Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

Micro Seals in the Operating Theater

Micro Seals in the Operating Theater - Precision in Life-Saving Moments

Micro seals from Freudenberg Sealing Technologies play a key role wherever precision and reliability determine the success of an operation and the life of a patient. From vital anesthesia machines to modern ventilation systems, our high-precision micro seals ensure that everything runs smoothly in the background. At critical moments, it is often the smallest components that make a big difference.

Medical devices have to function under the toughest conditions. They rely on the smallest sealing elements that offer precise control to ensure patient safety. The demands on these components increase with the complexity of the operations, requiring high standards in terms of materials, precision and hygiene.

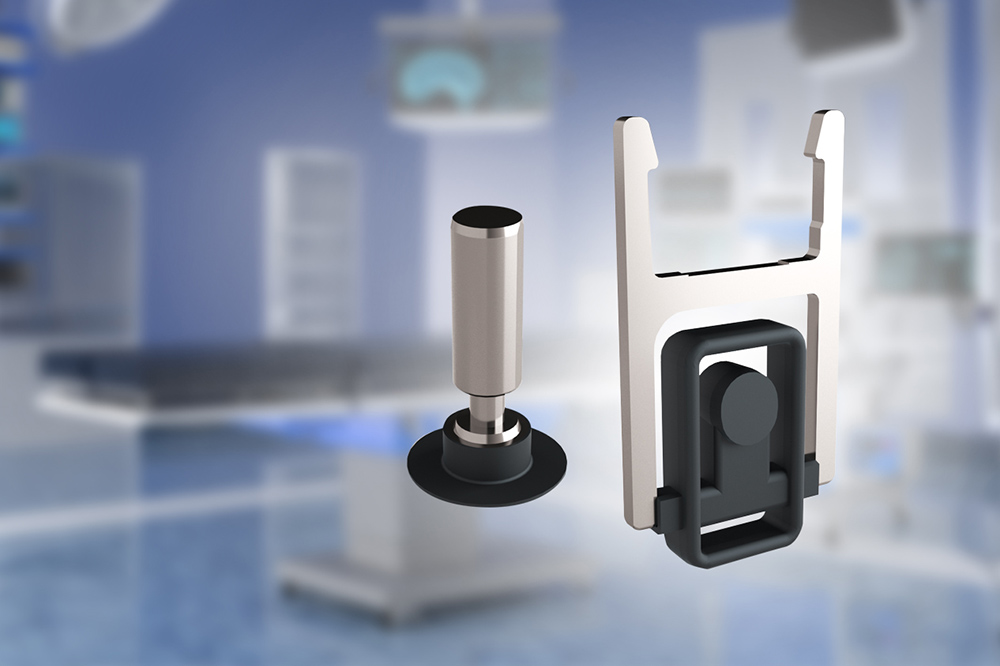

Freudenberg Seals for the Operating Room: Valve Pallets and Flipper Valve Seals

Safety Through Technology: Anesthesia Machines for Pain-Free Surgical Procedures

Medicine has made great strides in recent centuries, particularly in pain management. In the early days, pain was an unavoidable part of surgical procedures, but the development of modern anesthesia machines has fundamentally changed that. Patients can now undergo extensive and complex procedures without fear of pain.

This is where our micro parts come into play. At the heart of modern anesthesia machines are valve anchors that are responsible for the precise control of anesthetic gases. These tiny but crucial parts ensure the precise and safe administration of the right amount of gas – an indispensable aspect for the successful performance of pain-free surgery.

Valve Anchors: Precise Control of Anesthesia

The valve armature from Freudenberg Sealing Technologies is responsible for the precise dosage of anesthetic gases. In anesthesia machines, the micro seals play a key role in the function and control of the solenoid valve system by controlling the flow of anesthetic gases such as nitrous oxide, sevoflurane, desflurane or isoflurane. By controlling the armature, the valve can be opened or closed, thereby precisely metering the supply of gases. The armature must be particularly resistant to meet the high standards of precision, reliability and chemical resistance in such demanding environments.

The valve armature from Freudenberg Sealing Technologies is an elastomer composite part that was specially developed for demanding anesthesia applications. Thanks to its high-performance FFKM compound, it offers maximum chemical resistance and precision. The combination of metal and elastomer ensures reliable operation even under extreme loads.

All the Advantages of the Valve Armature at a Glance

-

Precision in the smallest dimensions

With a height of 9.1 mm, a diameter of 5.5 mm and a membrane thickness of 0.15 +/- 0.03 mm, the valve armature ensures precise control of the anesthetic in the smallest of spaces and minimizes the risk of dosage errors. -

Durability

Thanks to the robust materials used, the valve armature can withstand even the highest loads. -

Hygiene

The use of FFKM as a material ensures easy sterilization and minimizes the risk of cross-contamination.

Ventilation Equipment: Safe Breathing During Surgery

Controlling breathing is essential for patients undergoing long and complicated operations. Modern surgery is no longer imaginable without ventilation equipment. This equipment ensures that the patient is continuously and safely supplied with breathing gases during the procedure. Such devices, which require precise control of the breathing air, must be extremely reliable. Micro seals from Freudenberg Sealing Technologies play a crucial role in the safe and efficient operation of these devices.

The gas flow is controlled by flipper valve seals, which are available in miniature formats that are precisely tailored to the requirements of respirators. The valves ensure that breathing gases are delivered to the patient precisely and evenly, which is essential during general anesthesia.

Flipper Valve Seals: Precise Control in Respirators

The miniature flipper valve seals are used in respirators to control gas flow. They are responsible for regulating the precise flow of breathing gases, which is crucial for providing the patient with the right care during a surgical procedure. Precise control of gas flow ensures that the patient always receives the right amount of oxygen and other gases needed for safe and effective ventilation.

Flipper valve seals from Freudenberg Sealing Technologies are characterized by an extremely compact design and high reliability. With dimensions of just 13.5 x 7.4 x 1.76 mm and tolerances of up to ± 0.02 mm, they are specially designed for applications where space constraints and precise control are critical. They are manufactured to the highest standards of surface finish, mold release and flash removal to ensure proper function.

All the Advantages of the Flipper Valve Seal at a Glance

-

Customized development

Flipper valve seals are specially developed and produced according to customer requirements to ensure optimal performance in the respective application. -

High reliability

With over 10 million switching cycles, the flipper valve seal guarantees a long service life and reliable performance, even under the most demanding operating conditions.

Are You Looking for a Solution for Your Medical Application?

Let's talk about your requirements.

Get Expert Advice TodayLegal Requirements for Sterility and Hygiene in the Operating Theater

Micro seals from Freudenberg Sealing Technologies, such as valve armatures and flipper valve seals, meet all legal requirements and international standards to ensure safe and hygienic use in the operating theater.

Strict legal requirements and international standards govern hygiene in the operating theater. These include, among others:

ISO 13485

This standard specifies requirements for a comprehensive quality management system for medical device manufacturers, including ensuring sterility and hygiene.

RKI Guidelines

In Germany, the Robert Koch Institute (RKI) publishes specific guidelines for hygiene in operating rooms that include measures for infection prevention and for handling sterile materials.

FDA Guidelines

In the United States, the Food and Drug Administration (FDA) regulates the sterility requirements for medical devices and components used in the operating room.

The History of Anesthesia

The development of modern anesthesia has enabled a fundamental change in surgery, particularly in the operating room. Before the introduction of anesthetics, surgeries were often cruel and hectic procedures in which patients were operated on without painkillers. Doctors had to work quickly to minimize patient suffering.

A turning point came in 1846, when the first public demonstration of ether anesthesia took place in Boston. William Morton used ether to anesthetize a patient, paving the way for pain-free surgery. This method spread quickly, and other inhalational anesthetics, such as chloroform, were introduced soon after. Although these agents were more effective, they had some serious side effects, such as cardiac arrest or liver failure.

With the advancement of medicine, the early 1900s saw the introduction of local anesthetics such as cocaine and later lidocaine, which allowed for safer procedures. The discovery of muscle relaxants in the 1940s, such as curare, also revolutionized anesthesia by allowing relaxed and controlled surgery under general anesthesia.

Today, modern anesthetics such as sevoflurane, desflurane and isoflurane are predominantly used in inhalation anesthesia. These agents allow precise control of anesthesia and offer both rapid induction and short recovery times, significantly improving the treatment process for patients.

Reliable Materials for Critical Applications

Micro seals, such as valve anchors and flipper valve seals, are made of high-performance elastomers such as FKM and EPDM. These materials offer outstanding resistance to chemicals and high temperatures and can be easily sterilized – crucial properties for use in sterile operating environments.

Hygiene and Sterility in the Operating Room – An Indispensable Basis

Hygiene and sterility are of central importance in the operating room. Every surgical procedure carries risks, and even the smallest contamination can cause serious complications. For this reason, all devices and components in the operating room are subject to strict hygiene and sterilization requirements.

Micro seals, such as those developed by Freudenberg Sealing Technologies, play a major role in ensuring these high standards. In respirators and anesthesia systems, they not only ensure the precise control of vital gases, but are also designed to be easily cleaned and sterilized. Thanks to their high resistance to aggressive cleaning agents and sterilization methods, the sterile environment in the operating room is maintained.

Sterilization Techniques in the Operating Room

Various sterilization techniques are used in the operating room to ensure that all surfaces and equipment remain germ-free. The most common methods include:

- Autoclaving:This method uses saturated steam at high temperatures to kill microorganisms.

- Chemical sterilization: Special chemicals such as ethylene oxide (ETO) sterilize heat-sensitive devices and materials.

- UV radiation: UV light is used in surgical lights and air purification systems to keep surfaces and the air sterile.

Micro seals, such as gaskets and valves, must withstand these sterilization processes without losing their form or function. That is why Freudenberg Sealing Technologies relies on special elastomers that are particularly resistant to heat, chemicals and radiation.

Use of elastomer materials in various sealing media

| EPDM | NBR | HNBR | FKM | FFKM | |

| Water | ++ | + | + | (+) | ++ |

| Suds | ++ | + | + | (+) | ++ |

| CIP/SIP | + | - | (+) | ++ | ++ |

| Air | ++ | + | ++ | ++ | ++ |

| Fats | - | + | + | ++ | ++ |

Micro Seals in the Operating Room - Maximum Precision in Vital Equipment

In an environment where every second counts and patient safety is the top priority, it is often invisible components that make all the difference. Our micro seals are specially designed for the demanding requirements of the operating room. Their precision and reliability make them indispensable components in the control and monitoring of medical equipment.

Our Services for Micro Seals

Micro Seals in Other Application Areas

Join Us!

Experience Freudenberg Sealing Technologies, its products and service offerings in text and videos, network with colleagues and stakeholders, and make valuable business contacts.

Connect on LinkedIn! open_in_new