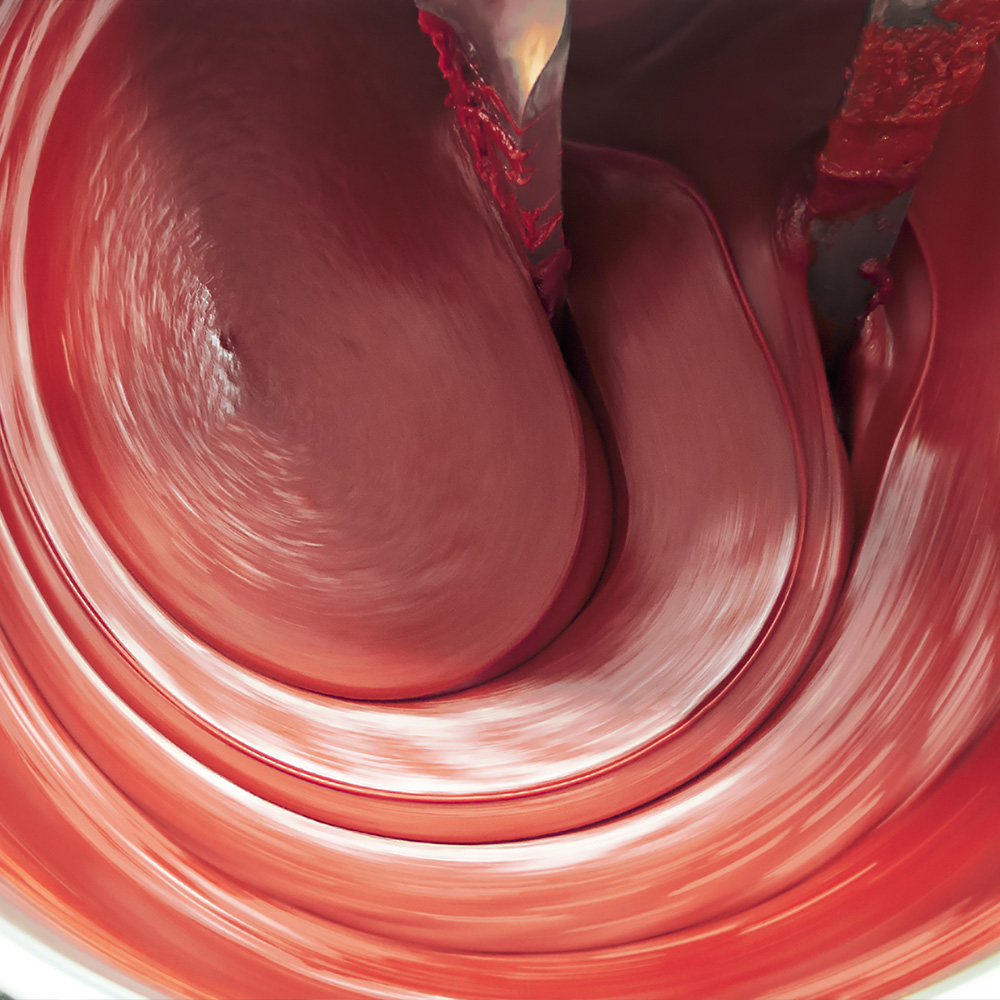

The unique material know-how of Freudenberg Sealing Technologies is the best basis for selecting the right material. Depending on the requirements, FKM, FFKM or EPDM are used, each of which offers special properties:

FKM

FKM has excellent resistance to oils, fuels, chemicals and high temperatures of up to 250°C.

FFKM

FFKM is characterized by extreme chemical resistance and temperature resistance up to 327°C, making it ideal for use in aggressive environments. FFKM also has excellent aging resistance and retains its mechanical properties even under long-term exposure to high temperatures and aggressive chemicals.

EPDM

EPDM, on the other hand, is particularly resistant to ozone, UV radiation, hot water and steam. It can be used in a wide temperature range from -50°C to +150°C, in which EPDM also has good resistance to aging.

The Expertise of Freudenberg Sealing Technologies

Production Reichelsheim

We have decades of experience in the development and manufacture of sealing solutions. Our expertise in materials science, particularly in FFKM, FKM and EPDM, enables us to develop seals that can be used in a variety of chemicals and other media.

Our micro seals are characterized by their high precision, reliability and durability. Thanks to our advanced materials science and manufacturing technologies, we can offer seals that meet even the most demanding requirements.

Our Services for Micro Seals

Join Us!

Experience Freudenberg Sealing Technologies, its products and service offerings in text and videos, network with colleagues and stakeholders, and make valuable business contacts.

Connect on LinkedIn! open_in_new