Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

Micro Seals at the Hospital Reception

Precision Components in Micro Format

Patients and visitors expect a pleasant atmosphere and the highest standards of hygiene and efficiency in a hospital reception area. Micro Parts play a crucial role in this context, because these precision components have been specially developed for the high hygiene requirements that prevail in hospitals. Even in the reception area of a clinic, they ensure the functionality and reliability of devices such as coffee machines.

Hygienic Precision for Every Coffee

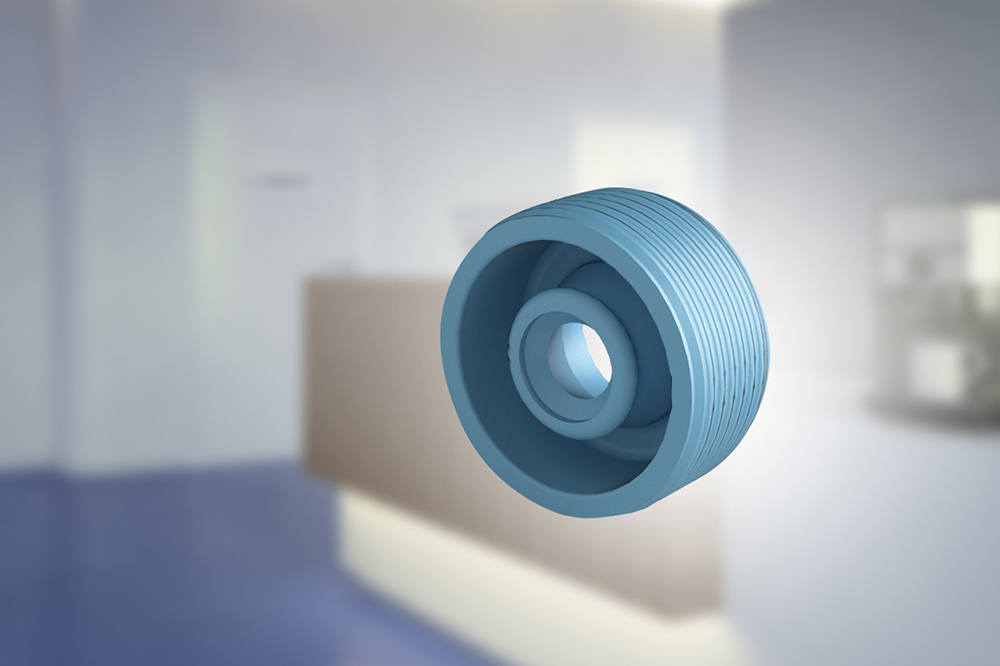

Micro-Simmerring®: Radial Shaft Seal With Precision and a Long Service Life for Coffee Machines

In a clinic, food hygiene is of the utmost importance. High-precision Micro Seals such as the Micro-Simmerrings® from Freudenberg Sealing Technologies ensure that the coffee machine not only delivers perfect coffee, but also meets hygiene standards.

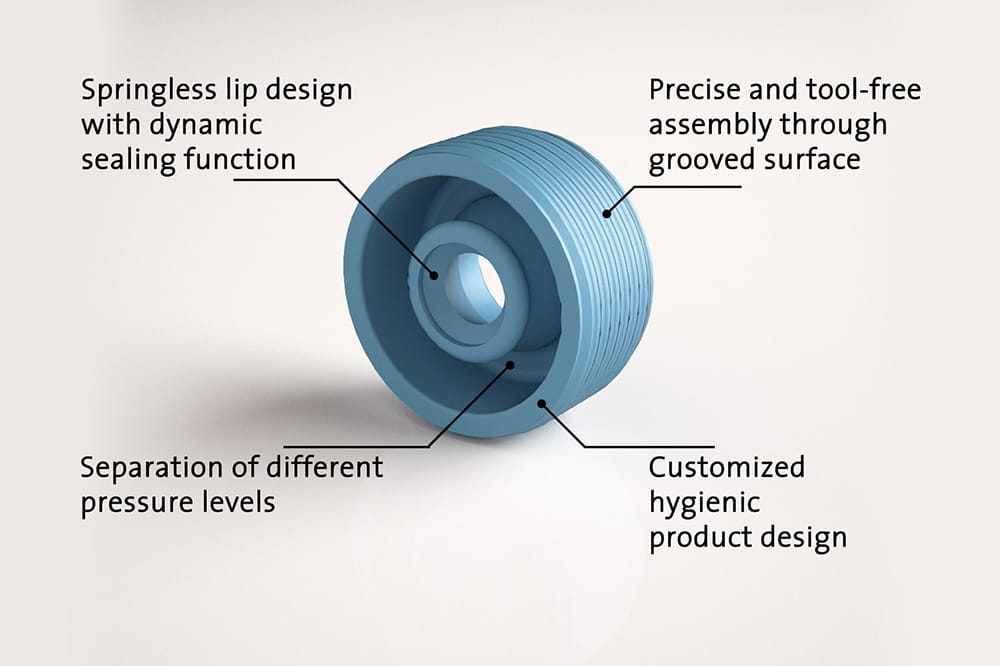

The Micro-Simmerring® is a high-precision sealing solution that was specially developed for the reliable sealing of radial shaft seals with diameters of 1 mm to 3 mm. In applications such as micropumps, microdrives and microactuators, it is capable of handling shaft speeds of up to 20,000 rpm, depending on the operating conditions. The miniature radial shaft seal is particularly resistant to a wide range of media, including oil, food-grade cleaning agents, and aggressive chemicals. In addition, the Micro-Simmerring® covers a broad temperature range from -40 to 200°C.

Micro-Simmerring®: For Sealing the Smallest Shafts, e.g. In Pumps or Grinders

Wherever the smallest shafts need to be reliably sealed, the strengths of the Micro-Simmerring® come into their own. They prevent the leakage of fluids and protect the machine from the ingress of dirt into areas with rotating movements. Typical applications in industrial coffee machines include:

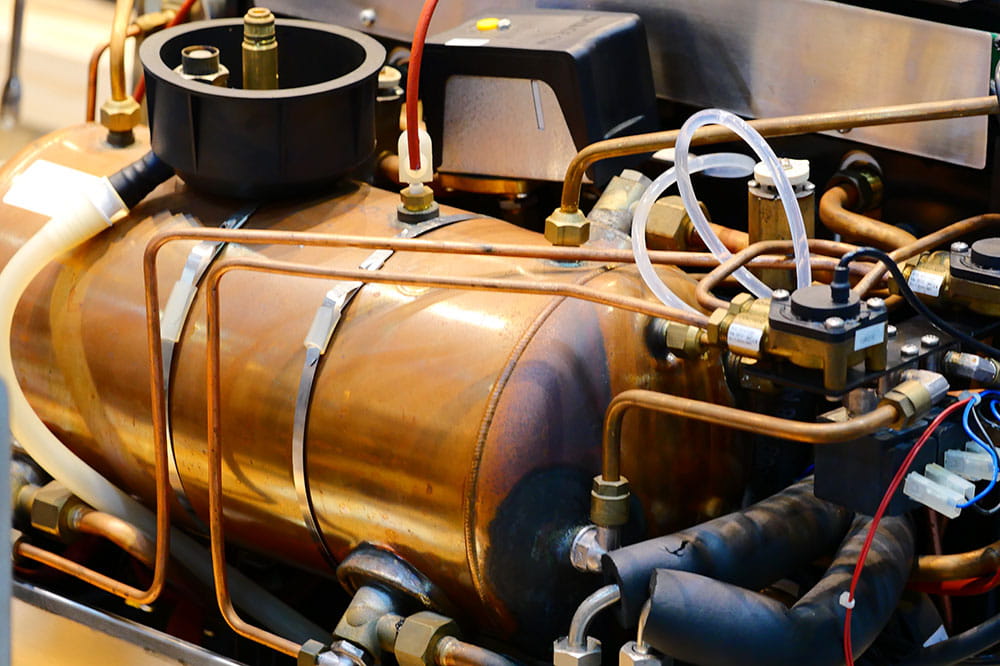

Pumps

Coffee machines, especially those with high-pressure systems such as espresso machines, require pumps to push the water through the system. Micro Simmerrings® seal the rotating shafts of these pumps and prevent water and other liquids from leaking out. This maintains the necessary high pressure in the system and protects the machine from damage caused by leaks.

Grinders and Mills

Many industrial coffee machines are equipped with grinders or mills to freshly grind coffee beans as needed. The millstones or grinding cones are driven by rotating shafts. These rotating shafts must be securely sealed to prevent coffee powder or oil from entering the interior of the drive unit and, conversely, to prevent lubricants from entering the grinding mechanism. Radial shaft sealing rings not only ensure the cleanliness and hygiene of the machine, but also the consistent quality of the ground coffee. High-performance seals such as the Micro-Simmerring® Seals extend the service life of the machine and keep the grinder in working order even under tough conditions.

All the Advantages of the Micro-Simmerring® Seal at a Glance:

-

Longer service life and reduced maintenance costs

-

Elastomer lip design without springs reduces friction to a minimum

-

Can be run dry for up to 20 minutes

-

Hardly any adhesion even under dry conditions

-

Seal design, size and materials can be customized to meet specific requirements

-

Series production within nine months of the pre-development stage

Food Certifications and Hygiene Standards for Coffee Machines

More than 10 million tons of coffee beans are produced every year. This makes coffee one of the most popular beverages worldwide. There are numerous ways of preparing coffee, depending on preferences, which can vary greatly from region to region. Coffee machines are often used for a quick coffee. Like all other appliances that come into contact with food, these machines must meet strict hygiene regulations. This applies especially to the components that come into contact with water, coffee or steam. Seals play a particularly important role in ensuring hygiene and safety. These seals must not only be leak-proof, but also prevent contaminants from entering the beverage.

Micro Seals, such as the Micro-Simmerrings® from Freudenberg Sealing Technologies, ensure that coffee machines not only deliver flavorful coffee, but also meet strict food safety standards.

Certificates, Guidelines, Laws and Standards

Global Regulations and Standards for Food Contact Materials

There are a number of regulations and guidelines in place around the world to ensure that materials that come into contact with food do not release harmful substances. These global standards ensure that coffee machines and their components meet the highest hygiene requirements:

European Union - Regulation (EC) No. 1935/2004

In the European Union, Regulation (EC) No. 1935/2004 is the governing regulation when it comes to materials and objects that come into contact with food. This regulation requires that all materials be manufactured in such a way that they do not transfer any components to food in quantities that are harmful to health. In addition, the composition or flavor of the food must not be altered by contact with the materials. For coffee machines, this means that the seals and other micro parts must meet the highest standards of hygiene and safety.

Germany - Food and Feed Code (LFGB)

In Germany, the Food and Feed Code (LFGB) in conjunction with the Consumer Goods Ordinance (BedGgstV) regulates all materials that come into direct contact with food. The LFGB lays down general principles for food safety and health protection. For seals in coffee machines, this means that the elastomers used must not only meet hygiene requirements, but also ensure that no potentially harmful chemicals are transferred to the beverages.

USA – FDA Title 21 CFR Part 177

In the United States, the U.S. Food and Drug Administration (FDA) defines the requirements for materials that come into contact with food. The regulations are set out in Title 21 CFR Part 177 and govern the approval of materials such as plastics and elastomers. Products certified as “FDA compliant” meet strict requirements regarding the release of chemicals and resistance to food.

China - GB 4806.1-2016 and GB 9685-2016

With its GB 4806.1-2016 and GB 9685-2016 standards, China has strict rules for materials that come into contact with food. These standards require that the materials used must not release any substances that are harmful to health and that they are processed in a hygienically flawless manner. The GB standards are particularly relevant for international manufacturers who want to offer their products on the Chinese market. Elastomers used in coffee machines must comply with the GB regulations, which means that they must be chemically inert and easy to clean.

Japan – Food Sanitation Law

In Japan, the Food Sanitation Law is of crucial importance when it comes to the safety of food contact materials. This law ensures that all materials that come into contact with food meet the highest safety standards. The elastomers used must be free of harmful chemicals and must not transfer any contaminants to the food. Such certifications play a particularly important role in clinical environments where strict hygiene requirements apply.

Global Regulations and Standards for Food Contact Materials

There are a number of regulations and guidelines in place around the world to ensure that materials that come into contact with food do not release harmful substances. These global standards ensure that coffee machines and their components meet the highest hygiene requirements:

European Union - Regulation (EC) No. 1935/2004

In the European Union, Regulation (EC) No. 1935/2004 applies to materials and articles that come into contact with food. This regulation demands that all materials must be so manufactured, that they transfer no components in a health-endangering quantity on food. In addition, the composition or taste of the food must not be altered by the contact of the materials. For coffee machines, this means that the seals and other micro parts must meet the highest standards of hygiene and safety.

Germany - Food and Feed Law (LFGB)

In Germany, the Lebensmittel- und Futtermittelgesetzbuch (LFGB) in conjunction with the Bedarfsgegenständeverordnung (BedGgstV) regulates all materials that come into direct contact with food. The LFGB establishes general principles for food safety and health protection. For seals in coffee machines, this means that the elastomers used must not only meet hygiene requirements, but also ensure that no potentially harmful chemicals get into the beverage.

USA – FDA Title 21 CFR Part 177

In the USA, the U.S. Food and Drug Administration (FDA) defines the requirements for materials that come into contact with food. The regulations are set out in Title 21 CFR Part 177 and govern the approval of materials such as plastics and elastomers. FDA-compliant products meet stringent requirements for chemical release and food resistance.

China - GB 4806.1-2016 and GB 9685-2016

With its GB 4806.1-2016 and GB 9685-2016 standards, China sets strict rules for materials that come into contact with food. These standards require that the materials used are free of harmful substances and are hygienically processed. The GB standards are particularly relevant for international manufacturers wishing to offer their products on the Chinese market. Elastomers used in coffee machines must comply with GB regulations, which means that they must be chemically inert and easy to clean.

Japan – Food Sanitation Law

In Japan, the Food Sanitation Law is crucial when it comes to the safety of materials that come into contact with food. This law ensures that all materials that come in contact with food meet the highest safety standards. The elastomers used must be free of harmful chemicals and must not transfer any contaminants to the food. Such certifications play a decisive role, especially in clinical environments where strict hygiene requirements apply.

Japan – Food Sanitation Law

In Japan, the Food Sanitation Law is crucial when it comes to the safety of materials that come into contact with food. This law ensures that all materials that come in contact with food meet the highest safety standards. The elastomers used must be free of harmful chemicals and must not transfer any contaminants to the food. Such certifications play a decisive role, especially in clinical environments where strict hygiene requirements apply.

Let’s Talk About Your Requirements for Your Specific Micro Seal!

Trust in quality and precision – trust in Freudenberg Sealing Technologies.

Get Expert Advice TodayHygienic Design: Safety Starts With the Details

In addition to the materials, which must meet strict hygiene requirements in the food industry, the design of the components themselves also plays a crucial role. Hygienic design ensures that the components used are not only safe and functional, but are also designed to allow easy cleaning and disinfection to avoid contamination.

By combining high-quality materials with an optimized design, Freudenberg Sealing Technologies develops micro parts that are both hygienic and durable. This is a crucial factor in meeting the strict hygiene standards in sensitive areas.

Micro-Simmerrings® Made of High-Performance Materials for Industrial Coffee Machines

Our Micro-Simmerrings® are designed to withstand the rigorous demands of hospital operations. They provide outstanding resistance to temperature fluctuations and aggressive cleaning agents, which increases their longevity and reliability. This minimizes maintenance and ensures continuous coffee machine function, even with intensive use.

FKM, FFKM, EPDM and Fluoroprene®: Food-Safe Materials With High Chemical and Temperature Resistance

Freudenberg Sealing Technologies develops Micro-Simmerrings® for the high demands of clinical environments. Depending on the application, they are made of high-performance materials such as FKM, FFKM, EPDM and Fluoroprene® XP.

These materials are resistant to the chemical effects of cleaning agents and extreme temperatures. In addition, the materials are approved for contact with food and drinking water. This ensures that the coffee machine always delivers hygienically safe coffee, regardless of the operating conditions.

Precise and Hygienic Fluid Handling Thanks to Micro Parts

In the hygienically sensitive environment of a hospital, fluid handling - the precise handling of liquids and gases - is of crucial importance. Whether the task is to dispense medication, control sterilization processes or handle cleaning and disinfection solutions, reliable and leak-proof control of these media is essential to ensure patient safety and process efficiency. Thanks to their high precision and reliability, micro parts from Freudenberg Sealing Technologies ensure that liquids and gases reach exactly where they are needed, while at the same time preventing any kind of leakage or contamination. This contributes significantly to maintaining the high standards of hygiene in a hospital.

Certifications Underscore the High Level of Materials Expertise at Freudenberg Sealing Technologies.

Precise and Hygienic Fluid Handling Thanks to Micro Seals

In the hygienically sensitive environment of a hospital, fluid handling, i.e. the precise handling of liquids and gases, is of crucial importance.

Whether it is the dosing of medications, the control of sterilization processes or the handling of cleaning and disinfecting solutions, reliable and leak-proof control of these media is essential to ensure the safety of patients and the efficiency of procedures.

Micro Seals from Freudenberg Sealing Technologies ensure that fluids and gases reach exactly the right place through their high precision and reliability, while preventing any kind of leakage or contamination. This contributes significantly to maintaining the high hygiene standards in a hospital.

Our Services for Micro Seals

Micro Seals in Other Application Areas

Join Us!

Experience Freudenberg Sealing Technologies, its products and service offerings in text and videos, network with colleagues and stakeholders, and make valuable business contacts.

Connect on LinkedIn! open_in_new