Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

Micro Seals in the Dental Clinic

Micro Seals in Dental Clinics: Precision in the Smallest of Formats

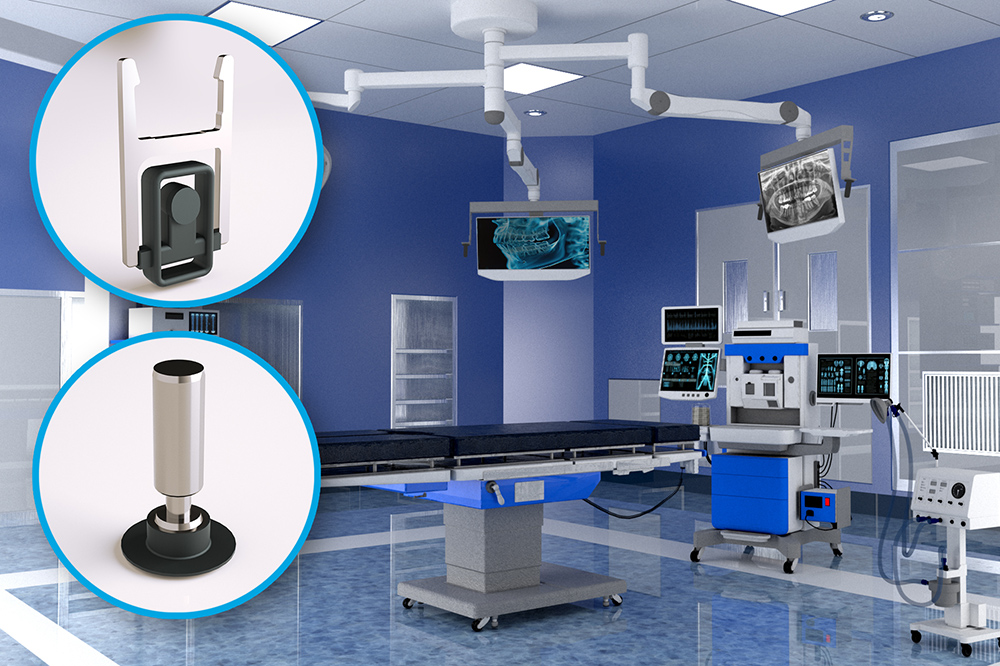

In a modern dental clinic, precision, safety and hygiene are of the utmost importance. Every component, large or small, contributes to the smooth and efficient running of the treatment. Micro seals play a crucial role in dental equipment. Freudenberg Sealing Technologies specializes in the development and production of these essential components and offers high-performance solutions that are precisely tailored to the requirements of modern dental treatment equipment. Our Micro seals ensure safe operation and help maintain the high hygiene standards in dentistry.

Micro Seals in Modern Dental Treatment Units

Micro seals are used in various components of modern dental chairs, where they are crucial for precise control, movement and functionality. Here are some of the areas in which micro parts play an important role:

Water as a Central Component of Dental Treatment

Water is used for a variety of purposes in dental treatment to increase the efficiency of the treatment, to ensure hygiene and to increase patient comfort. It is used for various purposes:

- Cooling: Rotating instruments such as dental drills generate significant heat that could damage dental tissue. To avoid this, water is continuously sprayed onto the treatment site to lower the temperature and prevent overheating.

- Cleaning and rinsing: During treatment, small particles such as enamel, dentin or old filling materials are removed. Water helps to flush these particles away and keep the dentist's view of the treatment area clear.

- Patient comfort: Regular rinsing with water during treatment helps to keep the patient's mouth clean and reduces the unpleasant feeling of dryness that can result from keeping the mouth open during longer treatments.

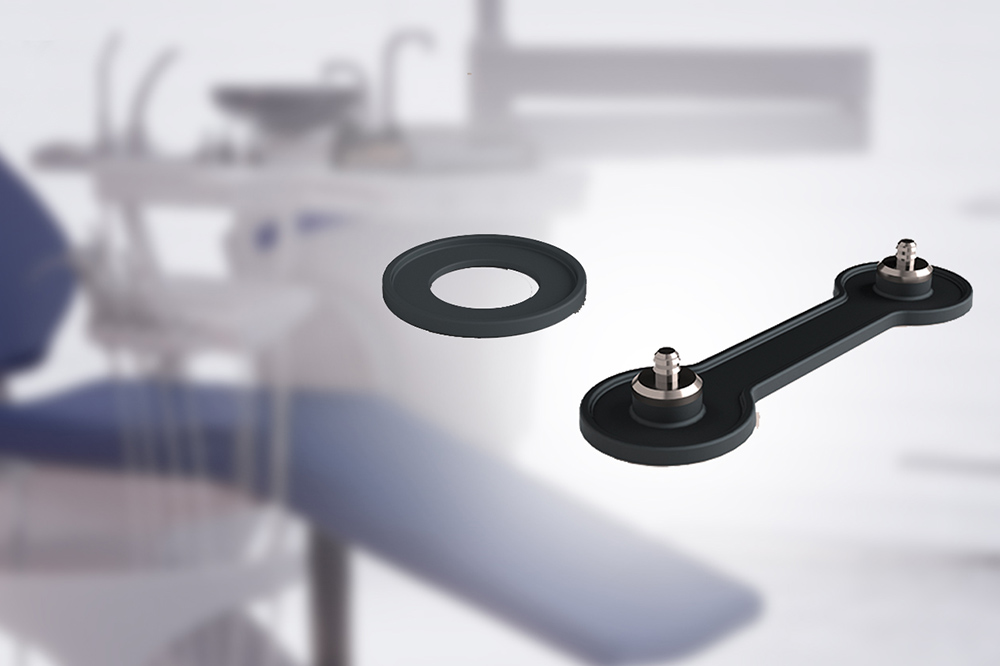

The “Dogbone” From Freudenberg Sealing Technologies

Micro Seals for 2/3-Way Solenoid Valve Applications Control the Flow of Water

The so-called “dogbone”, a specially developed micro-elastomer composite part for 2/3-way solenoid valve applications, ensures that the water supply in dental equipment is controlled precisely and reliably. The name “dogbone” refers to the shape of the valve component, which strongly resembles the popular dog snack. This specific shape makes it possible to switch two fluid channels (left and right) in a space-saving way, which is particularly advantageous in compact dental equipment. The “dogbone” works similarly to a rocker valve, but due to its shape and functionality, it is optimally suited for tight installation spaces.

Thanks to the use of high-quality elastomers such as EPDM, FKM and FFKM, the “dog-bone” is universally applicable and resistant to various chemical influences. This makes it ideal for use in water-bearing systems that regularly work with different fluids and pressure conditions.

All the Advantages of the “Dog-Bone” at a Glance

-

Space-saving design

For efficient use of the installation space. -

High durability

The high-quality elastomers (EPDM, FKM and FFKM) are extremely resistant to chemical influences and media. -

Narrow tolerances

Ensure reliable performance and precision. -

Mass production possible

(> 500,000 units/year)

Brake and Seal Disk: Precise Braking and Sealing for Dental Drills

The dentist's drill is one of the most important tools in dental treatment. Complete control over the drill is essential to work accurately and safely. This is where the brake and seal disk from Freudenberg Sealing Technologies comes into play.

Development and Function of the Brake and Seal Disk

The brake and seal disk is a special lip seal that functions both as a brake and as a micro seal in dental drills. It was developed in close collaboration with leading manufacturers of dental drills. The disc enables the drive shaft to be stopped quickly at speeds of up to 350,000 rpm: as soon as the dentist lifts the pedal, the drill stops in less than a second. At the same time, the brake and seal disc acts as a non-return valve to prevent media from being drawn back. It is resistant to water, disinfectants, air and repeated sterilization, making it a reliable micro-component in demanding dentistry.

All the Advantages of the Brake and Seal Disc at a Glance

-

Safety and control

The rapid stop of the drill minimizes the risk of injury and increases precision during work. -

Hygiene

The sealing function of the brake and seal disc prevents water and disinfectant from flowing back, thus contributing to hygiene in the treatment room. -

Reliability

Even at high speeds of up to 350,000 rpm, the brake and seal disc remains reliable, ensuring safe and efficient treatment. -

Precision and Quality

Lip thicknesses of just a few tenths of a millimeter with a manufacturing tolerance in the hundredths range are indicative of the highest quality.

The Ideal Material for Dental Applications

Selecting the right material is crucial for the function and durability of micro seals in dentistry. Freudenberg Sealing Technologies has unique materials expertise and a broad portfolio of materials that have been specially developed for use in dentistry and medical technology. These include, in particular, FFKM, FKM and EPDM. Depending on the various requirements, the performance of the respective application can be optimized by selecting the optimal material. FFKM, for example, offers the highest chemical resistance and is ideal for use in anesthesia machines where aggressive chemicals are used. FKM, on the other hand, is particularly temperature resistant and is ideal for use in dental drills that are exposed to high speeds. EPDM is convincing due to its ozone and aging resistance and is therefore often used in water-bearing systems.

This expertise in materials, coupled with our experience in the development and manufacture of micro seals, makes Freudenberg Sealing Technologies a preferred partner for medical technology.

Would You Like to Learn More About Our Customized Solutions for Use in Dental Clinics and Practices?

Our expertise in material selection and product development ensures that your equipment works reliably and efficiently.

Get Expert Advice TodayHigh Safety, Ergonomic and Hygiene Standards

Dentist chairs are subject to a variety of requirements and classifications in order to meet the high standards in dental practice. These requirements relate to safety and ergonomics as well as hygiene standards and technical specifications. Here are some of the most important aspects:

Medical Device Regulation (MDR)

In the European Union, dental chairs must comply with the provisions of the Medical Device Regulation (MDR). This regulation sets strict requirements for the safety, performance and quality of medical devices. For example, dental chairs must be tested for biocompatibility to ensure that they do not have any harmful effects on patients or users.

Iso Standards

-

ISO 13485: This standard specifies the requirements for quality management systems for the manufacture of medical devices, including dental units.

-

ISO 6875: This standard, which is specific to dental chairs, specifies the requirements for safety, mechanical resistance, stability and hygiene. It also defines test methods for mechanical resistance and safety requirements for moving parts.

-

ISO 7494-1: This standard covers the requirements for the mechanical stability, electrical safety and biocompatibility of dental equipment.

Ergonomic Requirements

Dentists' chairs must be designed to provide maximum comfort for both patients and dentists. Ergonomic requirements according to DIN EN 60601-1-4 include the chair's adaptability to different positions, supporting the patient's body during treatment and reducing physical strain on the dentist.

Hygiene Standards

The hygiene standards for dental equipment, including dental chairs, are regulated in various standards and guidelines. One of the most important standards is DIN EN ISO 17664. This standard defines the requirements for the processing, care and sterilization of medical devices, including dental equipment. It covers aspects such as cleaning, disinfection and sterilization to ensure that the devices are hygienically safe and do not pose a risk of infection.

In addition, in Germany there is the Robert Koch Institute (RKI) guideline for infection prevention in dentistry, which provides specific recommendations for hygiene in dental practices. This guideline is often used in conjunction with the Medical Device Operator Ordinance (MPBetreibV) and the DIN EN ISO 14937 standard, which defines requirements for the validation and routine monitoring of sterilization processes for medical devices.

Electrical Safety

Because modern dental chairs are often electrically operated, they must comply with electrical safety standards, such as IEC 60601, which sets out the basic safety requirements for electrical medical equipment. These standards ensure that the chair can be operated safely at different voltages and that there is no danger to the patient or medical staff.

Risk Class Classifications

Dental chairs are generally classified as Class I or Class IIa medical devices, depending on whether they contain additional features such as integrated medical devices (e.g. X-ray machines). The classification influences the type and extent of testing that the chair must undergo before market approval.

Water quality

Additional water quality requirements apply to treatment units that have water supply systems. The materials used must be suitable for contact with drinking water, and the system must be designed so that it does not introduce contaminants into the water. Specially developed seals and valves, such as the elastomer composite part known as the “dog bone” from Freudenberg Sealing Technologies, play an important role in ensuring the safety and hygiene of the water supply.

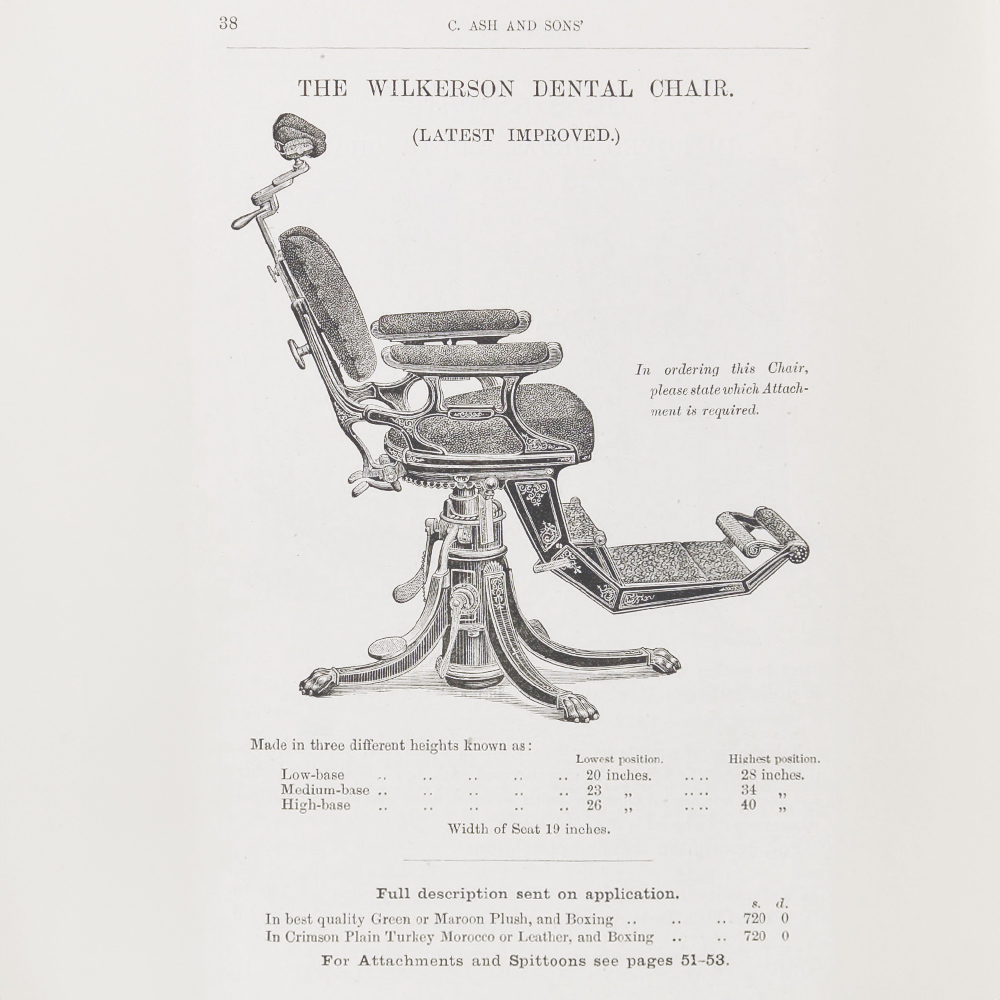

The Evolution of the Dental Chair

The dental chair is the centerpiece of the treatment room. Over the years, it has evolved from a simple seat to a highly complex, adjustable dental treatment unit with a variety of dental instruments.

Stricter Requirements for Drinking Water Hygiene

With the increasingly stringent drinking water guidelines that will come into force from 2025, it is becoming more and more important to ensure impeccable drinking water hygiene. The revised guideline requires that materials that come into contact with drinking water meet the strictest requirements.

Our micro seals, such as the “dog bone”, are made of highly durable materials such as EPDM. This material is not only extremely resistant to high temperatures and aggressive cleaning agents, but also meets the new requirements for drinking water hygiene. This is particularly relevant in hospitals, where clean, hygienically safe water is essential.

With the revised directive coming into force, it is necessary that all components that come into contact with drinking water have a tested and certified drinking water approval. Seals must be resistant to microbial contamination and must not release any harmful substances into the water. Our Micro seals not only meet these requirements, but exceed them in many ways. They prevent microorganisms or contaminants from entering the water and thus contribute to safe and hygienic dental treatment.

EU Drinking Water Directive

Directive (EU) 2020/2184 of the European Parliament and of the Council on the quality of water intended for human consumption

The revised EU Drinking Water Directive, which introduces stricter limits for contaminants and expanded monitoring of drinking water quality in all EU member states, will come into force on January 12, 2025. In addition, specific hygiene regulations for materials and products that come into contact with drinking water will become mandatory from December 31, 2026. These new regulations, which include standardized certification and labeling throughout Europe, are intended to increase product safety and further strengthen consumer health protection. Manufacturers of products such as pipes, valves and pumps must adapt their processes by this date to meet the new requirements.

Our Services for Micro Seals

Micro Seals in Other Application Areas

Join Us!

Experience Freudenberg Sealing Technologies, its products and service offerings in text and videos, network with colleagues and stakeholders, and make valuable business contacts.

Connect on LinkedIn! open_in_new