Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

Micro Seals in the Laboratory

Micro Seals for Laboratory Equipment

When Absolute Accuracy Is Essential

In today's hospitals, a wide range of highly sensitive laboratory equipment is used to make diagnoses, perform analyses and ensure that patients receive the best possible treatment. From diagnosis to drug development, the accuracy and repeatability of results depends on the quality of the equipment used. These devices must meet exacting requirements, especially when it comes to handling liquids and gases. Micro seals play an important role in many laboratory devices, from pipetting robots to HPLC systems. These micro components ensure that liquids are precisely dispensed, valves are reliably controlled and systems are securely sealed. In close cooperation with leading laboratory equipment manufacturers, the experts at Freudenberg Sealing Technologies develop customized solutions that are perfectly tailored to the specific requirements of each application.

Freudenberg Solutions in the Laboratory

Pipetting Robots: Precise Liquid Dispensing for Exact Results

Pipetting is one of the basic skills in a hospital laboratory. It is used in the production of dilution series, the transfer of reagents or the preparation of samples for analytical procedures. Errors in pipetting can lead to inaccurate results, falsified data and ultimately to costly repetitions of experiments. In the laboratories of large hospitals with high throughput rates, pipetting robots often prove their strengths. They work automatically and with great repeatability, processing even the smallest volumes quickly and precisely. To ensure that liquids are dispensed accurately and that no leaks occur that could falsify the results, rocker valves are of crucial importance.

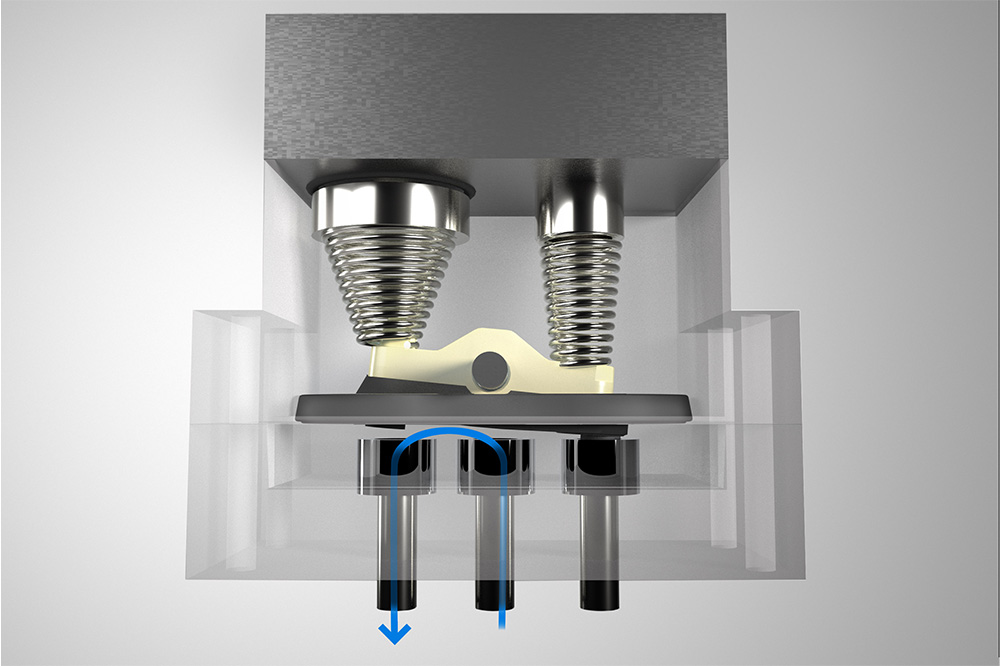

Rocker Valve: Precise Control of Liquid Dispensing

The rocker valve is an essential component of modern pipetting robots. The elastomer composite part consists of a plastic carrier part with a bearing bore, an elastomeric static sealing bead and two dynamic sealing pads. It regulates the flow of liquids through the pipette channels by opening and closing the lines with precision to allow precisely defined quantities of liquids to be taken up or dispensed. By controlling the flow of liquids with such accuracy, rocker valves help to minimize the risk of contamination and ensure that the dosage is precise. This is particularly important for highly sensitive applications in research and diagnostics. Micro seals such as the rocker valve are therefore essential to ensure the accuracy and reliability of the tests and analyses performed. The precise manufacturing of these micro seals from a single tool, with tight tolerances and high-quality materials such as EPDM and FKM, ensures that the valves function reliably even under demanding conditions.

All the Advantages of the Rocker Valve at a Glance:

-

Maximum precision

Precise control and regulation of fluids, which is crucial for the integrity of laboratory results. -

Long service life

Robust materials such as EPDM and FKM ensure a long service life, even with intensive use and under demanding conditions. -

Versatility

Suitable for a wide range of laboratory applications, from diagnostics to analysis, thanks to a broad selection of elastomer-based materials.

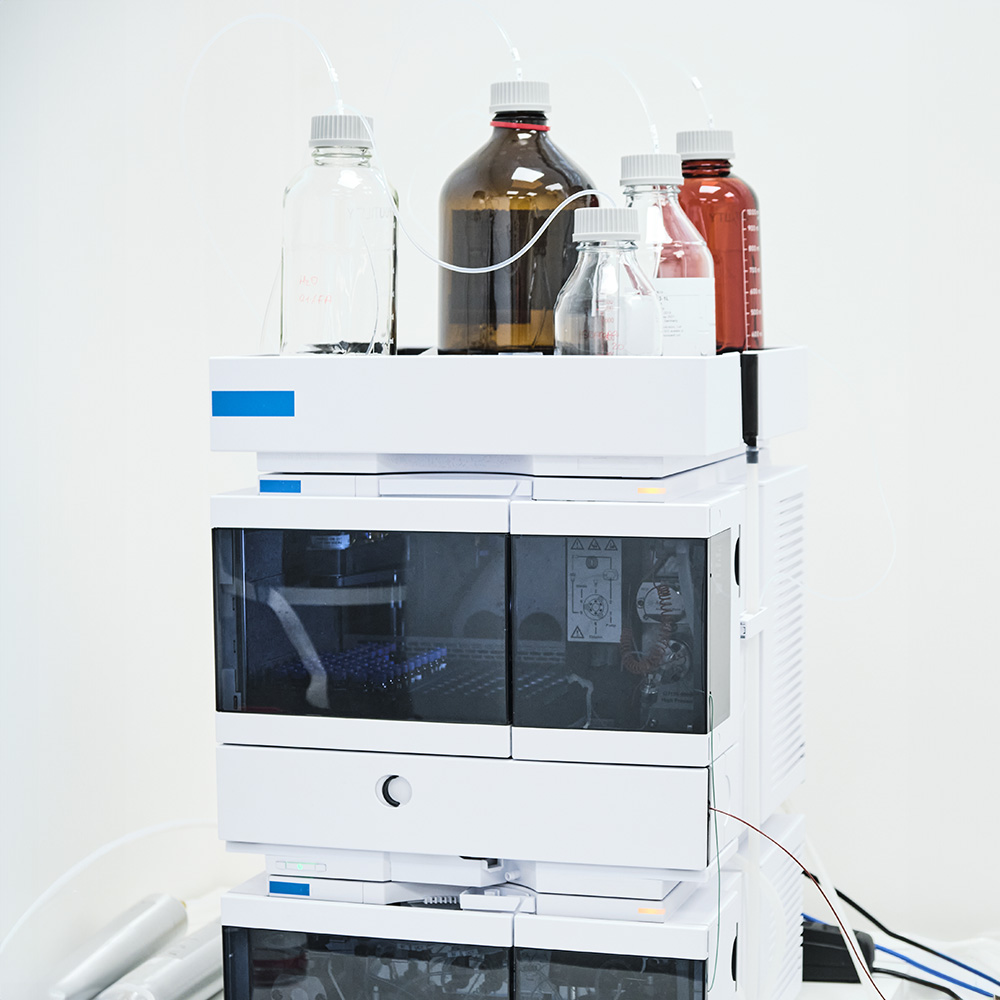

HPLC Instruments: Precise Separation and Analysis of Substances

High-performance liquid chromatography (HPLC) is a chemical-analytical method used to separate, identify and quantify semi-volatile and non-volatile compounds in liquid samples. HPLC instruments are used to separate and analyze substances at the molecular level. An HPLC system consists of four essential components: a pump for the mobile phase, an autosampler for sample injection, a column with the stationary phase for separating the sample components, and a detector for identifying the compounds. In addition, capillaries and connections are needed to ensure the continuous flow of the mobile phase and the sample through the system, as well as a CDS package to control the HPLC device, the separation, the detection and the evaluation of the results. Valve seat seals play a key role in HPLC applications by ensuring a secure seal between the valve and seat, preventing leaks that could affect the analysis.

Valve Seat Seals: Ensuring Tight Connections in HPLC Systems

The main task of a valve seat seal in an HPLC system is to prevent the flow of liquids when the valve is in the closed position. The quality of the micro-component is of crucial importance here, since even the smallest leaks can lead to erroneous measurement results. For this reason, Freudenberg Sealing Technologies develops valve seat seals that meet the highest standards by using materials that are both chemically resistant and mechanically stable. FKM and FFKM are the preferred materials because they are resistant to aggressive media and offer a long service life.

All the Advantages of the Valve Seat Seal at a Glance:

-

Chemical resistance

High resistance to aggressive media, which increases the safety and reliability of the devices. -

Reliable sealing function

Prevents leaks that could lead to incorrect results, thus ensuring the accuracy of the separation and analysis. -

Long service life

Robust and durable materials ensure a long service life for the valve seat seals and thus for the devices as a whole.

Laboratory Analyzers: Exact Diagnoses Through Precise Control With Hammer Valves

Laboratory analyzers must work with extreme precision to deliver reliable and repeatable results. Wherever gases and liquids need to be controlled in analyzers, hammer valves are an important component. Hammer valves work by applying a mechanical blow to the valve body, which quickly opens or closes the valve. This mechanism enables very precise control of the flow of liquid media and gases. The “hammer blow” ensures a fast movement that locks the valve in the desired position, which is important to prevent leakage and ensure stable control.

The robust design makes hammer valves particularly suitable for applications where high precision, reliability and a fast response time are required. Freudenberg Sealing Technologies manufactures these Micro seals with close tolerances and from high-quality materials such as EPDM and FKM. This ensures that the valves perform reliably even in demanding applications.

All the Advantages of the Hammer Valve at a Glance:

-

Maximum precision

Precise control and regulation of liquids and gases, which is crucial for the integrity of laboratory results. -

Long service life

Robust materials such as FFKM ensure a long service life, even with intensive use and under demanding conditions. -

Versatility

Suitable for a wide range of laboratory applications, from diagnostics to analysis, thanks to a broad selection of elastomer-based materials.

Guidelines and Regulations for Laboratory Equipment

In laboratories, especially in clinical environments, strict regulations for hygiene, safety and reliability are essential. Various specific guidelines and standards ensure that laboratory equipment and its components, such as seals, meet these high requirements.

The most important requirements include:

ISO 15189

This standard places high demands on the quality and competence of medical laboratories and also includes the testing and maintenance of the equipment used to ensure its functionality.

ISO 17025

This international standard defines the requirements that laboratories must fulfill to ensure precise and reliable measurement results. This also includes the high accuracy of the laboratory equipment used.

DIN EN 61010

This standard describes the basic safety requirements that apply to electrical laboratory equipment to ensure safe operation.

FDA (Food and Drug Administration)

In the United States, laboratory equipment that comes into contact with biological samples must meet the strict requirements of the FDA. This includes the use of hygienic materials and the ability to thoroughly disinfect the equipment.

Our Services for Micro Seals

Customized Solutions for Laboratory Applications

Laboratory equipment must not only be precise, but also reliable. Every application has its specific requirements, and Freudenberg develops customized Micro seals that are precisely tailored to these requirements. From the selection of materials to manufacturing, each component is developed to meet the highest standards and ensure reliable operation of laboratory equipment.

By working closely with customers, Freudenberg Sealing Technologies is able to develop solutions that are perfectly tailored to the respective applications. Whether it's pipetting robots, HPLC devices, ventilation systems or laboratory analyzers, Micro seals help ensure that these devices perform their tasks accurately and reliably.

Would you like to learn more about our customized solutions for laboratory equipment? Contact us – we will be happy to advise you in detail!

Micro Seals in Other Application Areas

Join Us!

Experience Freudenberg Sealing Technologies, its products and service offerings in text and videos, network with colleagues and stakeholders, and make valuable business contacts.

Connect on LinkedIn! open_in_new